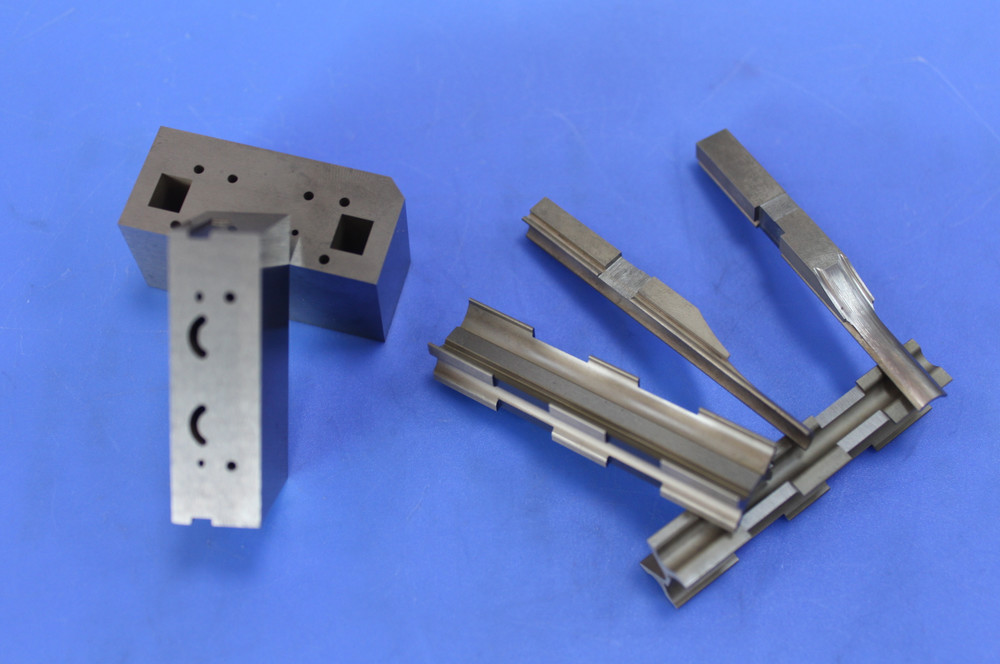

Anti Corrosion Cemented Carbide Mold For Gas Lift Valves Assembly

Cemented Carbide Mold Introduction:

1.Corrosion cemented carbide: cemented carbide electric corrosion layer is thinner, the micro defect of machined surface is reduced, and the surface quality of cemented carbide is improved.

2. Grain structure: tungsten carbide is more uniform, more rounded corners, more uniform stress distribution, improve cemented carbide

3. Service life: the same working condition is small, the service life is higher than be fore, 20%-100%.

As the industrial tooth, cemented carbide is a typical representative of super-hard wear-resistant products. The carbide grinding scraper used in steel slag processing plants is continuous process of mechanically treating steel slag. This requires extremely strong wear resistance of the scraper for continuous and long-lasting operation, especially for large equipment. The continuous working requirements need extremely high performance of the alloy product. The steel slag mechanical wear-resistant scraper is produced for China Metallurgical Group Co., Ltd., which is customized according to the corresponding drawings and is delivered within 25 working days. This show that we are prone to protect environment, conserve and recycle resource. We also welcome steel companies with this demand to contact us. We will produce high-abrasion materials according to the drawings to promote the recycling of environmental resources.

Technical parameters:

As the industrial tooth, cemented carbide has super wear resistance. The scraper used for large-scale mechanical equipment requires long-lasting wear-resisting work. Our company produce the steel slag mechanical wear-resistant scraper according to the drawing parameters of Jiangxi Iron and Steel Co., Ltd. The fine-grained tungsten carbide is used as raw material and is formed by professional pressure sintering process (Sinter-HIP). The scraper has high hardness and strength, belonging to super-high wear-resistant material.

Advantage:

The steel slag mechanical wear scraper is customer-made for the production operation of Jiangxi Steel Slag Treatment Plant of MCC Group. Thanks to the support and trust of China Metallurgical Science and Industry Group. We are proud and happy to produce the equipment for environmental protection and resources utilization.