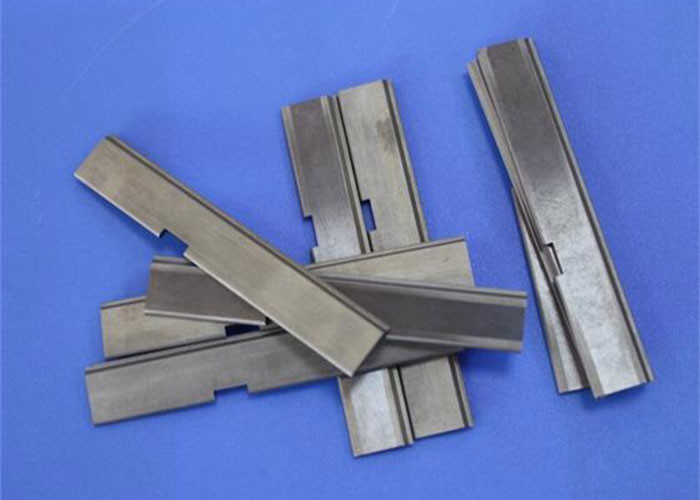

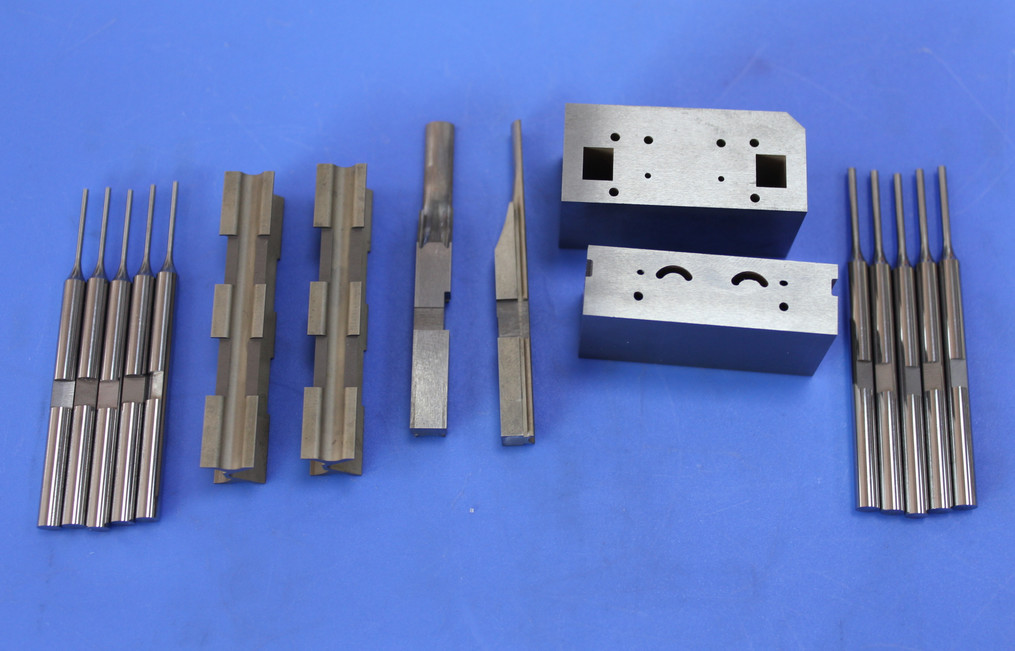

Durable Progressive Punching Die Carbide Mold According To Drawings Or Samples

Introduction:

We provide high-quality hard alloy (tungsten steel) progressive punching die, can be processed according to drawings or samples.

The cemented carbide (tungsten steel) progressive die produced by our company is highly recognized by the customers for its excellent performance, high quality and affordable price.

The unique production process effectively controls the internal stress of the large-size mold material and avoids the cracking of the cutting process.

The unique alloy material enhances the corrosion resistance of the alloy during electrical processing and improves the performance and service life of the mold.

Technical parameters:

Application and performance of the cemented carbide (tungsten steel) graded blanking die material

| Grade | Co% | Hardness HRA | Density g/cm³ | Bending strength Mpa | Elastic Modulus Gpa | Applicable punching materials |

| SX10 | 10 | 91.7 | 14.4 | 4300 | 490 | A sheet of copper, aluminum or the like having a thickness of less than 0.2 mm. |

| SX15 | 12 | 92.5 | 14.1 | 4500 | 460 | Sheets of copper, aluminum and stainless steel. |

| SX20 | 13 | 90.6 | 14.1 | 4100 | 460 | Sheets of copper, aluminum and so on. Highly versatility. |

| SX35A | 12 | 89.8 | 14.2 | 3400 | 470 | Cold rolled sheet such as Q195 and SPCC |

| SX36 | 15 | 89.4 | 13.8 | 3900 | 430 | EI film, SPCC board, etc. |

| SX40A | 12 | 88.9 | 14.2 | 3300 | 470 | Cold rolled sheet such as Q195 and SPCC |

| SX45A | 15 | 87.9 | 13.9 | 3200 | 440 | Silicon steel sheet, cold rolled sheet, etc. |

| SX55 | 20 | 86.4 | 13.5 | 3100 | 390 | Silicon steel sheet, upper and lower punch |

Advantages:

- The professional material engineer selects the material grade and superfine particle raw powder according to your requirements.

- Advanced precision processing equipment + unique process.

- high wear resistance, long service life, greatly reducing the frequency of edge grinding and maintenance.