Zhuzhou sanxing Cemented Carbide Co., Ltd. manufactures and direct sales super hard diamond woodworking saw blades. It is mainly suitable for cutting work of veneer, melamine board, ecological board, compact grade laminate and other wood board materials.

The veneer comprises a plate body, wherein the plate body is a layered structure, comprising a pattern layer, a bottom paper layer and a decorative layer; and a decorative layer is arranged between the pattern layer and the bottom paper layer. The pattern layer, the decorative layer, and the bottom paper layer are press-bonded as a whole. Moreover, the panel of the veneer is too rigid and requires a wear-resistant saw blade with a long service life to cut it.

As a cemented carbide producer, when a carbide saw blade is used to cut a sheet material, it requires a large number of sharpenings. It must be ground every 3 to 5 hours, thus its service life will be shortened.

Therefore, our company specializes in the manufacture of high wear-resistant panel PCD saw blade for the characteristics of the veneer. It is durable and can be used continuously for 300-400 hours. It has high wear resistance, high hardness, sharp edge and other characteristics, and it has long service life. In contrast, cemented carbide saw blades are relatively more expensive to use than PCD blades.

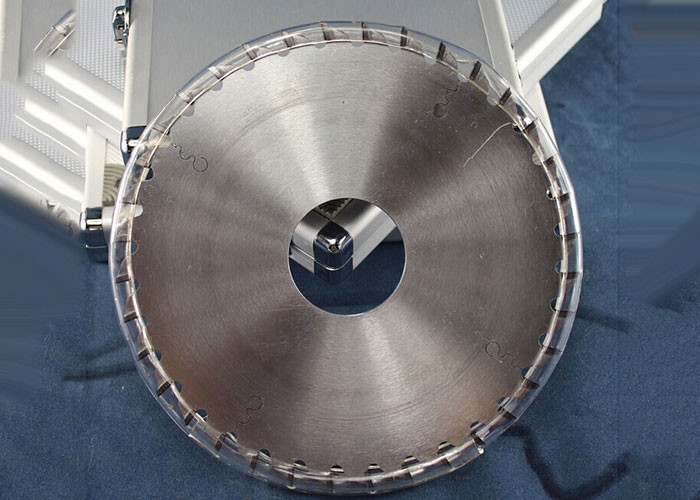

Our company specializes in manufacturing high-wearing veneers PCD saw blades, namely super-hard diamond woodworking saw blades. Its main specifications are φ300×φ30×3.2×96T×11°, the abradability is 50-150 times. It has a Vickers hardness of 10000 HV, strong acid resistance, and the cutting edge is not easy to be passivated. The wood processed by it is of good quality in a single molding.

We select German high-quality alloy steel as the base body and weld it with high quality PCD composite diamond cutter head. Good dynamic balance and scientific heat dissipation design combines the the composite diamond cutter head with excellent performance to produce PCD saw blade by EDM mechanical electrogrinding technology.The whole process of mechanical standardization flow operation ensures the consistency of every detail of the production process.

At present, the high quality carbide circular saw blade must be removed and grind every half a day or every day. Due to the frequent change of blade every day, the productivity is seriously affected, and the cost of the saw blade is greatly increased, which also reduces the product processing quality.Composite PCD saw blades last 50 times longer than carbide saw blades.

A PCD super hard saw blade is better than 50 carbide circular saws. PCD has strong acid resistance, and its edge is not easy to be passivated. The quality of the processed wood is high. It reduces the time for tool change and sharpening, reduces production costs, and improves processing quality and efficiency.

After sales service

As a manufacturer of professional cutting tools, we produce and process superhard diamond woodworking saw blades for woodworking cutting operations.

Service is fundamental, based on quality, focus on brand, customer satisfaction is the best value we pursue. The PCD woodworking saw blades manufactured by our company are made of German high-quality alloy steel. Welded high performance PCD composite diamond cutter head is delicately formed. The whole process of mechanical standardization flow operation ensures the consistency of every detail of the production process, the carefully designed dynamic balance and the scientifically created heat dissipation, ensuring the consistency of the PCD composite diamond saw blade for the service life of the woodworking cutting operation and the cutting operation. It can be used continuously for more than 300-400 hours, and can be used for multiple times to ensure the longest service life. The maximum service time is 4000 hours/piece;we strive to provide strong product technical support for woodworking furniture cutting operations to maximize production efficiency and reduce production costs.