Introduction:

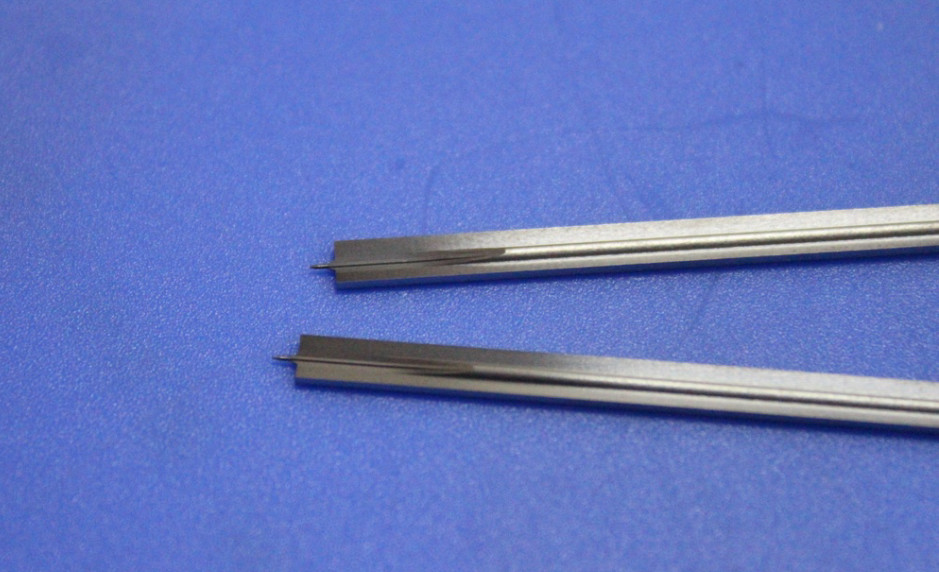

The toothed carbide grinding machine strip is mainly used for feed crushing operations. The cutting demands of cemented carbide products can achieve the requirements of long-term continuous work and long service life.

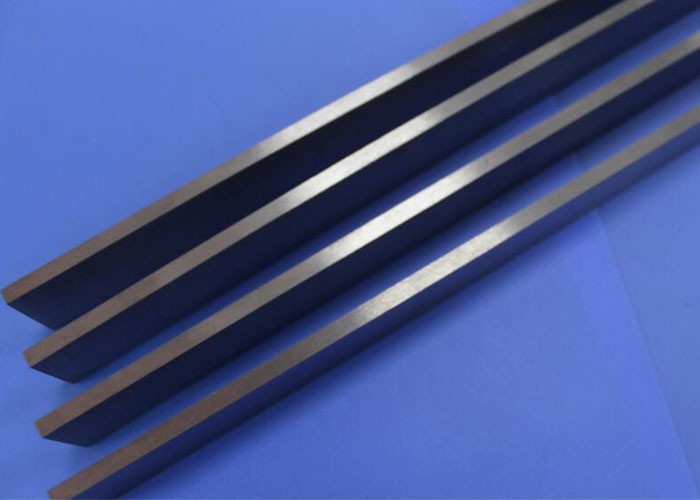

Carbide strip is a type of hard alloy products, which are named for their long square strip shape, that is one of many carbide shaped nouns. The cemented carbide strip is mainly composed by tungsten carbide and cobalt, referred to as tungsten-cobalt alloy, and is made by powder metallurgy method. With high flexural strength and high hardness, it is suitable to produce high-quality carbide tools. It has excellent cutting performance, with long-term operation and long service life when used in feed mill machinery.

Technical parameters:

The hard alloy toothed strip for grinding is customized according to the requirements of the feed crushing machine, and is an essential cutting tool for feed crushing machine operation

Advantages:

The hard alloy strip has the characteristics of high hardness, good weldability, high hardness and high wear resistance. It is mainly used for manufacturing solid wood, MDF, gray cast iron, non-ferrous metal materials, chilled cast iron, hardened steel, PCB and brake materials, also commonly used as cutting tools. When using, we should choose the appropriate material of the hard alloy strip according to the application purpose. relying on the complete cemented carbide industrial chain in Zhuzhou, we can provide customers with various specifications of hard alloy strips.