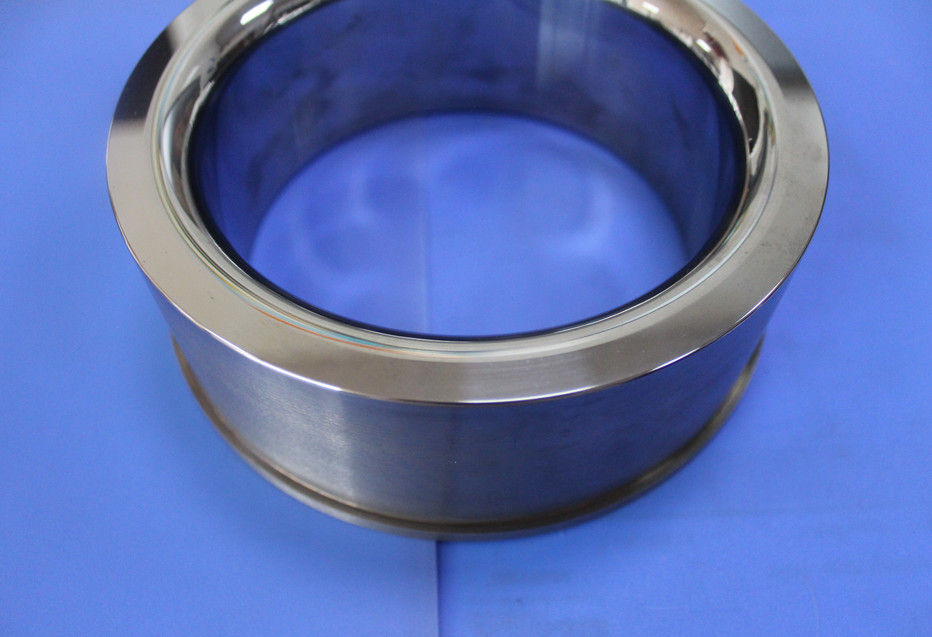

Acid Proof Tungsten Carbide Drawing Dies , OEM Carbide Threading Dies

Tungsten Carbide Drawing Dies Introduction:

Based on the detailed drawings of Bohai Drilling Engineering Technology Research Institute, we produce hard alloy drilling tools used as a key component of pulse restrictor.

As the industrial tooth, cemented carbide used as key part of drilling has better performance and efficiency than other materials. Cemented carbide products have provided oil exploration, drilling engineering and geological mining operations with powerful performance support. As a major manufacturer of hard alloys, the cemented carbide industrial chain in Zhuzhou leads the industry.

| Name | Acid Proof Tungsten Carbide Drawing Dies , OEM Carbide Threading Dies |

| Draw Format | Auto CAD/DWG/PDF ect |

| Tolerance | ±0.002mm |

| Hardness | Upon request |

| Mould size | Customized size |

| Production Application | Mobile/ laptop/ digital cameral/ HD digital TV/ automobile/ electron ect |

| Certificate | ISO 9001:2015 & ISO 14001:2015 |

| Surface Tratement | Polishing/ mirror polishing/ plating/ heat treatment or according to your parts |

| Precision Machining | CNC/ surface granding machine/ WEDM-HS/ sandik wire cutting/ EDM/ WIDA optical curve grinder ect |

| Measuring Instruments | Profile projector/ electronic height gauge/ CMM/ 2D measuring instrument/ vernier caliper/ microscope/ micrometer ect |

| Steel Material | KD20/ SKD11/ CD650/ 12EF/ YG15/ ASP23/ ASP60/ SKH-9/ Cemented Carbide ect |

| Mould Life | Depends on the steel material and your request |

| Main Service | Made-to-order |

Technical parameters:

Bohai Drilling Engineering Technology Research Institute provides detailed drawings, which require that the cemented carbide key components must have acid and alkali resistance, corrosion resistance, high wear resistance, and good impact resistance. these requirements are to achieve drilling. Our company adopts high-quality materials as the basis for deep processing operations.

Advantage:

As the industrial tooth, cemented carbide is best tool for manufacturing. As a cemented carbide production manufacturer in Zhuzhou, relying on Zhuzhou 60-year cemented carbide military production technology and industrial chain in Zhuzhou, we provide customers with high-quality hard alloy wear-resistant parts and non-standard shaped carbide products. Based on customer's drawing requirements, we select high-quality materials to satisfy customers' use demand.