Double Hole Tungsten Carbide Nozzle / Alloy Tungsten Steel Nozzle

Introduction:

Carbide nozzles are also known as tungsten carbide nozzles. The commonly used hard alloy is a tungsten-cobalt alloy. The tungsten-cobalt alloy is used with refractory metal tungsten carbide as hard phase, and transition metal (Co, etc.) used as binder phase. It is prepared by powder metallurgy technology to be super-hard alloy, with the advantages of high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance, small coefficient of linear expansion, etc. It is one of the excellent tool materials, widely used in many industrial production and processing operations. Because its main component is tungsten carbide, it is often referred to as tungsten carbide products.

Technical parameters:

The precision processing of tungsten steel nozzle tungsten carbide nozzle is mainly in accordance with the customer's drawings and equipment requirements.

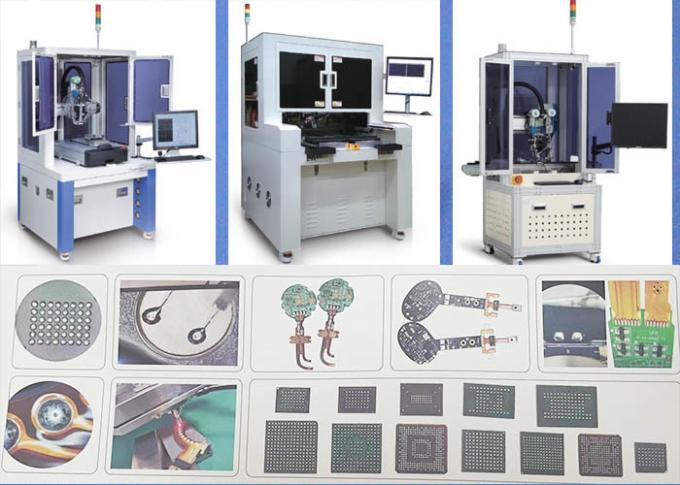

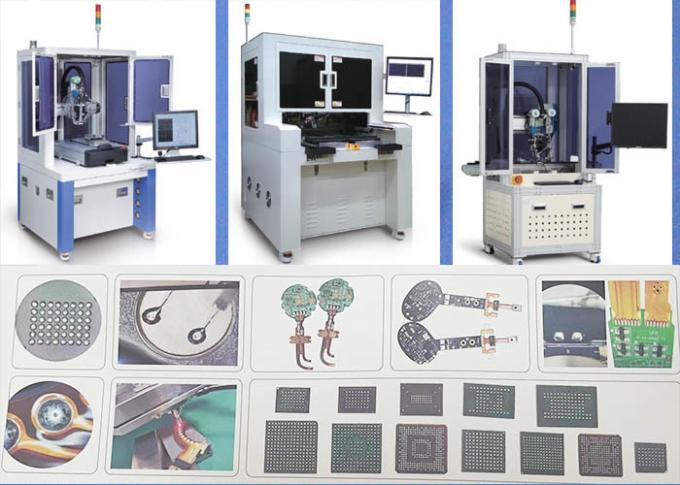

The excellent performance of tungsten steel nozzle core is unmatched by other tool materials, especially for long-time operation of conditions of high temperature and corrosion. Tungsten steel produced by powder metallurgy process is good choice for wear parts. As a cemented carbide production and processing manufacturer, we have been committed to providing high-performance cemented carbide products for the mechanical industry. From blank production to deep processing, relying on the advanced cemented carbide production technology and the complete cemented carbide industrial chain in Zhuzhou, we provide customers with high-quality tungsten carbide nozzle and other tungsten steel processing precision products. With the professional production equipment and rich experience as guarantee, we select high-quality materials to meet customers' demand.

The tungsten carbide nozzle is used as a mechanical equipment product part, with the full name: NOZZLE 500UM MODIFY. In addition to ensuring the dimensional accuracy of the drawings, the surface of the part cannot be scratched, and the blunt edge should be deburred and sharpened. The unmarked chamfer is C0.5 and the unmarked round corner is R0.5.

| Name: | Tungsten Carbide Nozzle | Pin Ceramic Nozzle: | φ0.036(-0.001)*2 |

|---|

| Tungsten Steel Slider Insert Head: | φ0.128 (±0.001) | Type: | Tungsten Carbide Nozzle |

|---|

| Model: | Tungsten Steel Nozzle | Feature: | High Hardness |

|---|

Advantages:

Tungsten steel nozzles used for high-precision equipment require good physical stability as the basis, especially for high-temperature, corrosion-resistant and long-lasting operation. It is a good choice to use cemented carbide materials. From the selection of raw materials to the completion of deep processing of tungsten steel, each procedure will directly affect the performance of the cemented carbide nozzle. As a cemented carbide production and processing manufacturer, we have been committed to providing high-performance cemented carbide products for the mechanical industry. From blank production to deep processing, relying on the advanced cemented carbide production technology and the complete cemented carbide industrial chain in Zhuzhou, we provide customers with high-quality tungsten carbide nozzle and other tungsten steel processing precision products. With the professional production equipment and rich experience as guarantee, we select high-quality materials to meet customers' demand.

Safe packages:

Applications Like Laser Soldering Tungsten Carbide Tin Ball Nozzle: