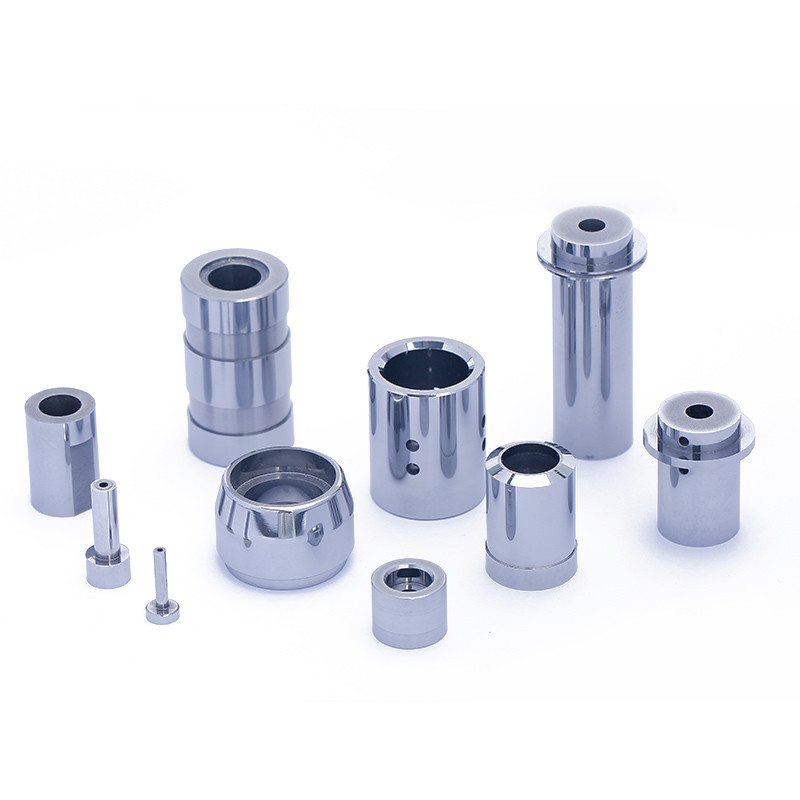

Customized Tungsten Carbide or HSS Punching Mold Components Packaged in CartonsProduct Description:

Fastening Die is typically used for cold heading and cold punching standard parts, such as bearings, screws, and nuts. The team at DORW is professionally experienced with the fastening industry, with over 10 years of in-depth knowledge on the characteristics of tungsten carbide. They are devoted in providing a complete solution with specially emphasized focus on high-end fastener mold production.

Features:

Cemented Carbide:

Cemented carbide is a composite of one or more hard material phases, such as tungsten carbide, and a binder, usually cobalt. This material is extremely hard, denoting superior wear resistance and thermal stability. As a result, it is widely used when the components or tools must withstand particularly tough conditions.

Cemented carbide is more difficult to machine and is higher cost than die steel. Its service life, however, is usually several times longer.

Oxide Ceramics:

Oxide Ceramics feature excellent high temperature resistance. They are typically used in temperature ranges from 180 to over 1200 °C. The best part is that they are highly resistant against chemical attack in acid and alkaline solutions.

Common oxide ceramics include alumina, zirconia, silicon carbide, and silicon nitride.

High Speed Steel:

High speed steel is characterized by superior abrasion resistance and toughness that make it suitable for general use. Although it is mostly used in small batch production or in industries with stringent requirements on material toughness, it still offers good performance in many other applications.

Technical Parameters:

