Introduction:

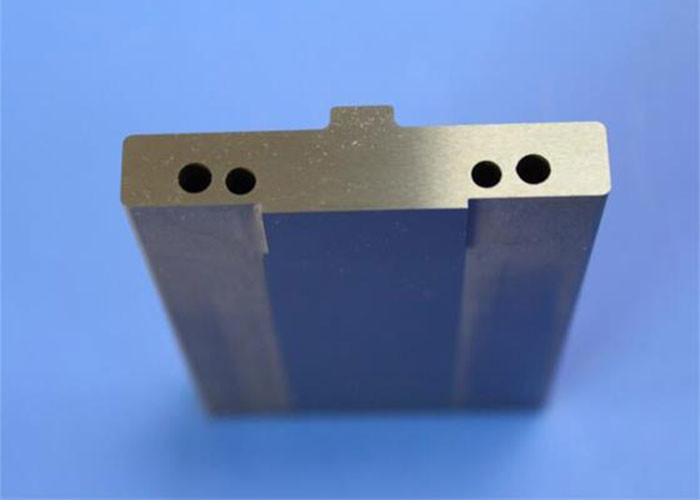

We can produce custom-made non-standard tungsten steel punch, square punch round punch needle.

The improvement of modern industrial production efficiency needs to improve the use performance of tool products. Good material is an effective way to improve work efficiency. Tungsten steel produced by powder metallurgy is a typical representative of super hard metal. Because of its high hardness, high strength and good toughness, it is a good choice for wear parts and high-quality punch needles. Tungsten steel punching needles are the core components of stamping die with its excellent properties. Tungsten steel punching needles and hard alloy punching needles refer to the same thing because of different regional names. The coastal areas of Guangdong are called tungsten steel punching needles. This is originated from Taiwan. The mainland called alloy punching needles, also called carbide punches. The punching needle series belongs to high-end precision tools according to physical properties. For continuous operation, especially for progressive stamping production with requirements of long service life and high accuracy, the performance of the carbide needle is greatly beyond other materials.

For the precision stamping processing of fiber tubes, it is required that each equipment should be continuously punched 100,000 times or more per day. The traditional metal material punching needle can hardly meet its working requirements in such high frequency working environment. For hard alloy, its excellent can satisfy the requirements, which is the expression of good performance. We can produce custom-made non-standard tungsten steel punch, square punch round punch needle according to customer's drawing and specific use conditions. With high-quality imported hard alloy materials, the products are specializing in high-speed precision stamping operation of fiber tube. It has many advantages, like stable performance, long-lasting service time and suitable precision dimensional tolerance, multi-channel precision machining process to ensure fiber tube punching tolerance consistent!

As a wear-resistant metal material, cemented carbide is the first choice for high-end wear parts, especially for some small and precise core working parts. The wear resistance ability of hard alloy wear parts completely exceeds other metal materials. Of course, due to the high hardness and high wear resistance of the alloy make the non-standard processing relatively complicated. The tungsten carbide processing of the hard alloy wear-resistant parts, especially the precision machining of the threaded tungsten steel parts, has higher requirements on equipment and technology. High-precision machining of hard alloy punching needles takes a long time, and the risk of scrapping rate is possible. For this reason, precision punching needles need contact us about the time in advance to avoid delaying normal production.

Technical parameters:

We can provide nonstandard custom-made punching needle tungsten steel. To meet the special applications, especially the tungsten steel processing products that require the internal thread precision machining operations, we can provide high standard tungsten steel. The high wear resistance is the basic requirement of tungsten steel products. Under the actual production operation of the progressive die, the combined die and the multi-station die, the tungsten steel die material is durable. According to the actual production operation requirements and customer specific drawings requirements as the accuracy tolerance requirements, the physical parameters of conventional tungsten steel non-standard production materials can be referred to as follows:

1. Grain size (um): 0.8 ~ 2.0

2. Cobalt content (Co%): 6 ~ 10

3. Density (g/cm³):14.45

4. Hardness HRA: 88 ~ 92

5. Bending strength (Mpa): 3200 ~ 3800

6. Young's modulus (Gpa): 570

7. Compressive strength (Mpa): 4700

If the customer has special requirements, we can provide tungsten steel products for production and processing according to the specific situation.