Product Description:

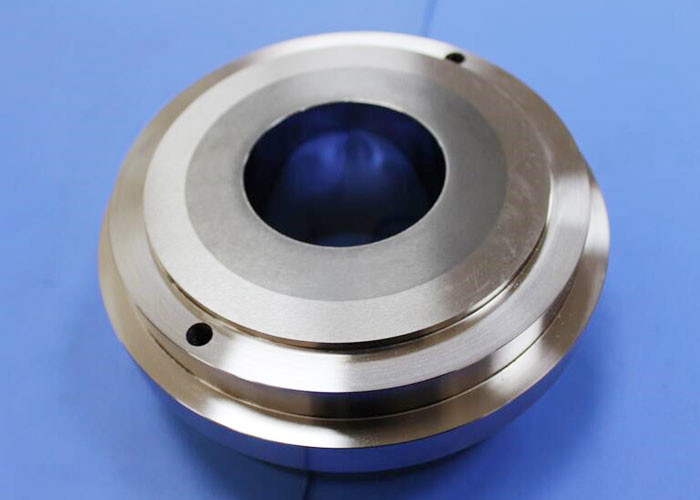

Tungsten Carbide Processing is a high-precision product produced from tungsten carbide material, with a density of 14.5-15.0g/cm3 and a tolerance of ±0.01mm. It has excellent heat resistance, up to 900℃, making it ideal for use as a tungsten cutting tool or for tungsten carbide plating. With its superior performance and high quality, Tungsten Carbide Processing is the perfect choice for your tungsten carbide processing needs.

Features:

Tungsten carbide parts are well-known for their exceptional hardness and strength, ranking among the hardest materials available. This makes them perfect for applications that require wear resistance and durability.

Tungsten carbide can withstand heavy loads, impacts, and harsh environments for an extended period of time without any deformation or damage. It also has superior wear resistance, making it suitable for applications involving abrasive, corrosive, and high-intensity wear conditions.

In addition, tungsten carbide-made products have a much longer tool life compared to conventional materials, allowing for fewer replacements and higher overall productivity. Furthermore, these parts are also corrosion-resistant, making them suitable for use in harsh chemical environments.

Moreover, tungsten carbide exhibits exceptional high-temperature resistance and good thermal conductivity. It maintains its strength and hardness even at extremely high temperatures and has efficient heat dissipation to reduce the risk of thermal damage.

Lastly, tungsten carbide lends itself to precision machining, enabling complex shapes and tight tolerances. It is also used in numerous industries such as metalworking, oil and gas, automotive, pre-cutting tools, and aerospace due to its versatility. Despite its cost being higher than traditional materials, tungsten carbide offers a cost-effective solution in the long run.

Technical Parameters:

| Product Name | Tungsten Carbide Processing |

|---|

| Surface Finish | Smooth, Shiny |

|---|

| Size | Customized |

|---|

| Material | Tungsten Carbide |

|---|

| Wear Resistance | Excellent |

|---|

| Impact Resistance | Excellent |

|---|

| Density | 14.5-15.0g/cm3 |

|---|

| Lifespan | Long |

|---|

| Flexibility | Excellent |

|---|

| Heat Resistance | ≤900℃ |

|---|

| Tungsten Carbide Forming | HVOF Tungsten Carbide |

|---|

| Tungsten Carbide Processing | Yes |

|---|

Applications:

Tungsten carbide has many applications in the industrial and jewelry sectors. For example, it is commonly used to form hardened tips and cutting edges for drills, end mills, taps, reamers and other tooling used in material removal processes. Additionally, it can be found in wear parts such as bulldozer blades, excavator teeth, conveyor skip plates, and chute liners, due to its excellent wear resistance.

It is also used to form dies and molds that can withstand high pressures and repetitive use, and to create orthopedic implants like knee and hip prosthetics for its biocompatibility and mechanical strength. Tungsten carbide is even incorporated into drilling tools, oil and gas drilling operations, as well as wind turbine components and exploration equipment.

Aside from industrial uses, tungsten carbide is process into particles and grains for use in coated and bonded abrasives for polishing and grinding applications. Lastly, it is used for decorative components in the jewelry industry for rings, cufflinks, and pendants, thanks to its density and color properties.

Support and Services:

Tungsten Carbide Processing Technical Support and Service

We provide our customers with comprehensive technical support and services for Tungsten Carbide processing. Our team of experienced engineers is on hand to provide advice and assistance on all aspects of the process, from selection of the right grade of tungsten carbide to the correct processing technique.

We offer a comprehensive range of services including:

- Assessment of your current processing methods

- Advice on the best grade of tungsten carbide for your application

- Guidance on the correct techniques for machining tungsten carbide

- Assistance with troubleshooting and problem-solving

- Technical support for new processes and products

Our team is committed to providing the highest level of technical support and service to ensure that your Tungsten Carbide processing is successful.

Packing and Shipping:

Tungsten Carbide Processing Packaging and Shipping:

- Tungsten Carbide Processing products are carefully packaged to minimize the risk of damage during transit.

- All products are securely boxed or wrapped, with extra padding and bracing provided as necessary.

- We use only the highest quality packaging materials to ensure the safe arrival of your products.

- We ship our products using reliable and efficient courier services.

- We also offer express shipping for urgent orders.