Introduction:

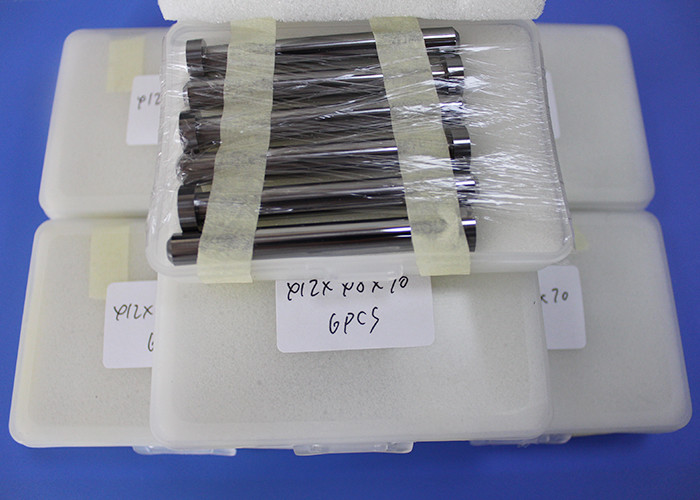

Carbide round rod is a kind of hard alloy material. Its main component is tungsten carbide powder, cobalt powder and binder mixing extremely small amount of precious metal. By powder metallurgy method, it is sintered at 1300 °C , having the advantages of high hardness, high strength, high temperature resistance, high wear resistance and good impact toughness. Carbide round rods are mainly used for making high quality tungsten steel drills, tungsten steel milling cutters, drilling nozzles, punching pins and wear parts on industrial machinery. Carbide round rods with micropores are designed for certain special requirements.

The conventional carbide single-hole round rod is mainly with the inner hole size of φ2-φ3 and above, and the inner hole specification of the cemented carbide micro-hole round rod is mainly between φ0.08-φ0.5, such as specifications of φ3.3*φ0.1*330, it is mainly suitable for precision machining, like carbide nozzles, tungsten carbide nozzles, tungsten steel nozzles, etc.

Technical parameters:

The common size specifications of carbide round rod with micropores and tungsten steel round rod with small hole:

- φ3.3*φ0.1*330

- φ3.3*φ0.08*330

- φ4.3*φ0.2*330

- φ5.3*φ0.3*330

- φ6.3*φ0.1*330

- φ5.3*φ0.5*330

- φ5.3*φ0.8*330 etc.

Model indication: D×d×L

Outer diameter (D) (mm) | Tolerance (Tol) (mm) | Aperture (d) (mm) | Tolerance (Tol) (mm) | Length (L) (mm) | Tolerance (Tol) (mm) | Concentricity (C) (mm) |

| 2.5 | +0.20~0.50 | 0.3 | ±0.10 | 330 | 0~+0.5 | 0.2 |

| 4.0 | +0.20~0.50 | 1.0 | ±0.15 | 330 | 0~+0.5 | 0.2 |

| 6.0 | +0.20~0.50 | 1.0 | ±0.15 | 330 | 0~+0.5 | 0.2 |

| 8.0 | +0.20~0.50 | 1.5 | ±0.15 | 330 | 0~+0.5 | 0.2 |

| 10.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+0.5 | 0.25 |

| 12.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+0.5 | 0.25 |

| 14.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+0.5 | 0.25 |

| 16.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+0.5 | 0.25 |

| 18.0 | +0.40~0.80 | 3.0 | ±0.25 | 330 | 0~+0.5 | 0.3 |

| 20.0 | +0.40~0.80 | 3.0 | ±0.25 | 330 | 0~+0.5 | 0.3 |

| 22.0 | +0.40~0.80 | 3.0 | ±0.25 | 330 | 0~+0.5 | 0.3 |

| 24.0 | +0.40~0.80 | 4.0 | ±0.30 | 330 | 0~+0.5 | 0.3 |

| 26.0 | +0.40~0.80 | 5.0 | ±0.35 | 330 | 0~+0.5 | 0.3 |

| Outer diameter(D) (mm) | Outer diameter tolerance (mm) | Hole size (mm) | Hole diameter tolerance (mm) | Concentricity (C) (mm) | Length (L) (mm) | Length tolerance (Tol) (mm) |

| Փ2.5 | +0.20~+0.50 | 0.3 | ±0.10 | 0.2 | 330 | 0~+0.5 |

| Փ 4.0 | +0.20~+0.50 | 1.0 | ±0.15 | 330 | 0~+0.5 |

| Փ 6.0 | +0.20~+0.50 | 1.0 | ±0.15 | 330 | 0~+0.5 |

| Փ 8.0 | +0.20~+0.50 | 1.5 | ±0.15 | 330 | 0~+0.5 |

| Փ 10.0 | +0.30~+0.60 | 2.0 | ±0.20 | 0.25 | 330 | 0~+0.5 |

| Փ 12.0 | +0.30~+0.60 | ±0.20 | 330 | 0~+0.5 |

| Փ 14.0 | +0.30~+0.60 | ±0.20 | 330 | 0~+0.5 |

| Փ 16.0 | +0.30~+0.60 | ±0.20 | 330 | 0~+0.5 |

Advantages:

Cemented carbide concept: Composite material consisting of refractory metal compound (hard phase) and binder metal (bonded phase) produced by powder metallurgy.

1. High hardness and high wear resistance

2. High elastic modulus

3. High compressive strength

4. Good chemical stability (acid and alkali corrosion, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient. The thermal conductivity and electrical conductivity is similar to iron and its alloys.

Application: modern tool materials, wear resistant materials, high temperature and corrosion resistant materials.