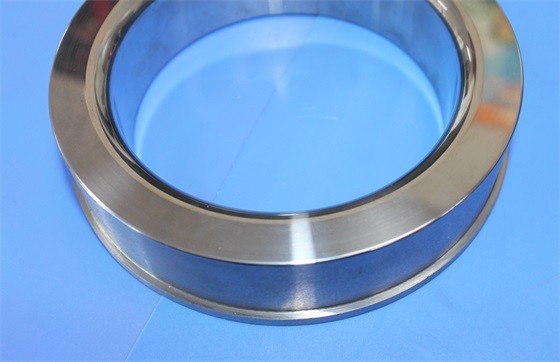

Cemented Tungsten Carbide Wire Drawing Dies Double Hole Insert Head

Introduction:

The cemented carbide for drawing die is carbide with low cobalt content. The main raw material is 99.95% tungsten carbide and a small amount of cobalt---named tungsten-cobalt alloy. Carbide wire drawing die has good wear resistance, impact resistance, polishing and corrosion resistance, easy to repair, and low price. It is commonly used as wire drawing core material, widely used for the rough and medium drawing die. By improving the composition and structure of the cemented carbide, controlling the fluctuation of the carbon content, and refining the particles of the carbide, thus can improve the performance of the material and prolong the service life.

Advantages:

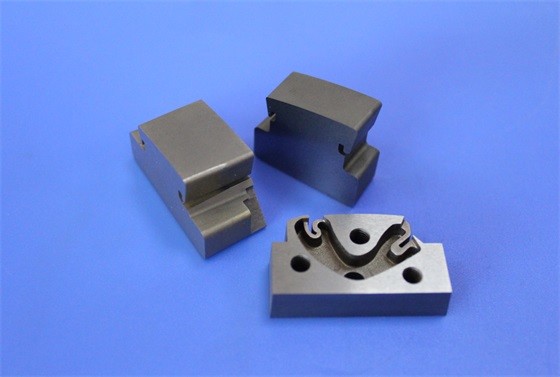

As the industrial tooth, cemented carbide is an effective wear-resistant tool in the manufacturing industry. As a cemented carbide processing and production manufacturer, relying on the cemented carbide production technology and complete industry chain in Zhuzhou, we provide hard alloy mold parts and tungsten carbide large-sized cavities for customers, also can provide non-standard shaped carbide wear-resistant parts. Based on customer's drawing requirements, we use high-quality materials to satisfy customers' demands. Especially, high-precision fine-grained mold products are our processing strengths. From raw material selection to finished carbide mold parts, we strictly control every process of production.

| Name: | Carbide Wire Drawing Dies | Pin Ceramic Nozzle: | Cemented Tungsten |

|---|

| Tungsten Steel Slider Insert Head: | Costum | Type: | Carbide (tungsten Steel) Mold |

|---|

| Model: | Carbide Wire Drawing Die | Tungsten Steel Pin: | Double-hole Insert Head |

|---|