Product Description:

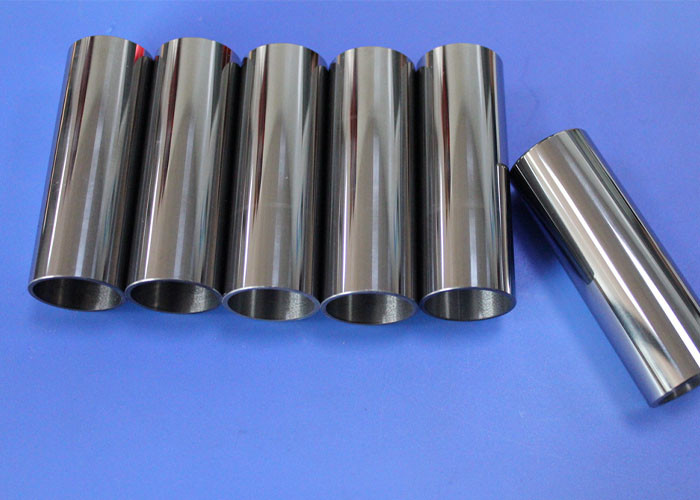

Tungsten Carbide Processing is a complex process that involves forming, hvof tungsten carbide coating, cutting, grinding, polishing, and more. It is used to manufacture tools for various industries, from aerospace to medical. Tungsten Carbide Processing requires precision and accuracy, as the forms, shapes, sizes, and tolerances must be precise, with maximum hardness of HRC90-HRC95. The forms available include round, square, or rectangular, all of which can be customized to meet the requirements of the customer. The process of Tungsten Carbide Processing also requires cutting, grinding, and polishing to achieve the desired shape, size, and hardness. With its high wear and abrasion resistance, hvof tungsten carbide coating is a popular choice for applications requiring long-term durability. Tungsten Carbide Processing offers high-precision results with a maximum tolerance of ±0.01mm.

Features:

The Benefits of Tungsten Carbide Processing

Tungsten carbide is highly valued for its exceptional properties, enabling it to be suitable for a wide range of applications. Its beneficial qualities make it an ideal option for processing components for a variety of industries.

The advantages of using tungsten carbide in manufacturing include:

- Exceptional Hardness: Tungsten carbide exhibits exceptional hardness, ranking among the hardest materials available, making it ideal for applications requiring wear resistance and durability.

- High Strength: Tungsten carbide processing results in products with high strength, enabling them to withstand heavy loads, impacts, and harsh environments without deformation or failure.

- Superior Wear Resistance: Tungsten carbide parts have excellent wear resistance, making them suitable for applications involving abrasion, erosion, and high-intensity wear conditions.

- Extended Tool Life: Products made from tungsten carbide have a significantly longer tool life compared to traditional materials, reducing the need for frequent replacements and increasing overall productivity.

- Corrosion Resistance: Tungsten carbide exhibits good resistance to corrosion, making it suitable for use in harsh chemical environments and applications where protection against corrosion is essential.

- High Temperature Resistance: Tungsten carbide maintains its strength and hardness even at high temperatures, enabling it to withstand extreme heat and thermal cycling without deformation or loss of performance.

- Excellent Thermal Conductivity: Tungsten carbide has high thermal conductivity, allowing for efficient heat dissipation and reducing the risk of thermal damage to the tool or workpiece during processing.

- Precision Machining: Tungsten carbide can be precisely machined to achieve complex shapes and tight tolerances, ensuring accuracy and consistency in the finished products.

- Versatile Applications: Tungsten carbide processing finds applications in various industries, including metalworking, mining, oil and gas, automotive, aerospace, and cutting tools, due to its exceptional properties and versatility.

- Cost-Effective Solution: Despite its initial higher cost compared to traditional materials, tungsten carbide processing offers a cost-effective solution in the long run due to its extended tool life, reduced downtime, and increased productivity.

Technical Parameters:

| Product Name | Features |

|---|

| Tungsten Carbide Processing | Heat Resistance: ≤900℃

Material: Tungsten Carbide

Processing Method: Cutting, Grinding, Polishing

Tolerance: ±0.01mm

Wear Resistance: Excellent

Lifespan: Long

Flexibility: Excellent

Corrosion Resistance: Excellent

Surface Finish: Smooth, Shiny |

Applications:

Tungsten carbide is widely used in many areas with its excellent wear resistance and mechanical strength. Its application can be divided into several parts. For example, it is used to make hardened tips and cutting edges for drills, end mills, taps, reamers and other tooling used in material removal processes. Moreover, applications such as bulldozer blades, excavator teeth, conveyor skip plates and chute liners often use tungsten carbide. In addition, forming and stamping dies used to shape metals and plastics incorporate tungsten carbide to withstand high pressures and repetitive use. Besides, tungsten carbide is also used as the composition of joint replacement components like knee and hip prosthetics for its biocompatibility. Furthermore, it is also an important material for oil and gas drilling operations, offering robust protection to drill bits when drilling through hard rock formations underwater. Moreover, wind turbine components often have tungsten carbide coating or inserts to protect wear surfaces in gear systems and blade pitch mechanisms. In addition, tungsten carbide is also widely used for downhole drilling tools like coring bits, underreamers and industrial core drills. Last but not least, it is also processed into particles and grains for abrasives, and is used in jewelry industry to produce decorative components for rings, cufflinks and pendants.

Support and Services:

Tungsten Carbide Processing Technical Support and Services

We offer high-quality technical support and services to ensure that you get the most out of your Tungsten Carbide Processing products. Our team of experts is available to help with any questions you may have, and to provide you with the most up-to-date information on our products and services.

We provide technical support for all of our Tungsten Carbide Processing products, including product selection, installation, and maintenance. We can also provide training and education on the best practices for using our products. Our team of experts is available to answer any questions you may have, provide guidance, and provide technical support as needed.

We also offer a range of services to help you get the most out of your Tungsten Carbide Processing products. We provide repair and maintenance services for all of our products, as well as custom fabrication services to create one-of-a-kind solutions for your specific needs. Our team of experts is available to answer any questions you may have, provide assistance, and ensure that you get the most out of your products.

Packing and Shipping:

Packaging and Shipping

Tungsten Carbide Processing products are packaged and shipped in accordance with the highest quality standards. All products are bubble-wrapped and sealed in heavy-duty cardboard or wooden boxes to ensure maximum protection. For international shipments, the packages are also wrapped in waterproof plastic film for added protection. All packages are marked with barcodes and customer tracking numbers for easier tracking.

We ship our products via air freight, ground transportation, and ocean freight. All orders are shipped with full insurance and tracking numbers to ensure safe and timely delivery. We always strive to provide the best customer service by offering competitive rates, careful handling, and excellent customer service.