Introduction:

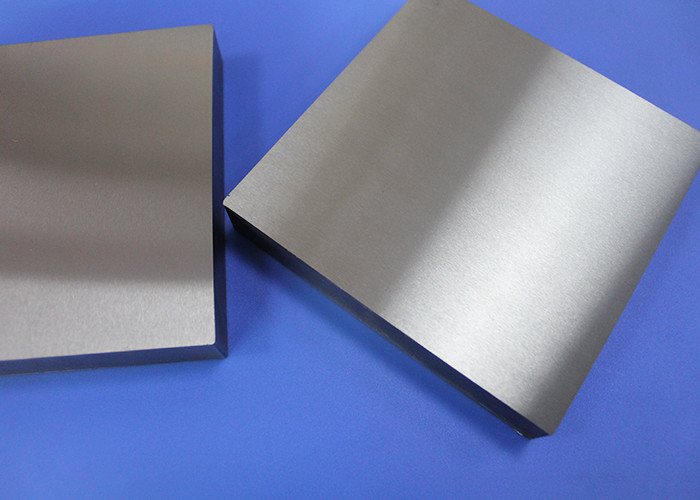

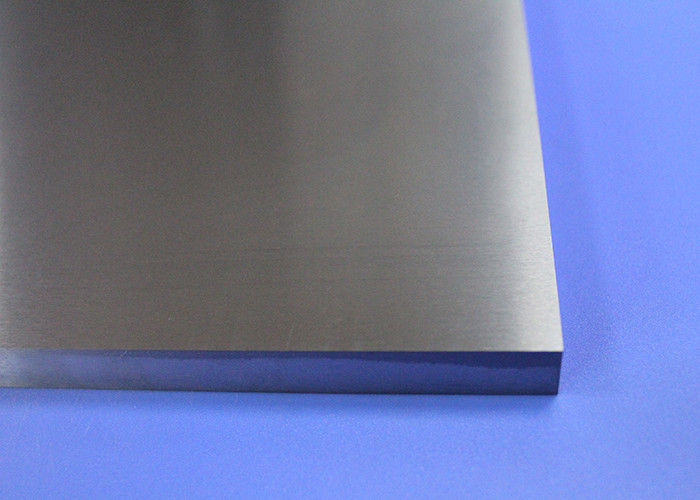

Our company uses high-quality ultra-fine tungsten carbide powder as raw material, and adopts advanced preparation technology to mass produce ultra-fine crystal hard alloy sheet. It has high strength and high hardness, is the first-choice materials for mechanical processing and mold production. It is widely used in various production and processing fields, can be customized according to your specifications to meet your needs.

The concept of cemented carbide: A composite material consisting of refractory metal compound (hard phase) and binder metal (bonded phase) produced by powder metallurgy.

Basic characteristics of cemented carbide:

1. High hardness and high wear resistance

2. High modulus of elasticity

3. High compressive strength

4. Good chemical stability (acid and alkali resistance, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient, thermal conductivity, electrical conductivity and similar to iron and its alloys

Application of cemented carbide: modern tool materials, wear resistant materials, high temperature and corrosion resistant materials.

Technical parameters:

Steel sheet

| Grade | Co% | WC% | Hardness HAR | Density g/cm³ | Bending strength MPa | Characteristics and application |

| SX01 | 12 | 88 | 89.2 | 14.29 | 3500 | With exclusive formulation of selected WC raw materials and imported cobalt powder of HIP follow-up treatment, mainly suitable for producing high-speed die and multi-station progressive die. |

| SX02 | 11.8 | 88.2 | 88.2 | 14.3 | 3300 |

| SX03 | 14 | 86 | 87.1 | 14.1 | 3200 | suitable for producing punching molds for processing hardware and standard parts. |

| SX04 | 15 | 85 | 86.5 | 13.9 | 3200 |

Material specification and dimension tolerance

| Blank specification:mm (L×W×T) | Tolerance |

| Blank | Finish blank |

| Length: mm | Width: mm | Thickness: mm |

| 100×100×5.0 | ±2.2 | ±2.2 | ±0.35 | ±0.01 |

| 100×100×5.5 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×6.0 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×6.5 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×7.0 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×7.5 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×8.0 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×8.5 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×9.0 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×9.5 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×10 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×11 | ±2.2 | ±2.2 | ±0.45 | ±0.01 |

| 100×100×12 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×13 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×14 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×15 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×16 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×17 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×18 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×19 | ±2.2 | ±2.2 | ±0.6 | ±0.01 |

| 100×100×20 | ±2.2 | ±2.2 | ±0.7 | ±0.01 |

| 100×100×22 | ±2.2 | ±2.2 | ±0.7 | ±0.01 |

| 100×100×24 | ±2.2 | ±2.2 | ±0.7 | ±0.01 |

| 100×100×26 | ±2.2 | ±2.2 | ±0.9 | ±0.01 |

| 100×100×28 | ±2.2 | ±2.2 | ±0.9 | ±0.01 |

| 100×100×30 | ±2.2 | ±2.2 | ±0.9 | ±0.01 |

| 100×100×32 | ±2.2 | ±2.2 | ±0.9 | ±0.01 |

| 100×100×34 | ±2.2 | ±2.2 | ±0.9 | ±0.01 |

| 100×100×36 | ±2.2 | ±2.2 | ±1.1 | ±0.01 |

| 100×100×38 | ±2.2 | ±2.2 | ±1.1 | ±0.01 |

| 100×100×40 | ±2.2 | ±2.2 | ±1.1 | ±0.01 |

| 100×100×45 | ±2.2 | ±2.2 | ±1.1 | ±0.01 |

| 100×100×50 | ±2.2 | ±2.2 | ±1.3 | ±0.01 |

| 100×100×55 | ±2.2 | ±2.2 | ±1.3 | ±0.01 |

| 100×100×60 | ±2.2 | ±2.2 | ±1.5 | ±0.01 |

| 100×100×70 | ±2.2 | ±2.2 | ±1.5 | ±0.01 |

| 100×100× | ±2.2 | ±2.2 | ±1.5 | ±0.01 |

Advantages:

The concept of cemented carbide: A composite material consisting of refractory metal compound (hard phase) and binder metal (bonded phase) produced by powder metallurgy.

Basic characteristics of cemented carbide:

1. High hardness and high wear resistance

2. High modulus of elasticity

3. High compressive strength

4. Good chemical stability (acid and alkali resistance, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient, thermal conductivity, electrical conductivity and similar to iron and its alloys

Application of cemented carbide: modern tool materials, wear resistant materials, high temperature and corrosion resistant materials.