0.48-0.53mm High Precision Laser Soldering Tungsten Carbide Tin Ball Nozzle

With just φ0.48-0.53mm laser beam inlet hole, where the carbide nozzle laser heating tin ball to do soldering purpose.

It took us, Sanxin carbide technician team, six years to accomplish our end, carbide nozzle service life more than 400,000 times per unit.

Thus, to meet a huge consumption need for soldering machines, to improve the production efficiency and to save maintenance cost.

Size 1) D1.0*0.48*A20*5.8L*d1.5

Size 2) D1.0*0.53*A20*5.8L*d1.5

And your customized sizes based on drawing is available.

Strong Points:

Sanxin Tungsten Carbide Manufacture, an expert who've been specialized in Carbide customizing industry for 20 years.

Can do almost all tungsten carbide products in China.

1, National high-tech enterprise certification

2, Processing High tolerance accuracy ±0.002mm

3, Wear-resistant, heat-resistant and anti-corrosion

Standard Material Specifications:

| Grain size(um) | 0.4~2.0 |

| Co% | 6.0~20 |

| Density g/cm3 | 13.96~14.85 |

| Hardness HRA | 89.5~93 |

| Flexural strength Mpa | 3200~4500 |

| Young's Modulus Gpa | 570~620 |

Application:

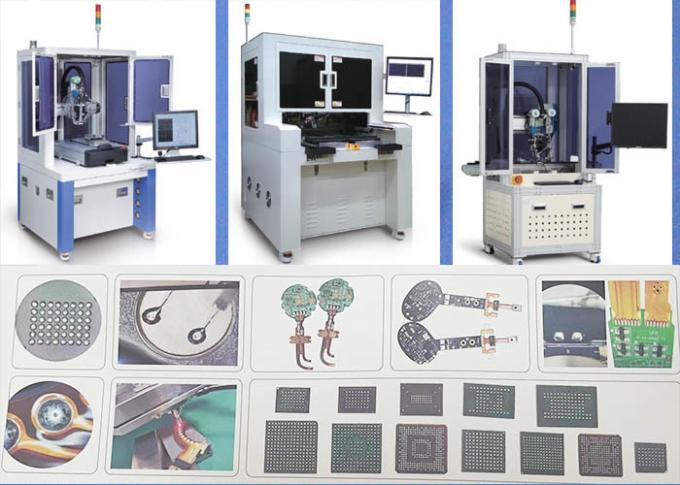

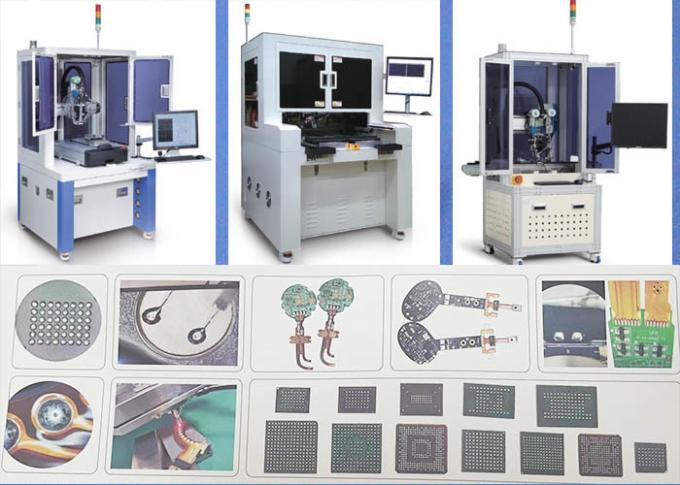

The advanced laser Soldering system is for PCB or component package by laser beam as heat reservoir.

- Excellent quality repeatability of assuring the fixed soldering volume.

- Precise soldering by non-contact method and laser beam size control.

Working Parameter:

| Laser Power | 20-300W |

| Wavelength | 880-1064nm |

| Tin ball diameter | 0.1-0.5mm |

| Soldering speed | 3-6pcs/s |

Packing:

Safe plastic box packing with fancy inner holder insert like eva.