Introduction:

We specialize in the production and processing of tungsten alloy products such as tungsten alloy, tungsten parts, tungsten processing, etc.

Tungsten is a metal element with an atomic number of 74 and an atomic weight of 183.84. It is steel gray or silver white, of high hardness, high melting point, and no air erosion at normal temperature. It is mainly used to manufacture filament, wear-resistant hard alloy, super hard die; also use in optical instruments and chemical instruments. The chemical element symbol of tungsten is W, with the atomic radius 137 picometers, and the density 19.35 g/cm³, which belongs to the sixth period (second long period) of the periodic table, VIB family. Tungsten is mainly a hexavalent cation, and its ionic radius is 0.68×10-10 m. Because W6+ has a small ionic radius, high electrovalence, strong polarization, and easy formation of complex anions, tungsten is mainly composed of complex anions [WO4]2-, combined with Fe2+, Mn2+, Ca2+ and other cations to form wolframite or white tungsten ore precipitation. The smelted tungsten is a silvery white shiny metal with a very high melting point, high hardness, low vapor pressure, low evaporation rate and relatively stable chemical properties.

Tungsten is refractory metal with a highest melting point. Generally, metal with a melting point higher than 1650 ° C, with certain reserve and having a melting point higher than zirconium (1852 ° C) are called refractory metals. As a refractory metal, the most important advantage of tungsten is its good high-temperature resistance and good corrosion resistance to molten alkali metals and vapors.

Technical parameters:

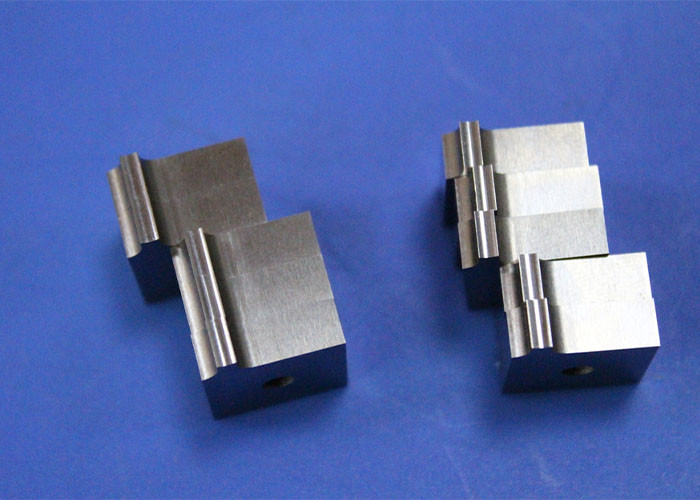

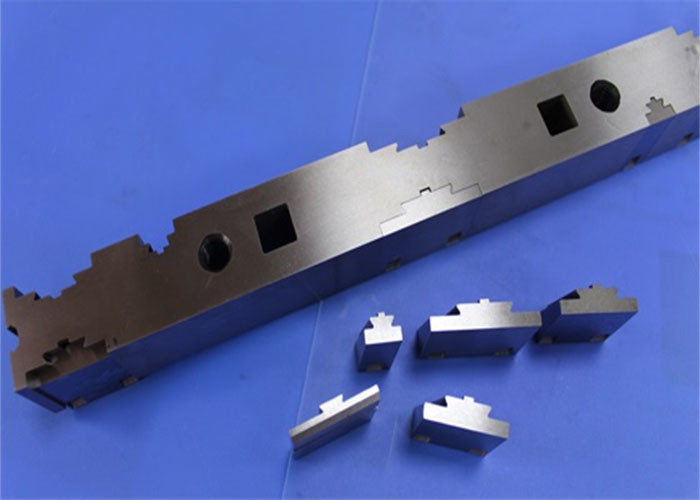

We specialize in the production of tungsten parts according to the specific requirements of customers. It is mainly used for high temperature resistance, medical shielding and counterweight.

Advantage:

National high-tech enterprise certification, the accuracy of the shape tolerance of tungsten cemented carbide is ±0.002.

Our company is equipped with a series of professional processing equipment and rich experienced technical workers. From tungsten steel raw material to precision tungsten steel parts, we can produce cemented carbide die parts according to customer's drawings or sample accuracy requirements. The requirements for the production and processing of cemented carbide precision parts are precision level. This requires strong technical support, rich experience and advanced production equipment to meet μ-level precision tolerance.