Introduction:

Precision mold and equipment used in the processing of tungsten steel materials precision parts require good physical stability. Especially the durability and wear-resistance are undoubtedly the key point, which tungsten steel materials can fully meet these requirements. The ultra-hard metal material, tungsten steel, prepared by powder metallurgy technology, which is often referred to as cemented carbide, has the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance, small thermal expansion coefficient, etc. Widely used in industrial production and processing operations, it is one of the excellent tool materials. The use of tool materials is a good choice to improve work efficiency. This is what we said sharp tools make good work.

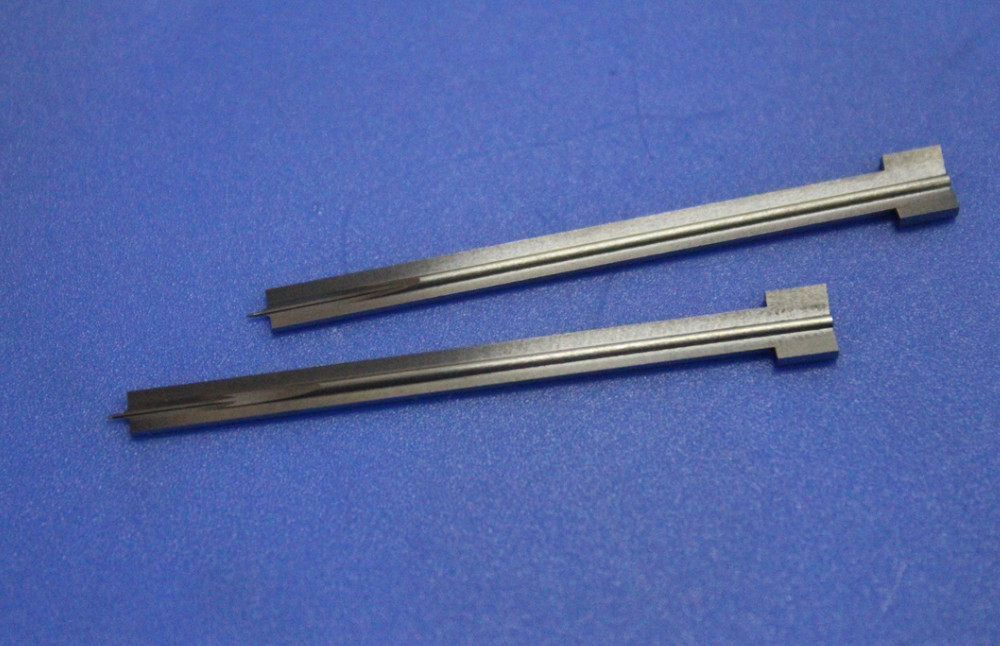

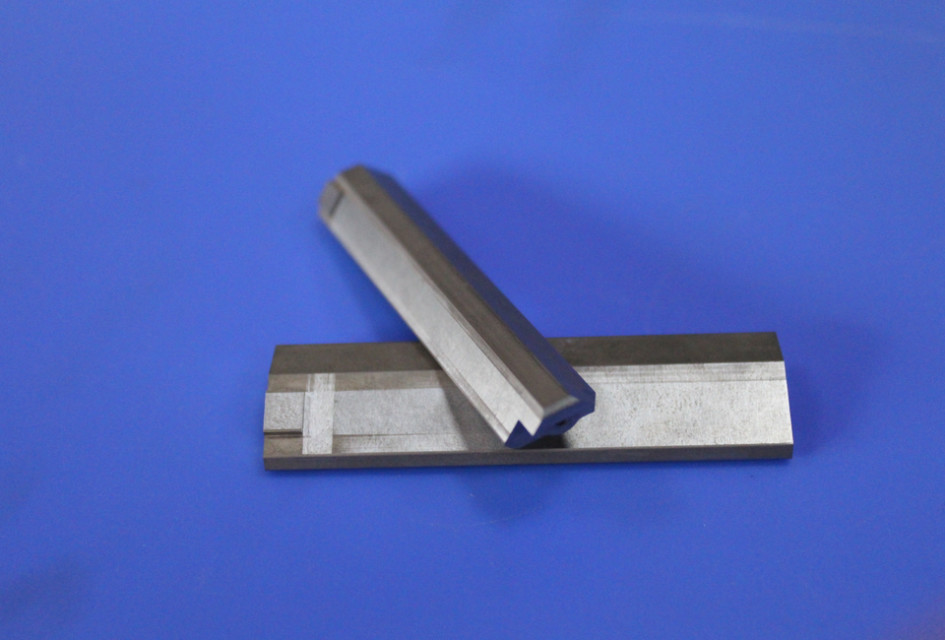

We can provide hard alloy moving insert pin, carbide insert pin, tungsten steel insert pin, etc. It is used with precision plastic molds and multi-station combination molds.

As a kind of industrial production and batch operation equipment, molds are the premise to improve production efficiency, especially high-quality and high-precision molds. The precision parts required for high-end precision molds are indispensable parts for normal operation, especially the tungsten steel processing mold inserts pin required for some precision work. Our company can provide plastic mold high-precision parts insert pins series products.

Technical parameters:

Tungsten steel material are chosen as processing for its material long-lasting physical properties, which goes beyond other metal tool materials. High wear resistance is one of the advantages of tungsten steel processing products. Under the actual working conditions of progressive molds, combined molds and multi-station molds, the tungsten steel mold materials are still durable. Thus, as a tool material, it is a good choice for mold products because of its high hardness, high strength and high wear resistance. According to the actual production operation, the processing of non-standard tungsten steel mold is taking the customer's specific drawing as the accuracy tolerance standard. The physical parameters of conventional tungsten steel forming pins can be referred to as follows:

- Grain size (um): 0.8 ~ 2.0

- Cobalt content (Co%): 6 ~ 10

- Density (g/cm³): 14.45

- Hardness HRA: 88 ~ 92

- Bending strength (Mpa): 3200 ~ 3800

- Young's modulus (Gpa): 570

- Compressive strength (Mpa): 4700

If the customer has special requirements, we can provide tungsten steel products with special requirements for production and processing.

Advantage:

As a representative of super-hard metals, tungsten steel is one of the best choices for industrial production of wear-resistant parts. As a cemented carbide production and processing manufacturer in Zhuzhou, we have been committed to providing high-performance tungsten steel processing products. From tungsten steel blank materials to tungsten steel deep processing, the tungsten steel precision parts tolerance is ±0.002, concentricity and parallelism can be 0.002. Precision tolerances of the precision mold parts can solve the overall accuracy requirements.