Introduction:

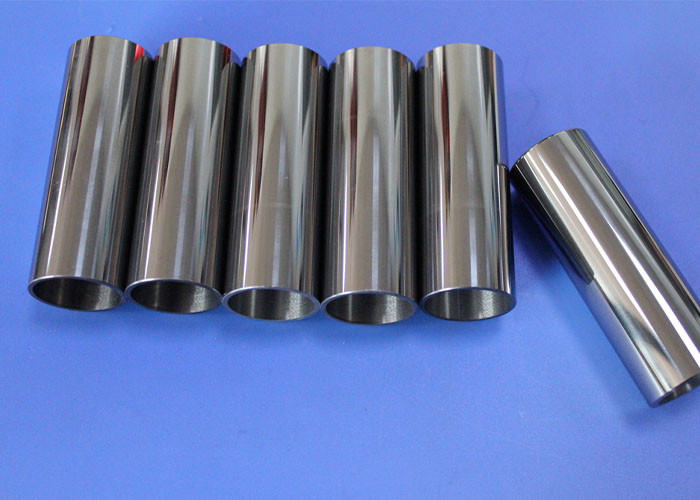

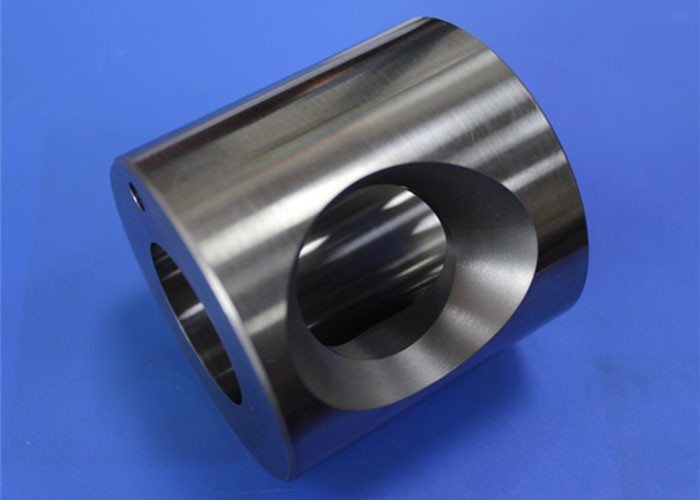

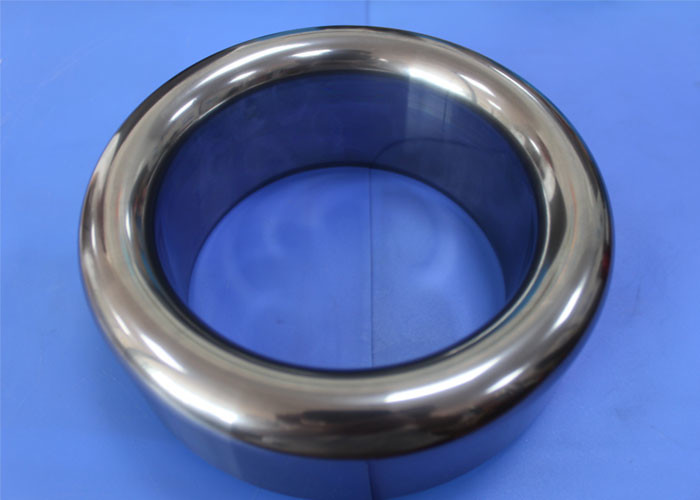

We specialize in the production of tungsten steel shaft sleeve, carbide sleeves, carbide sleeves pipe, tungsten steel sleeves and other carbide sleeve series of wear-resistant part sealing application

We can produce carbide shaft sleeves, carbide bushings, carbide casing and other series of the advantages of wear resistant, corrosion resistance, high temperature and vibration resistance.

As the industrial teeth and a typical representative of super-hard metal, cemented carbide is widely used for its great properties like wear resistance, corrosion resistance, high hardness and high strength, especially used for core working parts in some special extreme working conditions such as oil and natural gas, aerospace, underground drilling, automobile and ships, steel mines and other large-scale industries. The good performance and long service life of tungsten steel bearings are effective to improve industrial production efficiency. The demand for high-performance mold products in modern manufacturing has become an important method to improve production efficiency and economic development. For example, for the energy production industry, the high-quality equipment is the basic requirement for ensuring the long-term and safe operation of energy production lines. Thus, the performance requirements for mold products have become an inevitable focus. It is the high-end products of cemented carbide molds that have great promotion effects to aerospace, automotive, and downhole drilling industries. The corrosion resistance, high temperature resistance and wear resistance of cemented carbide bearings, carbide shaft sleeves, carbide sleeves and carbide molds are the basic requirements for the long-term operation of energy production machinery. Especially for precision petroleum machinery alloy bushing with high demand for dimensional accuracy, the production and processing operations require quite strict technical cooperation.

Technical parameters:

We provide customized processed tungsten steel bushings, carbide sleeves, carbide tubes, carbide bushings, and other products. The processing operations are produced according to the customer's specific drawings. The specifications of conventional carbide casings and hard alloy pipes are as follows:

- The maximum outer diameter: φ74mm

- The minimum outer diameter: φ5mm

- The maximum inner diameter: φ68mm

- The minimum inner diameter: φ0.1mm,

- The maximum length of carbide pipe: 360mm