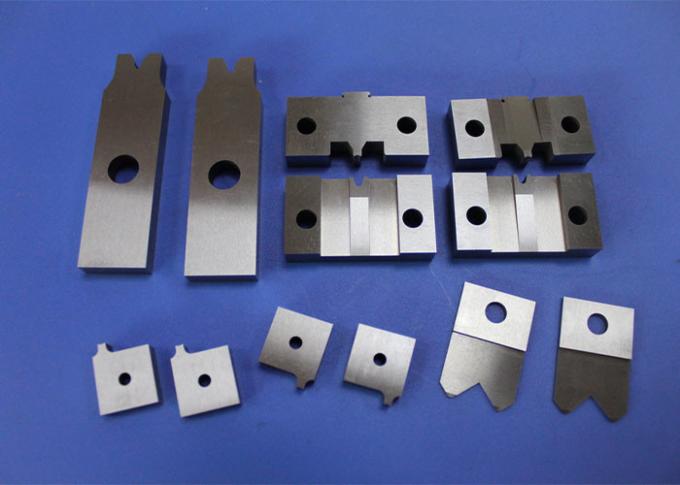

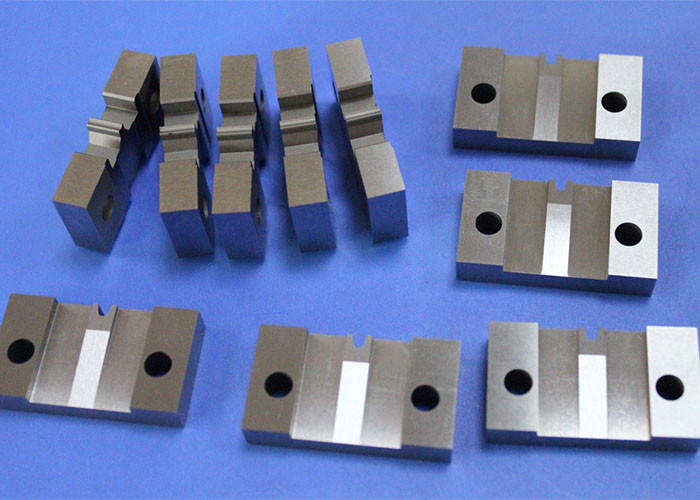

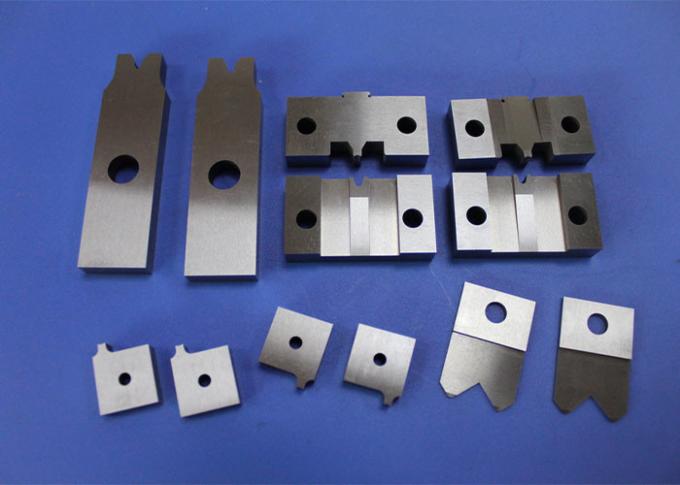

Customized Tungsten Carbide Processing Die Wearing Parts Square Tungsten Steel Tool

Sanxin Tungsten Carbide Manufacture, an expert who've been specialized in Carbide bits, blades, and OEM parts industry for 20 years.

| 1, | National high-tech enterprise certification |

| 2, | Processing High tolerance accuracy ±0.002mm |

| 3, | Wear-resistant, heat-resistant and anti-corrosion |

Tungsten carbid grade: K20, K10, K30 or other appointed high quality carbid grade

Non-magnetic carbide material can also be made for forming moulds of magnetic materials, with high hardness, long service life, good wear resistance and strong resistance to corrosion.

Advantages:

Cemented carbide wearing parts, also called wolfram carbide (WC) parts, are a commonly used high-end ring in the hardware machinery industry, because of its high hardness, good toughness, superior high and low temperature wear resistance, small adhesion, good corrosion resistance, high thermal conductivity, less friction coefficient, and acid and alkali corrosion resistance does not rust, easy maintenance and other characteristics.

With its good toughness, high temperature resistance and high wear resistance, the service life is 10~50 times longer than the general metal parts.