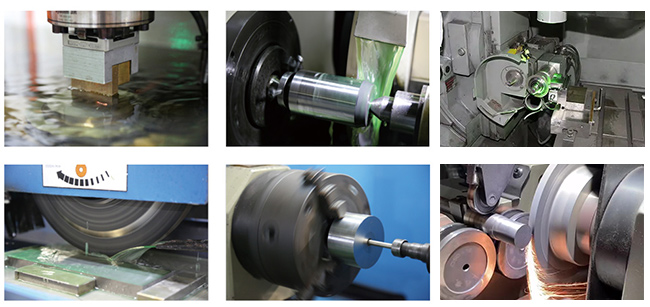

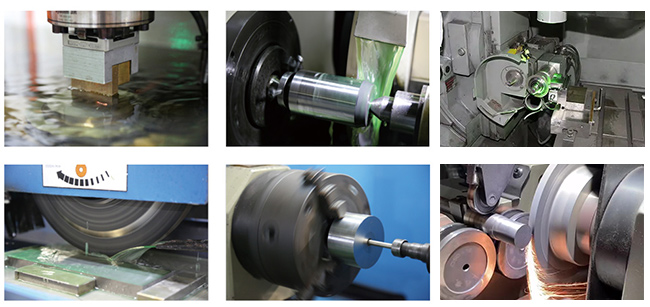

Our production technology covers an extensive range to meet the production needs of our customers. This includes cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, high-speed wire cutting, low-speed wire cutting, and mirror discharge machining.

Cylindrical grinding is a machining process used to improve the surface quality of cylindrical parts. It is mainly used to grind the external surface of circular cylindrical parts. Internal circular grinding is another type of cylindrical machining process. It is used for grinding the internal surfaces of circular objects.

Optical profile grinding is a process of grinding profiles or shapes by controlling the relative movement of the grinding wheel and the profile being machined. Flat grinding is a process of grinding a flat surface. It usually involves a rotating wheel that is coated with an abrasive material.

Thread machining is a process used to cut threads into a material. This process is done with the use of a tool to cut the threads into the material. High-speed wire cutting is a process of using the shear force of high-speed wires to cut metal and other materials. Low-speed wire cutting is a variation of high-speed wire cutting, as it uses wire with slower speed than high-speed wire cutting.

Mirror discharge machining is a process used to improve the surface quality of a part by controlling the discharging current. This current is discharged in such a way that it creates a spark which removes the material from the part, resulting in a better surface finish.

Applications:

Drow Punch Mold Components are widely used in various fields. The brand name is Drow, with model number Punch Mold and place of origin in China. It has been certified with ISO9001, and the minimum order quantity is 1 set. The price is negotiable, and it can be packed in plastic box or plastic film. The delivery time is 7-14 days, and payment terms are 100% T/T before shipping out goods. The supply ability is depending on the drawing, and the size and shape of the product can be customized. The processing technology includes cylindrical grinding, internal circular grinding, optical profile grinding, flat grinding, thread machining, middle speed wire cutting, low speed wire cutting, mirror discharge machining and so on. The application of the product is punching machine, and the packaging is cartons.

Drow Punch Mold Components have a wide range of applications, such as mold components punching, automotive parts punching, electronic parts punching, and more. It is suitable for a variety of materials, with high precision, long service life and high reliability. It is easy to operate, and can be used for mass production. The product is of high quality and excellent performance, and it is an ideal choice for various industries.

Customization:

Punch Mold Components

- Brand Name:

- Drow

- Model Number:

- Punch Mold

- Place of Origin:

- China

- Certification:

- ISO9001

- Minimum Order Quantity:

- 1set

- Price:

- Negotiable

- Packaging Details:

- Plastic box or Plastic film

- Delivery Time:

- 7~14 days

- Payment Terms:

- 100% T/T before shipping out goods

- Supply Ability:

- Depens on the drawing

- MOQ:

- 1 Set

- Processing Technology:

- Cylindrical Grinding,internal Circular Grinding,optical Profile Grinding, Flat Grinding, Thread Machining, Middle Speed Wire Cutting, Low Speed Wire Cutting , Mirror Discharge Machining And So On

- Shape:

- Customized

- Application:

- Punch Machine

- Material:

- Tungsten Carbide Or HSS

Punching Mold Components, Components Mold Punching, Mold Components Punching

Support and Services:

Punch Mold Components Technical Support and Service

We provide comprehensive technical support and service for Punch Mold Components. Our team of highly trained technicians are available to provide assistance with product installation, troubleshooting, and maintenance. We also provide customized solutions to meet your specific needs. Our experienced staff of engineers can help to design and customize components to meet your exact requirements.

In addition, we offer a wide range of services including product design, prototyping, testing and certification, production, and repair. We have access to the latest technology and equipment to ensure that your components are built quickly and accurately. Our team of experts is available to answer any questions you may have and provide you with the highest quality of service.

At Punch Mold Components, we strive to provide the best service and technical support possible. We are dedicated to ensuring that your components are built to last and meet all your specifications. For more information, please contact us today.

Support and Services:

Support and Services: