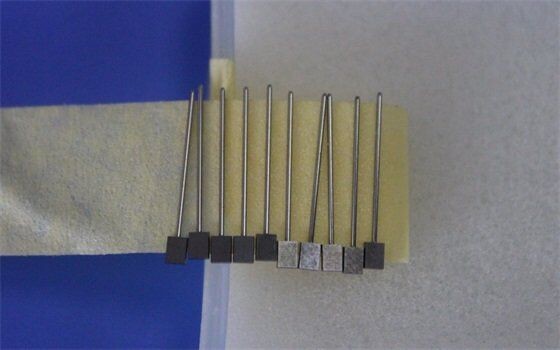

Cemented Alloy Punch Head Tipped Tools Tungsten Carbide Bits

Nowadays we've got a huge order from a trading company, that is 500,000 pcs of this OEM made cemented alloy punch head.

It's tungsten carbide bits made for hard metal tipped tools, well suitable for brazing, drilling, punching and various hard metal industry applications.

Introduction:

Tungsten steel punch head, carbide bits, can be made according to different demands for batch hole processing, especially in the complete production of the mold.

The stamping mold is designed according to various processing materials. They basically complete the product operation or semi-finished product through multi-step punching processing.

The different shapes and specifications of tungsten carbide punch needle required by different steps, which involves the heterogeneous punch machining and production of supporting stamping mold.

Sanxin Tungsten Carbide Manufacture, an expert who've been specialized in Carbide bits, blades, and OEM parts industry for 20 years.

| 1, | National high-tech enterprise certification |

| 2, | Processing High tolerance accuracy ±0.002mm |

| 3, | Wear-resistant, heat-resistant and anti-corrosion |

Tungsten carbid grade: K20, K10, K30 or other appointed high quality carbid grade

Advantages:

Cemented carbide wearing parts, also called wolfram carbide (WC) parts, are a commonly used high-end punch head carbide bits in the machinery industry, because of its high hardness, good toughness, superior high and low temperature wear resistance, small adhesion, good corrosion resistance, high thermal conductivity, less friction coefficient, and acid and alkali corrosion resistance does not rust, easy maintenance and other characteristics.

With its good toughness, high temperature resistance and high wear resistance, the service life is 10~50 times longer than the general metal parts.