Introduction:

Carbide punching pin is finely grinded of hard alloy round bar. It has the properties of high precision, high hardness and good bending strength, suitable for hardware and electrical processing industry. It is generally used for punching on stamping dies to separate or plastically deform the material to obtain the required parts. Due to its characteristics of high hardness, long service life, corrosion resistance and no rust, it is widely used in industrial machining manufacturing and processing.

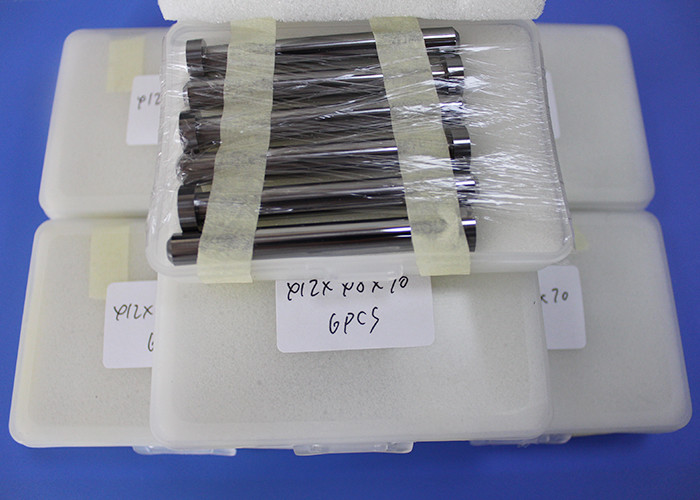

The tungsten carbide punching head equipped in electronic ceramic precision mold is used in large number, and each punching head is required to maintain good consistency. This requires that the finishing process must strictly control each processing procedure. Our company can produce the hard alloy punching head and insert pins according to the requirements of the precision mold manufacturer. The consistency of the products can be guaranteed, and the tolerance requirements are +0.002. The finish of the punch needles is required to be 0.2, which meets the highest requirements of applications in electronic ceramic injection molds.

As carbide punches and tungsten steel punch needles used in precision alloy mold, product consistency is a key factor, which will directly affect the service life of the mold and the dimensional accuracy of the product. not only the rough processing of carbide rods but also the fine-size processing of hard alloy punches, it is essential to strictly control the dimensional tolerance requirements and the consistency of mass production.

Technical parameters:

The punching pin is mainly used for precision molds. It requires 222 pieces one time for the molds. The other is hard alloy punch head, which is used in 200 pieces, which requires good product consistency. The customer said that the previous pins and punching heads provided by other suppliers have poor consistency and need to be finely modified. The consistency of the precision tungsten steel punches produced by our company is very good, and the surface finish of the products is 0.2. The dimensional tolerance requirement can be +0.002, which fully meets the standard. Moreover, the bottom is also subjected to internal chamfering treatment, which fully satisfies the customer's direct installation and operation. The consistency of the tungsten carbide punch needles produced by our company is according to the customer's drawings, which maximizes the customer's mold service life.

Advantages:

Carbide punching pin is a part of cemented carbide mold, also called hard alloy punching pin or carbide punching pin. It is mainly used for punching hardware parts or electronic parts. Of course, other non-metal parts can also be punched out, even belt holes, plastic holes, etc. can be punched. Because of its characteristics of acid-resistant, rust-free and long service life, it has wide application. The pharmaceutical industry has selected the punch for stamping tablets. The punches and punching pins used for precision molds require good consistency and coherence, so that the manufactured products can meet dimensional accuracy. Especially for the mass production of precision tungsten steel punch, the consistency control must be controlled from the blank material production to the precession processing. Each processing procedure must be strictly controlled! Our technical staff strictly controls every step of the finishing process to ensure that each punching punch is qualified.