Introduction:

Tungsten steel round bar is one of the widely used materials of tungsten steel. It is named because of its cylindrical round bar shape. It has the advantages of high hardness, good bending strength, corrosion resistance, no rust, wear resistance, etc. Tungsten steel round bar is mainly used to make high-speed tungsten steel drill bit, tungsten steel milling cutter, tungsten steel boring tool, tungsten steel micro drill, tungsten steel needle punch, tungsten steel wear rod, tungsten steel bearing, etc. it can be used to process aluminum alloy, PCB, glass fiber reinforced materials, brake materials, graphite, high temperature alloys, stainless steel, titanium alloys, hardened steel and other materials or used in mechanical wear parts. Tungsten steel round bars are a widely used carbide materials and can be precision machined to various sizes to meet the needs of the mechanical industry, especially for tungsten steel wear bars for electric spindle machining.

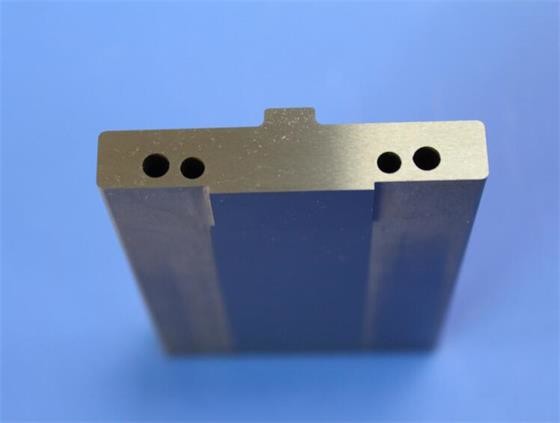

Tungsten steel grinding rod wear-resistant parts is produced according to the mechanical electric spindle equipment and customer drawings. Size specifications are different, the longest tungsten steel rod is 360mm, completely exceed the conventional size. Drawing data reference is as follows:

The maximum outer diameter specification is φ29.4*331, the overall outer diameter concentricity requirement is 0.002, the outer circle finish is 0.8, and the head axiality is 0.005. The precision processing requirement of such a large specification is also strict for the material itself.

Tungsten steel, with high hardness, high strength and extremely stable physical properties, are excellent material choices for wear-resistant parts. Long-lasting service life and wear resistance are especially important for the operation of electric spindles. We provide tungsten steel grinding rods, tungsten steel bushings, tungsten steel sleeves and other series of products, providing non-standard size precision tungsten steel grinding rod according to customers drawings. The specifications of conventional tungsten steel casing and tungsten steel pipe are as follows:

1. The maximum outer diameter: φ74mm

2. The minimum outer diameter: φ5mm

3. The maximum inner diameter: φ68mm

4. The minimum inner diameter: φ0.1mm

5. Maximum length of tungsten steel pipe: φ0.1mm

Technical parameters:

Tungsten steel grinding rod wear-resistant parts is produced according to the mechanical electric spindle equipment and customer drawings. Size specifications are different, the longest tungsten steel rod is 360mm, completely exceed the conventional size. Drawing data reference is as follows:

The maximum outer diameter specification is φ29.4*331, the overall outer diameter concentricity requirement is 0.002, the outer circle finish is 0.8, and the head axiality is 0.005. The precision processing requirement of such a large specification is also strict for the material itself.

Tungsten steel, with high hardness, high strength and extremely stable physical properties, are excellent material choices for wear-resistant parts. Long-lasting service life and wear resistance are especially important for the operation of electric spindles. We provide tungsten steel grinding rods, tungsten steel bushings, tungsten steel sleeves and other series of products, providing non-standard size precision tungsten steel grinding rod according to customers drawings. The specifications of conventional tungsten steel casing and tungsten steel pipe are as follows:

1. The largest outer diameter: φ74mm

2. The smallest outer diameter: φ5mm

3. The largest inner diameter: φ68mm

4. The smallest inner diameter: φ0.1mm

5. Maximum length of tungsten steel pipe: 360mm