Introductions:

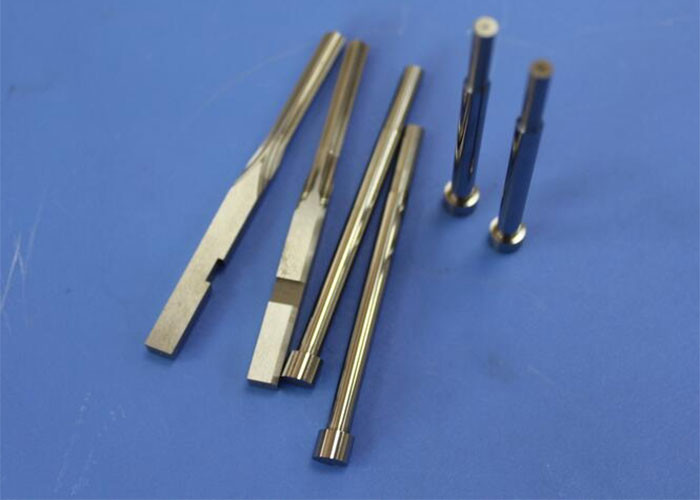

Carbide punching pin, also known as tungsten steel punching needle, is fine grinded of hard alloy round bar. It has the properties of high precision, high hardness and good bending strength, suitable for hardware and electrical processing industry. It is generally used for punching on stamping dies to separate or plastically deform the material to obtain the required parts. Due to its characteristics of high hardness, long service life, corrosion resistance and no rust, it is widely used in industrial machinery manufacturing and processing.

The punching pin is one of the precision mold parts, and is used to enhance the strength of the thimble and prevent the thimble from being deformed or broken. As one of the important connector mold parts, the punching pin has great influence on the normal operation of the mold. So, the punching pin processing requirements are high. When the punching pin is plastically denatured in the mold cavity, it flows and slides along the surface of the cavity, causing severe friction between the surface of the cavity and the punching pin. Thus, the friction causes the punching needle to fail due to wear. Therefore, the wear resistance of the material is one of the most basic properties of the pin. Hardness is a major factor affecting wear resistance. In general, the higher the hardness of the punch pin, the smaller the wear and the better the wear resistance. In addition, the wear resistance is also related to the type, quantity, shape, size and distribution of carbides in the material.

The hard alloy punching pins produced by our company have been widely used in industrial production and have received wide recognition. Our hard alloy punching pins have a lot of advantages, such as high hardness, high strength and good wear resistance.

Technical parameters:

Our company provides customized hard alloy punching pins according to the customer's drawing requirements, and provides the actual physical parameters as follows:

1. CO content: 10% ~ 12%

2. Density (g/cm³): 14.0 ~ 14.5

3. Hardness: 89 ~ 92.0 HRA

4. Grain size: 0.6 ~ 1.2 um

5. Bending strength: 4000MPa

6. Modulus of elasticity (GPa): 490.

7. Thermal expansion coefficient 10-6/0C: 5.4.

8. Tungsten steel punch size specifications are customized according to the drawings.

Advantages:

Carbide punching pin is a part of cemented carbide mold, also called hard alloy punching pin or carbide punching pin. It is mainly used for punching hardware parts or electronic parts. Of course, other non-metal parts can also be punched out, even belt holes, plastic holes, etc. can be punched. Because of its characteristics of acid-resistant, rust-free and long service life, it has wide application. The pharmaceutical industry has selected the punch for stamping tablets. The punches and punching pins used for precision molds require good consistency and coherence, so that the manufactured products can meet dimensional accuracy. Especially for the mass production of precision tungsten steel punch, the consistency control must be controlled from the blank material production to the precession processing. Each processing procedure must be strictly controlled! Our technical staff strictly controls every step of the finishing process to ensure that each punching punch is qualified.