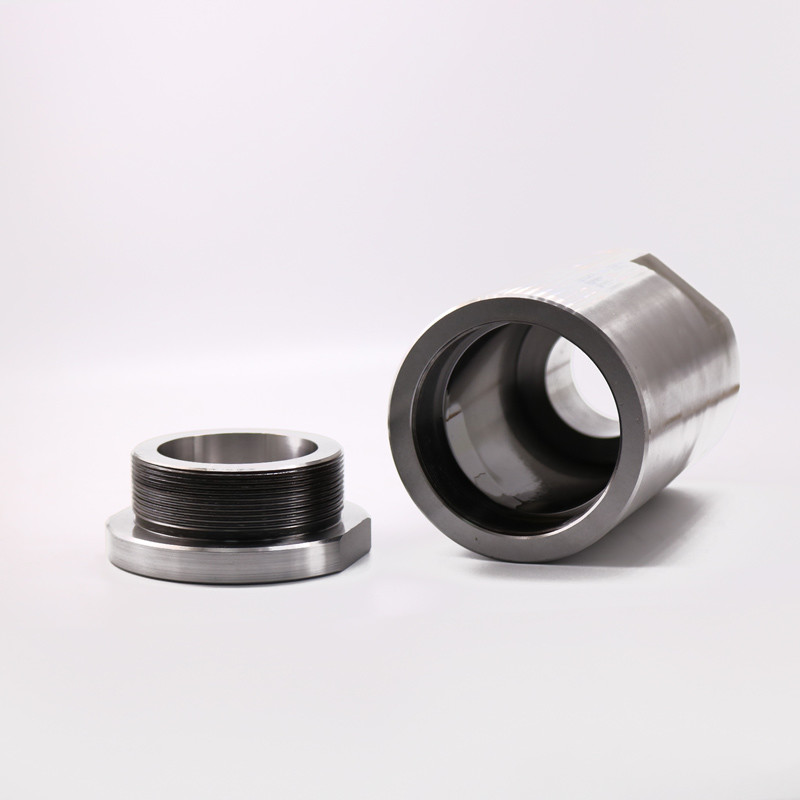

Customized Polished Punch Mold Components Such as Fastening Dies, Punch Pin and NozzleProduct Description:

Fastening Die is commonly used for cold heading and cold punching standard parts, such as bearings, screws and nuts. DORW's proficient team has more than a decade of experience in the fastening sector, as they are well-versed in the characteristics of tungsten carbide and can provide comprehensive solutions, primarily aiming at high-end fastener mould production.

Features:

Carbide

Cemented carbide is a powder metallurgical composite consisting of one more hard material phases (e.g. tungsten carbide) and a binding material (e.g. cobalt). It is an extremely hard material, characterised by high wear resistance an thermal stability. It is used in various fields that require tools or components to be particularly wear-resistant. Compared to die steel, it is more difficult to machine and has a higher material cost, but its service life is often several times longer than that of die steel.

Ceramic

Ceramic materials have good high temperature resistance and play a decisive role in high temperature applications in the continuous operating temperature range of 180 °C to more than 1200 °C. Compared to metallic materials, oxide ceramics are considered to be resistant to chemical attack, especially in acid and alkaline solutions. Common include alumina, zirconia, silicon carbide, silicon nitride ceramics.

High Speed Steel

High speed steel with superior abrasion resistance and toughness for general use.It is mostly used in small batch production or fields with high requirements on material toughness.

Technical Parameters:

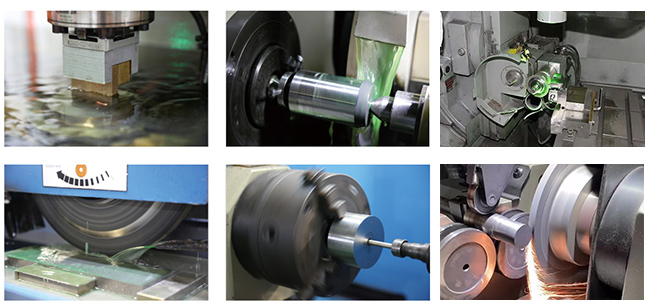

It is essential to involve production technology in order to satisfy our customers' needs. We provides a wide range of services, including cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, middle speed wire cutting, low speed wire cutting, and mirror discharge machining.

These technologies are highly advanced which make our machineries reliable in all kind of production and machining needs. With our state-of-the-art machineries, customers can rest assured of receiving products that meet their requirements.

Applications:

Punch Mold Components with Brand Name Drow

Drow's Punch Mold components, with model number Punch Mold, are made in China and certified with ISO9001. They are available in minimum order quantity of 1 set and the price is negotiable. The packaging details of the product include plastic box or plastic film and the delivery time is 7-14 days. The payment terms are 100% T/T before shipping out the goods. The supply ability of the product depends on the drawing.

The processing technology of Drow's Punch Mold components includes cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, middle speed wire cutting, low speed wire cutting, mirror discharge machining and so on. OEM/ODM service is available with a minimum order quantity of 1 set. The materials used for manufacturing the product are tungsten carbide or HSS and the packaging is done in cartons.

Drow's Punch Mold Components are the perfect choice for punching mold components with the perfect combination of brand name, certification, processing technology, materials, packing and OEM/ODM service.

Customization:

Drow Punch Mold Components Customization Service

Brand Name: Drow

Model Number: Punch Mold

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1set

Price: Negotiable

Packaging Details: Plastic box or Plastic film

Delivery Time: 7~14 days

Payment Terms: 100% T/T before shipping out goods

Supply Ability: Depens on the drawing

Service: OEM/ODM

Shape: Customized

Material: Tungsten Carbide Or HSS

Application: Punch Machine

Size: Customized

We offer a variety of customized services for our Mold Punching Components. Our professional team is experienced in designing and producing high-quality Mold Punching Components according to your specific requirements. Our Mold Punching Components are made of superior quality tungsten carbide or HSS and are tailored to your application. We have a wide range of sizes and shapes available to meet your needs. With our competitive prices and excellent service, our Mold Punching Components are sure to exceed your expectations.

Support and Services:

Punch Mold Components Technical Support and Services

We provide comprehensive technical support and services to ensure the smooth operation of your Punch Mold Components. Our services include:

- Assistance in product selection and application

- Regular maintenance and repair

- Technical advice and troubleshooting

We are committed to providing our customers with professional and efficient services. Our team of experienced engineers and technicians are available to help you with any issues you may encounter.

If you require any assistance with your Punch Mold Components, please contact us.

Support and Services:

Support and Services: