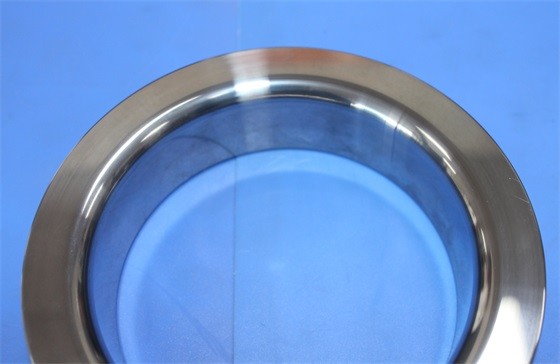

Customized Carbide Mold Carbide Drawing Dies For Drawing Molds Of Steel

Introduction:

The cemented carbide drawing die is one of many cemented carbide molds. The working part of the die is made of hard alloy. The fixed part is made of 45# steel. And then the two are assembled together, which can minimize the material cost and truly save money for customers.

Technical parameters:

Technical parameters of cemented carbide drawing die

| Grade | Density: g/cm³ | Bending strength: TRS | Hardness: HRA or HV | Porosity | Performance and application |

| SXL03 | 14.95~15.11

15.15~15.35 | 1130~1300 | 91.5 | | with good wear resistance, mainly used to make small-sized drawing molds. |

| SXL06 | 14.88~15.04

14.85~15.05

14.0~14.95 | 1530~1550

1580 | 89.5 | 2.0~1.6 | With good wear resistance, used for drawing molds of steel with drawing diameter of 20mm or less, and of carbide, non-ferrous metals and carbide wires or bars under 35mm. |

| SXL08 | 14.65~14.85 14.65~14.85 | 1840~2100 | 89.0 | 2.0~1.6 | With good toughness and wear resistance, used for drawing molds of steel with drawing diameter of 50mm or less, and of carbide, non-ferrous metals and carbide wires or bars under 30mm. |

| SXL30 | 14.29~14.49 | 1910 | HV:1210 | | With excellent strength and toughness, mainly used for drawing molds for workpiece pipes and rods. |

| SXL50 | 13.86~14.06 13.95~14.15 | 2060~2220 | 86.5 | | With excellent strength and toughness, mainly used for drawing molds for workpiece pipes, rods and plates. |

Advantages:

The professional material engineer selects the material grade and superfine particle raw powder according to your requirements.

Advanced precision processing equipment + unique process.

High wear resistance, long service life, greatly reducing the frequency of edge grinding and maintenance.