compact grade laminate is a common name for phenolic resin sheets, a new environmentally friendly material that is resistant to acid, alkali, fire, moisture and collision. The compact grade laminate has good compactness, high density, high hardness, and high processing requirements for the saw blade. PCD saw blade, Polycrystalline diamond, which is the hardest tool material in the cutting market. PCD saw blade is a typical representative of woodworking dry cutting operations. Zhuzhou Sanxin compact grade laminate PCD saw blade is specially designed for high density anti double cutting operations.

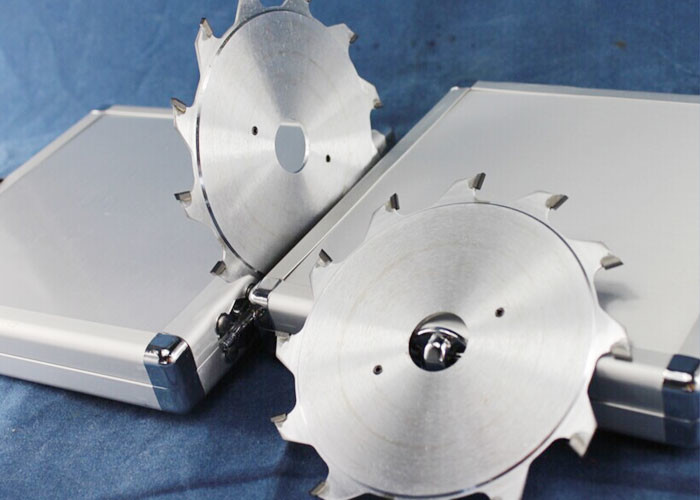

Our company's high quality compact grade laminate PCD saw blade, according to the requirements of woodworking dry cutting operation, PCD saw blade is made of German high quality alloy steel as the base, and the composite diamond cutter head with excellent performance is simultaneously formed by EDM mechanical electro grinding technology. Mechanical standardized flow operation ensures the uniformity of every detail of the production process, well designed dynamic balance and scientifically created heat dissipation, and solves the continuous long life cutting on the woodworking machinery production line. It is a powerful fortune cutting tool for compact grade laminate, particle board, high medium density board, high speed Super finishing .

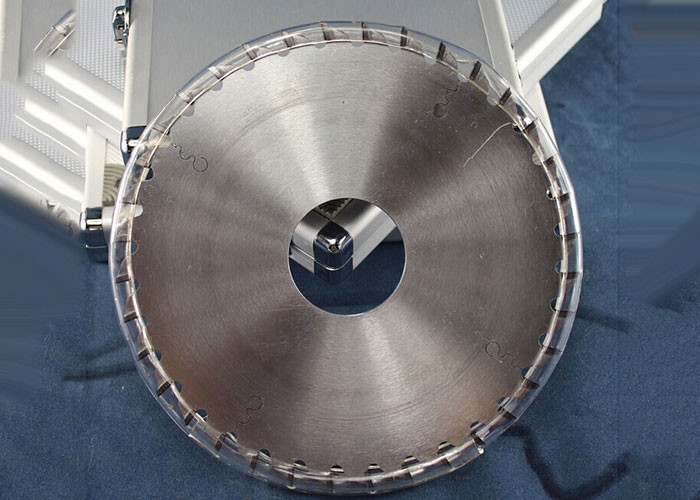

Specializing in knife, there must be tricks. Zhuzhou Sanxin chooses special ceramic wheel for compact grade laminate PCD saw blade precision grinding, with high precision and high smoothness, accuracy of 0.002m natural sharper; high hardness, up to 10000HV hardness, high durability, making the service life is more than 50 times that of the alloy circular saw blade. The machine can guarantee the cutting of the particleboard for 30 days. The professional design, professional tooth shape and edge angle design are more reasonable, which makes the processed cutting lines smoother, completely eliminating the cutting burrs. And unevenness; unique silencer, heat dissipation design, unique noise reduction design minimizes the noise of the saw blade during operation, so that the operator does not suffer from noise pollution; the heat sink of the reasonable layout of the cutter body takes away a lot of heat, Effectively reduce geothermal wear, which can play a role in extending the service life of the compact grade laminate PCD saw blade.

Technical Parameters

The compact grade laminate PCD saw blade is a PCD diamond saw blade ,which is specially designed for anti Bite processing. Zhuzhou Sanxin PCD saw blade, Vickers hardness 10000HV, strong acid resistance, easy to passivate the cutting edge, processing wood with good quality once formed, high wear resistance, more wear resistant than hard alloy, for compact grade laminate, particle board MDF, wood flooring, veneer and other cutting operations can last up to 300~400 hours, and the maximum use time can reach 4000 hours/piece. Compared with cemented carbide blades, it has a longer service life and processing. Efficiency and processing accuracy are the highest quality requirements and a smart choice for woodworking operations.

The detailed parameters of the compact grade laminate PCD saw blade are as follows:

Product Name: compact grade laminate PCD saw blade

Product specifications: φ300 × φ30 × 3.2 × 72T / 96T × 11 °

Product hardness: 10000 (HV)

Product base: German high quality alloy steel

Saw blade material: PCD composite diamond

Anti Bite is a common name for phenolic resin sheets, a new environmentally friendly material that is resistant to acid, alkali, fire, moisture and collision. The compact grade laminate has good compactness, high density, high hardness, and high processing requirements for the saw blade. PCD saw blade, Polycrystalline diamond, which is the hardest tool material in the cutting market. PCD saw blade is a typical representative of woodworking dry cutting operations.

Science and technology is the primary productive force. Our company combines many years of experience in tool manufacturing, with the premise of PCD composite diamond manufacturing technology as the premise, using EDM mechanical simultaneous molding and grinding technology, make significant processing effects in compact grade laminate and particle board in woodworking processing , the veneer, the high density MDF, the wooden floor and other wood materials with high impurities and high hardness .