-

Home

-

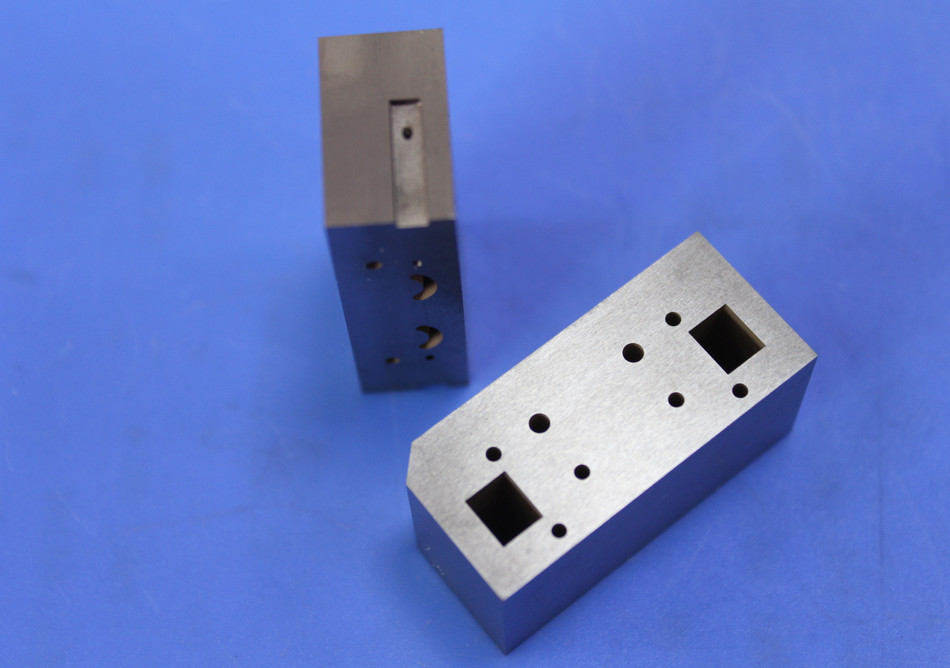

Carbide Tools

- Punch Mold Components

- Carbide Boring Tools

- PCD Turning Inserts

- Carbide Turning Inserts

- Carbide Grooving Insert

- Carbide Threading Inserts

- Carbide Milling Inserts

- Solid Carbide Saw Blades

- Carbide End Milling Cutters

- Carbide Drilling Tools

- CNC Tool Holder

- Carbide Cutting Inserts

- Tungsten Carbide Material

- Cut Off Inserts

-

Cemented Carbide

-

News

-

About Us

-

Get A Free Quote