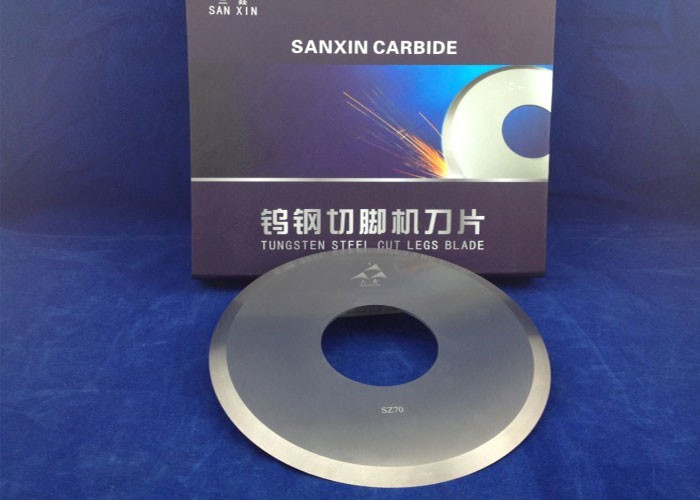

Product description

Lathe processing cemented carbide (tungsten steel) blade is applied to processing small spare parts, especially stainless steel ones. Our blade has remarkable performance.

Based on quality, focus on brand. Zhuzhou Sanxing lathe processing cemented carbide blade is for small spare parts’ process. Beside possessing the following qualities---various product specifications, variable product models, targeted product application, our blade also maximally meets automatic lathe machines’ requirements for small spare parts, especially for tough ones like ss316, ss304. Our lathe processing cemented carbide blade’s remarkable performance is comparable to the international level.

Major Product Series:

- Front sweep cemented carbide blade: with grinding chip removal groove; for processing general steel; for stainless steel with chip removing difficulties.

- Back sweep cemented carbide blade: minimum tip protrusion; achieving high precision process machining with screw fixing method.

- Cutting cemented carbide blade: achieving high precision process with its fine sharpness and grinding chip removal groove.

- Slotted cemented carbide blade: its sharp front corner of chip groove is more likely to prevent the burrs in groove and therefore brings a perfect process.

- Thread cemented carbide blade: its sharp and independent edge thoroughly eliminates the burrs, thus its service life is prolonged.

Let’s take processing spare parts as an example, whose OD is less than φ7mm. Our ultrafine cemented carbide composite coated blade is of incomparable sharpness. The point of our blade has gone through grinding, therefore it is more precise and acuter. Our blade is high-grader, more durable, more convenient in processing cutting materials like steel, stainless steel, aluminum, brass, resin,etc.

Technical parameters

Lathe processing cemented carbide (tungsten steel) blade has variable product specifications: front wheel cemented carbide blade, boring cemented carbide blade, cutting cemented carbide blade, back turning cemented carbide blade, slotted cemented carbide blade, thread turning cemented carbide blade. If you want to know more specific information including blade’s shape, model, size, material, coating etc. you can contact our customer service staff.

Configuration advantages

Zhuzhou sanxing Cemented Carbide Co., Ltd., based on Zhuzhou 60 years’ cemented carbide military production technology, provides high quality cemented carbide blade for automatic lathe’s small spare parts processing. Our cemented carbide blade for small spare parts has many different series. With its unique groove design and coating technique, our blade has become the first choice for stainless steel processing, especially for tough ones like ss316, ss304, etc. Our blade has unparalleled sharpness, making small spare parts processing more convenient and faster.

Post-sale service

Zhuzhou Sanxing lathe processing cemented carbide blade, with high quality, good service, competitive price to meet our customer’s needs. We will try our best to maximize customer productivity and our competitiveness. Quality assurance is our company's bounden duty --- product quality being fine and stable, service quality being fast and on time, operating quality being creating customer value. Our quality control is based on ISO9001 quality system, using advanced testing technology and equipment as a means. Our company is people-oriented, so that quality control runs through every link of enterprise operation.