Woodworking PCD saw blade, specializing in wood production and cutting, especially for high density sheet cutting of particle board, MDF, veneer, pit special board, is the products of Zhuzhou Sanxin Cemented Carbide Production Co., Ltd.

As a manufacturer of Zhuzhou cemented carbide tools, our company has been manufacturing in high performance cutting tools for machining and cutting operations. Science and technology , as the primary productivity , is the biggest driving force for innovative technologies and new products. The application of PCD diamond as a superhard tool material has always been a high quality performance of science and technology. Due to the high manufacturing cost, high hardness, high wear resistance, high processing difficulty, high manufacturing threshold and high price, it’s difficult for PCD saw blades to popularize woodworking machining cutting operations. Our company's woodworking PCD saw blade for large woodworking furniture cutting operations has become the latest product. The project has carried out various research, development and experiments, showing excellent cutting performance.

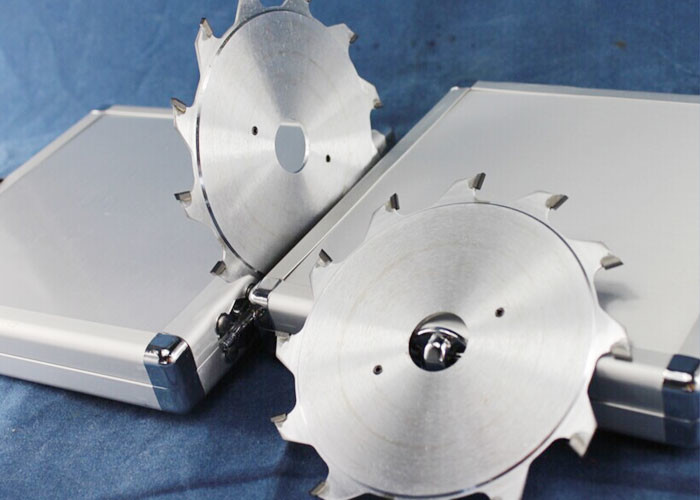

As a typical representative of superhard tools, woodworking PCD saw blades lead the woodworking dry cutting operations. It’s essential for Woodworking machinery cutting operations To improve production efficiency and production quality by using high quality PCD saw blades. The PCD saw blade produced by our company is made of German high quality alloy steel. The composite diamond cutter head with excellent performance is simultaneously formed by EDM mechanical electro grinding technology. The whole process is standardized and flow through, ensuring the uniformity of every detail of the production process. The well designed dynamic balance and scientifically created heat dissipation solve the continuous long life cutting of woodworking machinery production line. It is a powerful wealth cutting tool for particleboard, high medium density board and high speed super finishing. Excellent performance as the basis, on site experimental testing standards, can be used continuously for 300-400 hours; strong wear resistance can be repeatedly honed, configured in precision electronic saws, push table saws, the maximum use time can reach 4000 hours / piece . This provides a strong product technical support for woodworking operations, eliminating many troubles in replacing the tool and minimizing the production cost of the enterprise.

Durable and Wear resistant, it is the advantage of woodworking PCD saw blade ,different from carbide saw blade. The actual customer test results of Zhuzhou Sanxin PCD saw blade surpass 40-50 pieces of carbide saw blade, which provides strong product and service support for the long term continuous operation of woodworking dry cutting. For woodworking cutting operations, cross cutting, longitudinal sawing, sawing of wooden composites, sawing of non ferrous metals, sawing of metal, sawing of picture frames, sawing of plexiglass, sawing of hard plastics, sawing of veneers, veneers Grooving, wooden composite grooving is a performance of high quality cutting performance. For cork, hardwood, MDF, non ferrous metals, square tubes, plywood, profiles, single veneers, veneer veneers, aluminum, angle iron, double veneers, picture frames, plastics, round tubes, particle boards, plexiglass, etc, the Cutting operation performed well.

Woodworking PCD saw blade, also called woodworking diamond drama, woodworking PCD saw blade Vickers hardness 10000HV, strong acid acid resistance, is a typical representative of superhard tools, one of the hardest tools!

Woodworking PCD saw blade, the cutting edge is not easy to passivate, the processed wood has good molding quality, high wear resistance, and is more wear resistant than hard alloy. It can be used for cutting machine, MDF, wood floor, veneer and other cutting operations. Up to 300~400 hours, the maximum using time can reach 4000 hours/piece. Compared with cemented carbide inserts, the service life is longer, and the processing efficiency and processing precision are the highest quality requirements. Smart choice.

Zhuzhou Sanxin Woodworking PCD saw blade, specializing in large scale wood cutting operations, suitable for precision sliding table saws, electronic saws, cross cut saws, commonly used woodworking PCD saw blade specifications are:

Product parameters: PCD saw blade

Product Name: PCD Diamond Saw Blade

Product Specifications: φ300×φ30×3.2×96T/72×11°

Product hardness: 10000 (HV)

Product base: Germany high quality alloy steel

Saw blade material: PCD composite diamond

Product wear resistance: 50-150 times

Continuous operation time: 300-400 hours

If you want to do something good, you must first sharpen your tools! The woodworking PCD saw blade produced by our company is made of German high quality alloy steel. The composite diamond cutter head with excellent performance is simultaneously formed by EDM mechanical electro grinding technology. The whole process is mechanically standardized and the flow is guaranteed to ensure the consistency of every detail of the production process. The well designed dynamic balance and scientifically created heat dissipation solve the continuous long life cutting of woodworking machinery production line. It is a powerful wealth cutting tool for particleboard, high medium density board and high speed super finishing.

Specializing in knife, there must be tricks. As a professional manufacturer of Zhuzhou cemented carbide inserts, we have been committed to providing high quality cutting tools for industrial production cutting. Science and technology ,as the primary productivity, is a good performance of innovative operations. Taking woodworking machinery cutting operations as an example, the excellent performance of PCD saw blades is suitable for vertical cross section single and double veneers, multi layer boards, particle boards, etc., and is arranged in precision electronic saws and push table saws.

Service is fundamental, based on quality, focus on brand, customers’ satisfaction is the best value we pursue. Our company specializes in the production of woodworking PCD diamond saw blades with German high quality alloy steel as the base. The welding high performance PCD composite diamond cutter head is exquisitely formed, and the whole process is mechanically standardized. It ensures the uniformity of every detail of the production process and the well designed dynamic balance. And the heat dissipation made by science that ensures the PCD composite diamond saw blade is consistent with the service life of the woodworking cutting operation and the cutting operation. It can be used for more than 300-400 hours continuously, and can be used for multiple times to ensure the best service life. The maximum using time is 4,000 hours/piece, and the company provides powerful product technical support for woodworking furniture cutting operations to maximize production efficiency and reduce production costs.