Cylindrical Axle Tungsten Carbide Sleeve With Hole Customized Size

Main products

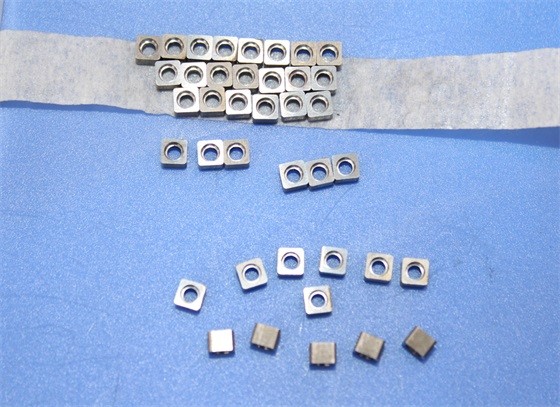

Normal cylindrical axle sleeve,cylindrical axle sleeve with slot, cylindrical axle sleeve with stage,axle sleeve with slot and convex stage,non-standard axle sleeve etc. There is a big choice of sizes and types of products.

We can recommend,design,develop.products and supply the products according to thr drawings and requirements of the customers.

Introduction:

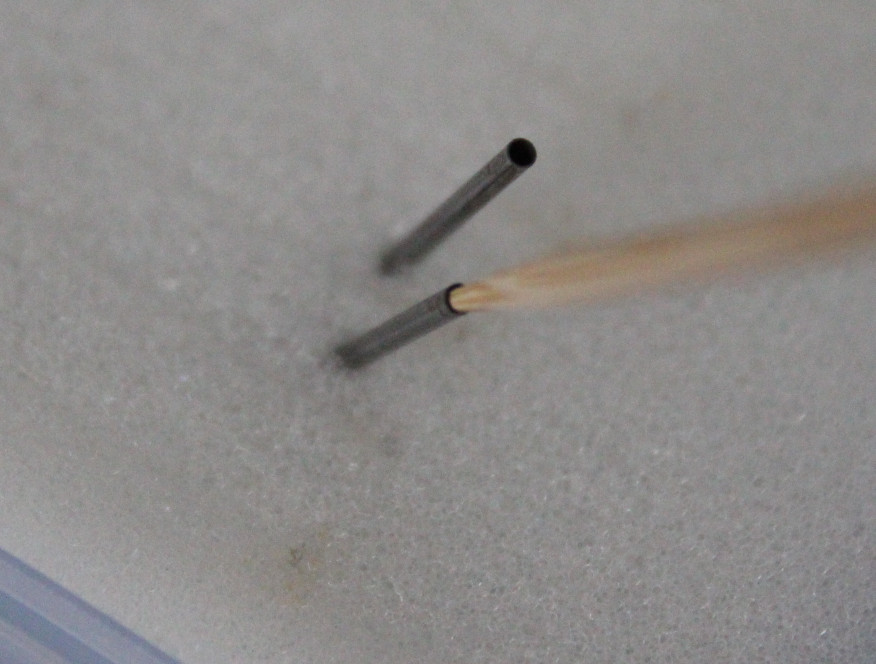

Our company specializes in the production of hard alloy thin-walled pipe, tungsten steel thin-walled pipe, hard alloy pipe sleeve and other series of thin-walled pipe sleeves with the functions of seismic and shock absorption, wear resistance and corrosion resistance.

Carbide thin-walled tubes, tungsten steel sleeves and hard alloy bushings are widely used in modern manufacturing industries for its good performance of high temperature resistance, corrosion resistance and wear resistance. Especially, it can be used as the core working components for certain special working places, such as oil and gas industry, automobile and ships, steel, mining and other industries. Using tungsten steel material is an effective way to improve working efficiency for its good performance and long-lasting service life.

Seismic and shock absorption is a great advantage of hard alloy thin-walled tubes. The super-hard metal prepared by powder metallurgy technology has the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance, small thermal expansion coefficient, etc. It is one of the good tool materials, widely used in many industrial production and processing operations. Good physical properties make the carbide sleeve series of good stability in shock absorption. The integrity of the hard alloy thin-walled tube material makes high hardness and small deformation.

Technical parameters:

We can provide non-standard customized carbide alloy bushings, carbide sleeves, carbide bushings, etc. According to customers’ specific drawings, the conventional carbide casing, carbide pipe and other dimensions are as follows:

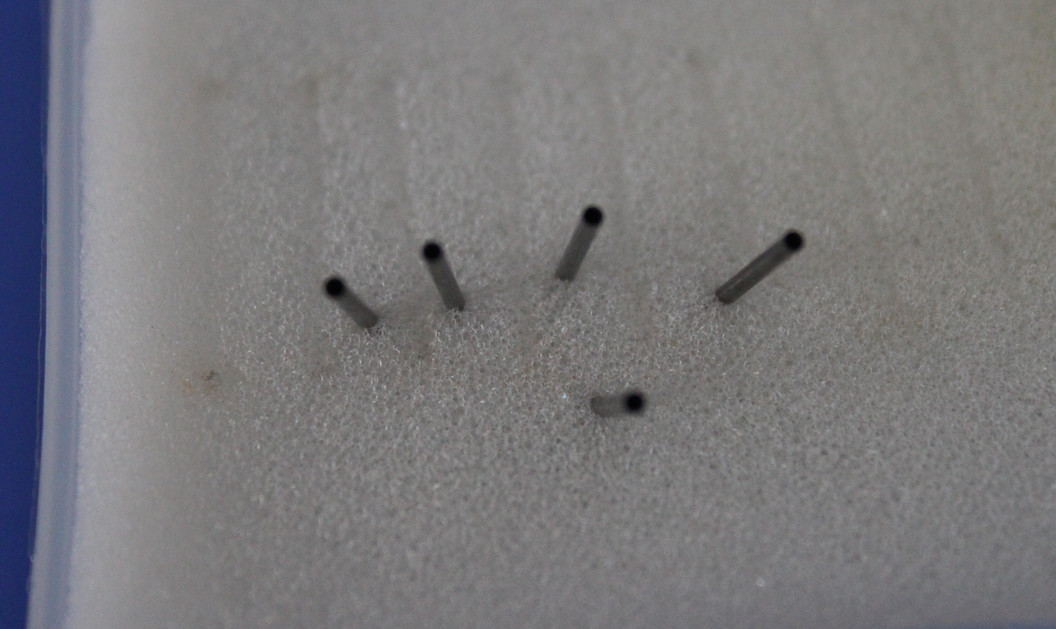

1. The maximum outer diameter: φ74mm

2. The minimum outer diameter: φ5mm

3. The maximum inner diameter: φ68mm

4. The minimum inner diameter: φ0.1mm

5. The maximum length of carbide pipe: 360-420mm

According to the actual use, we provide non-standard custom-made production and processing of hard alloy thin-walled tubes, such as φ25*φ22*320 series specifications.

Advantage:

As a cemented carbide production and processing manufacturer, relying on the advanced carbide technology and complete industry chain in Zhuzhou, we provide customers with hard alloy sleeves, carbide mold parts, tungsten steel large-cavities, wear-resistant non-standard shaped carbide products. according to the customer's drawing requirements and our professional production equipment and rich experience as guarantee, we select high-quality materials to meet customers' demand.