Introduction:

We can provide a variety of hard alloy (tungsten steel) molds, can be customized according to drawings or samples to meet your needs.

Carbide (tungsten steel) progressive punching die

The unique production process effectively controls the internal stress of the large-size mold material and avoids the cracking during cutting process.

The unique alloy composition enhances the corrosion resistance of the alloy during electrical processing and improves the performance and service life of the mold.

Carbide (tungsten steel) cold heading dies

The scientific treatment improves the strength and toughness of the cemented carbide and increases fatigue strength and impact resistance.

Cemented carbide (tungsten steel) powder metallurgy pressing die

It is an ideal material for forming molding such as magnetic powder, ceramic powder, refractory metal powder and iron-copper-based powder. It is fully dense, highly wear-resistant and corrosion-resistant.

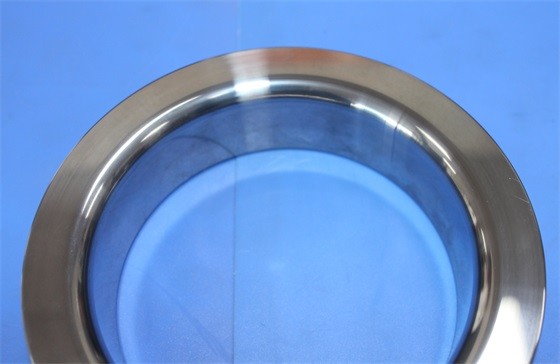

Carbide (tungsten steel) drawing die

Excellent performance, stable quality and cost-effective. It is a good choice for carbide mold materials.