Introduction:

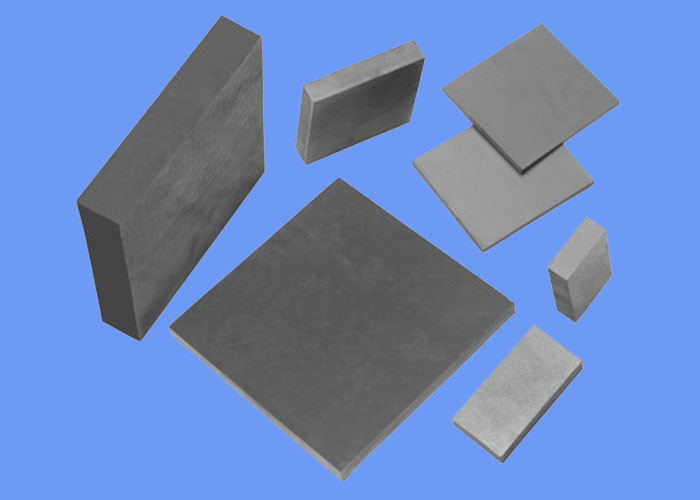

3D glass hot-bending tungsten steel soaking plate is mainly used for high-temperature hot bending forming operation of 3D mobile phone glass hot bending machine. We are specializing in the production of 3D glass hot bending. The most important production process of mobile phone 3D glass screen is hot bending forming. The heating temperature will reach 850 ° C ~ 1150 ° C or even higher. In such high temperature working environments, it has special requirements for 3D hot bending glass tungsten steel mold. Moreover, the glass material has a strong corrosive effect under high temperature conditions. It is necessary to ensure the compactness and high hardness of the soaking plate, also need to ensure high temperature resistance, heat conduction and extremely high corrosion resistance without deformation. This is undoubtedly a new material application requirement and challenge for powder metallurgy new materials.

As a professional manufacturer of tungsten steel processing manufacturer, our company is a comprehensive enterprise integrating powder metallurgy raw material production, alloy production, research and development, and alloy blank deep processing. We have complete production chain and specialize in the production of tungsten steel for 3D glass hot bending forming production. We have technical advantages and production strength in tungsten steel soaking plate. From the preparation of raw materials, our company has professional WC powder production line. The hot plate uses the second-class high-temperature tungsten carbide powder as raw material. The WC powder has the advantages of complete crystal, small lattice distortion and uniform particle size. The 3D glass hot bending process requires tungsten steel soaking plate of high temperature resistance and corrosion resistance. Combining its own advantages, we adopt special WC powder as raw material, design special raw material formula, and strictly control the production process to ensure the high temperature stability, corrosion resistance and micro-deformation of the material. Data detection analysis and technical support guidance are provided by the State Key Laboratory of Powder Metallurgy Research Institute of Central South University.

Technical paramters:

Soaking plate, 3D glass hot bending machine heating plate, in order to ensure the yield of 3D glass, tungsten steel soaking plate must have the following conditions:

1. Good thermal conductivity can improve production efficiency.

2. High temperature without deformation, to ensure good yield of 3D glass production.

3. High temperature resistance and no oxidative deformation

4. high temperature and corrosion resistance, and long-lasting life!

The yield control of 3D glass hot bending is reflected in the cooperation work with graphite molds and the reasonable design station form of hot bending forming, which requires continuous improvement and better production efficiency in the production process. Thus, it can meet the tungsten steel soaking plate cooperation work of fifth, sixth and seventh stations of the hot bending machine.

Advantages:

We can provide high-quality powder metallurgy materials for the production and processing of glass hot bending machine. We can also provide tungsten steel soaking plates according to the requirements of the manufacturers. Currently, we have provided hot bending equipment for Dongguan, Shenzhen, Zhongshan, Huizhou, Harbin and other regions. And we also have provided robot manufacturer with the third generation of soaking plate glass and hot bending heat conduction plate. The detailed 3D hot bending machine glass soaking plate size is customized according to the requirements of manufacturers. The high temperature use requirements of mobile 3D glass production demands that the powder metallurgy materials are of high temperature resistance and corrosion resistance in long-term hot-pressing production conditions. Generally, the conventional operation needs 3 upper and 3 lower heat plates. That is one set of equipment needs to be equipped with 6 hot-rolled glass tungsten steel molds which are specially processed.