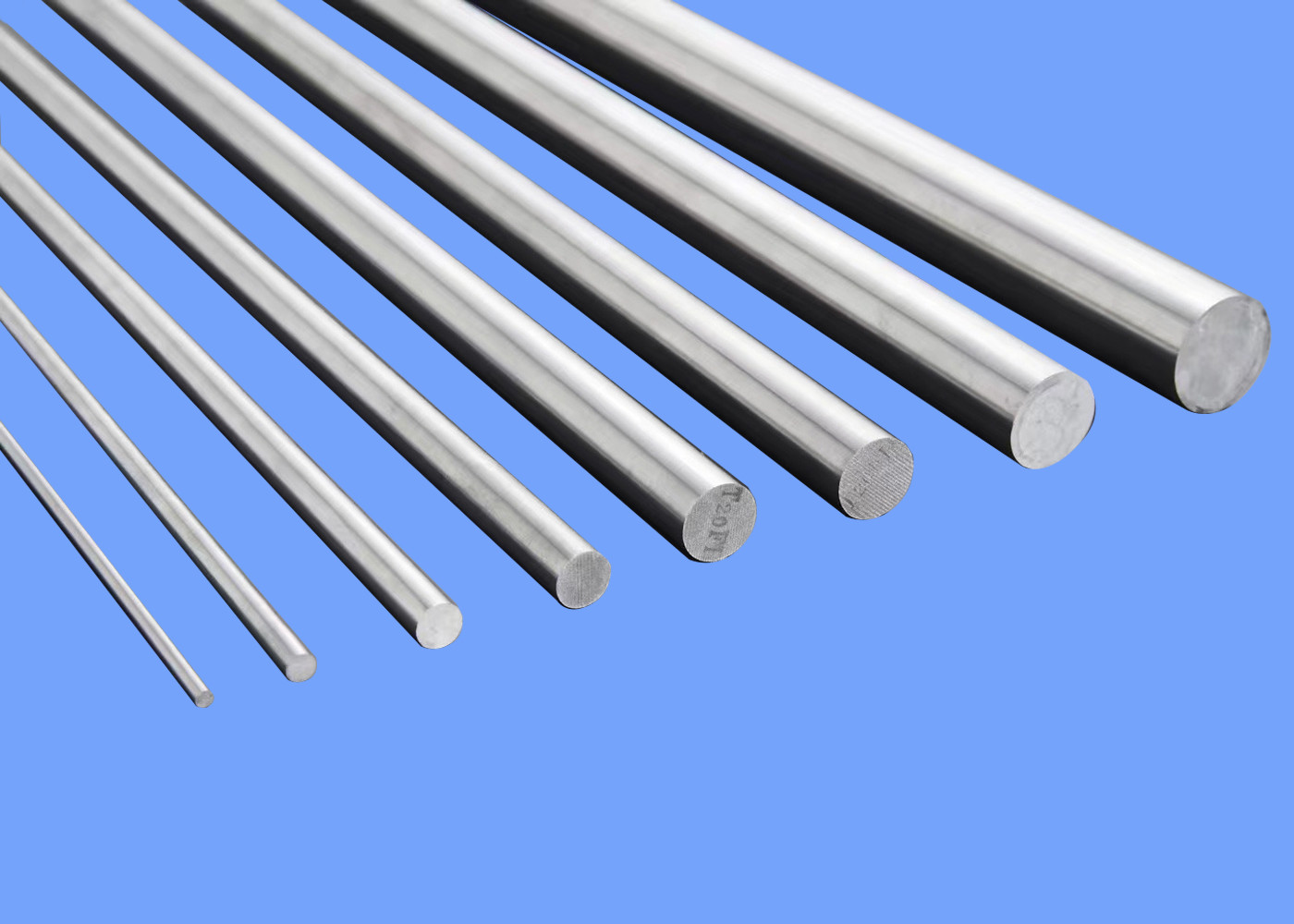

Wear-resistant heat-resistant and anti-corrosion tungsten W90NiFe4 rod

Specifications

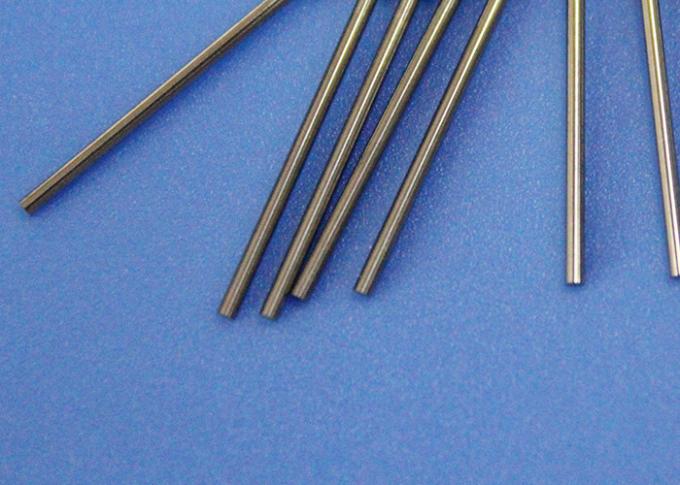

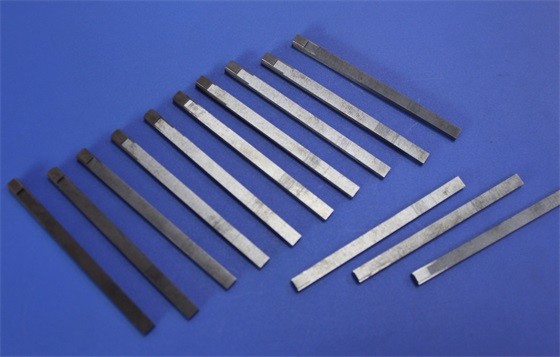

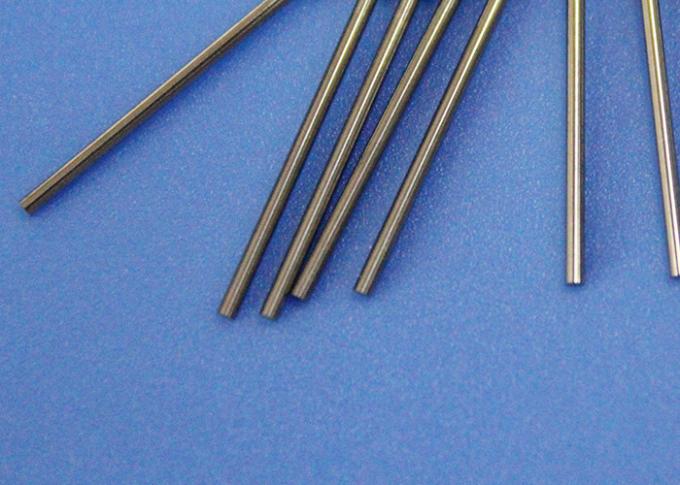

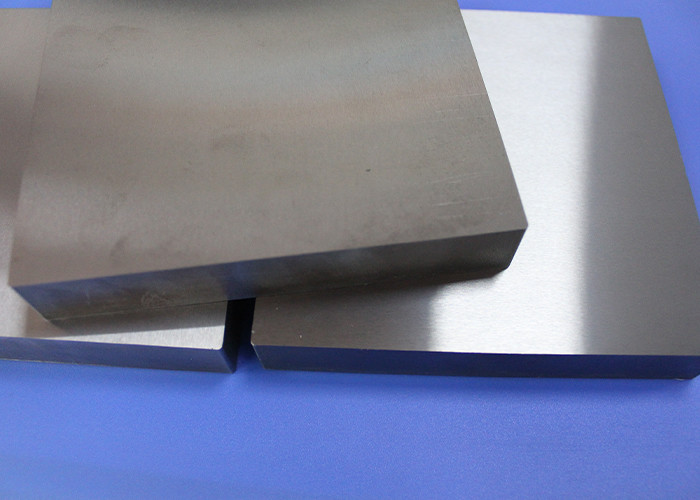

tungsten carbide saw tips:

-- Good abrasive resistance blank tungsten carbide tips.

-- Good heat and corrosion resistance.

Zhuzhou Sanxin Cemented Carbide is engaged in manufacturing,exporting and supplying a wide range of tungsten carbide tools, wear parts and components to suit different industries.

Quality and customer service are the core of our production. We have the capability toproduce parts ranging in different sizes and with a variety of grades available.

We have a team of highly qualified technical personnel with rich experience who provide complete service to the customers.

We could supply virouse tungsten carbide inserts for different purpose like bits, indusries e.t.c

Technical parameters:

From the production of raw materials to the processing of finished products, our company's hard alloy inserting surfaces are complete and perfect. The entire project is based on the cemented carbide production process. The ingredients are thoroughly mixed. → pulverized → dried → sieved, then added to the former → re-dried → sieved to obtain a mixture → mixed granule pressing → forming → low pressure sintering → sintered blank → inspection (non-destructive ultrasonic test) → blank dimensional accuracy inspection → EDM (or wire cutting) → rough grinding → fine grinding → polishing → inspection → labeling → packaging. Mass production of carbide insertion needle requires product consistency, which directly affects production efficiency. Whether custom-made or mass-produced, our company's carbide countersunk bolts always control each processing procedure to ensure the consistency of the carbide countersunk bolts.

Advantages:

Our company is specializing in producing and manufacturing hard alloy insert pins for precision mold customers. It is used with electronic ceramic injection molds. The precision requirements are very high, and the perfect consistency of products is the primary standard of this set of products. The tungsten carbide punching pin equipped in electronic ceramic precision mold is used in large number, and each insert pin is required to maintain good consistency. This requires that the finishing process must strictly control each processing procedure. Our company can produce the hard alloy insert pins according to the requirements of the precision mold manufacturer. The consistency of the products can be guaranteed, and the tolerance requirements are +0.002. The finish of the punch needles is required to be 0.2, which meets the highest requirements of applications in electronic ceramic injection molds.