Introduction:

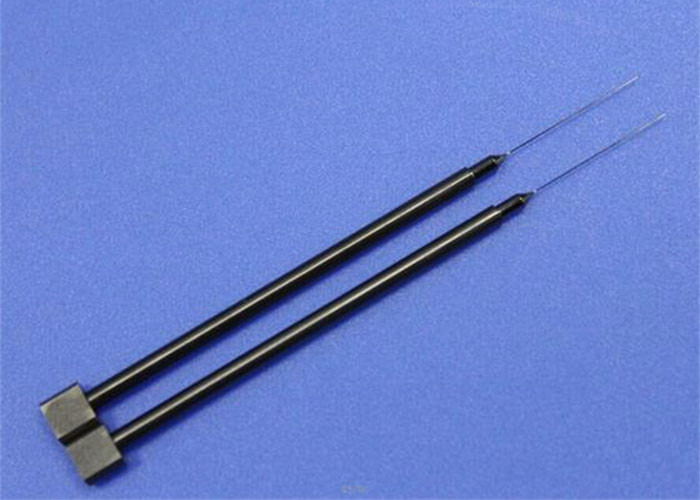

Stator iron core punch needle, in other words punch head production and processing, stator iron core punch die supporting the production of the use of the related tungsten carbide punch.

With its own excellent performance of the carbide material, as the core component of the stamping die operation, the tungsten carbide punch is installed on the stamping die for continuous stamping and punching operation, so that the processed materials have separation or plastic deformation, so as to obtain the required finished products or semi-finished products.

In the cold stamping processing, process the material into parts via a pressure processing method that applies pressure to materials to produce separation or plastic deformation to obtain the required parts at room temperature, which is more common in industrial production.

Punching die is an essential process equipment for stamping production and a technology-intensive product.

The quality, production efficiency and production cost of the stamping parts are directly related to the mold design and the precision and quality of the mold accessories.

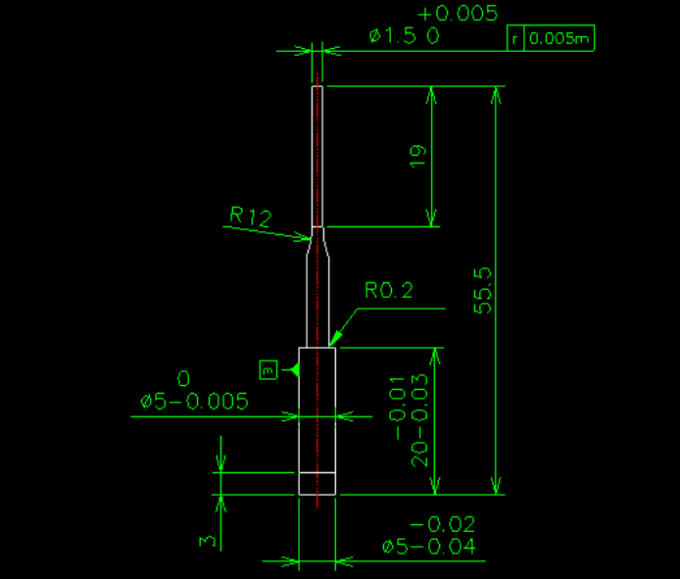

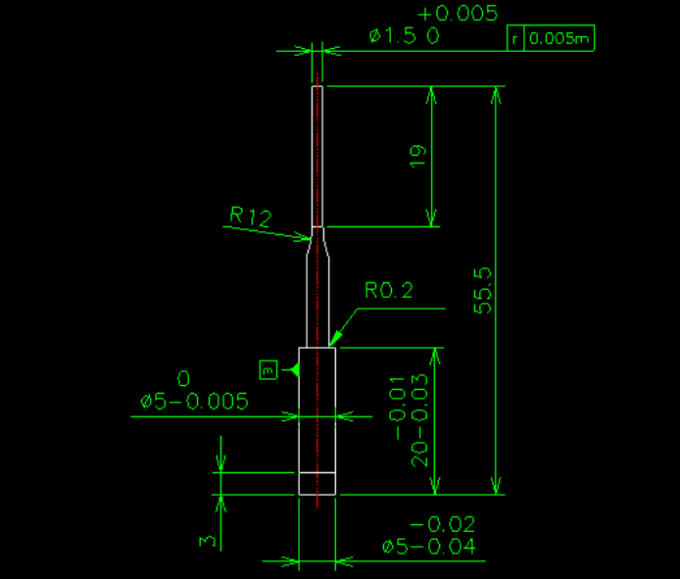

Technical drawing:

If the customer has special requirements, we can provide tungsten steel products for production and processing according to the specific situation.