Product Description:

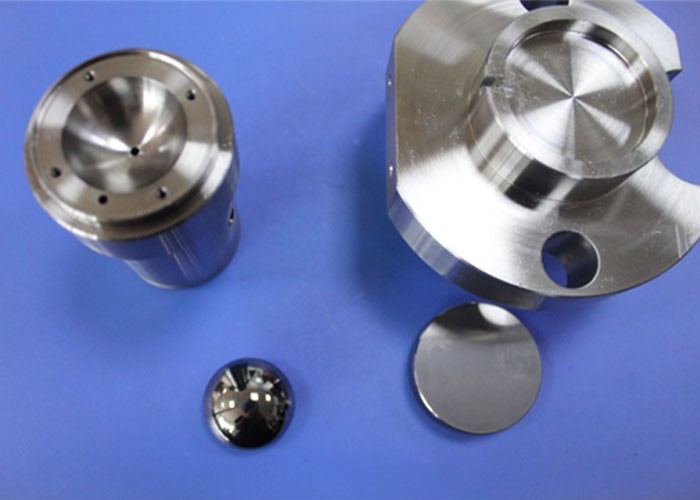

Tungsten Carbide Processing is a highly wear-resistant tool material that is ideal for a variety of machining operations. It is made from tungsten carbide, a material renowned for its strength and hardness, and is able to hold its shape against high heats and heavy loads. Tungsten Carbide Processing is available in Round, Square and Rectangular shapes, and is precise to ±0.01mm in tolerance. It is the perfect choice for a wide range of applications, such as tungsten cutting tools, tungsten cutting tools and tungsten carbide plating. With its outstanding wear resistance and durability, Tungsten Carbide Processing is the ideal solution for any machining needs.

Features:

Exceptional Hardness

Tungsten carbide stands out from other materials due to its exceptional hardness. It ranks amongst the hardest materials available, and as such is ideal for applications that require superior wear and durability.

High Strength

After tungsten carbide processing, materials gain great strength that can withstand heavy loads and allow them to be used in harsh environments without any deformation or breakage.

Superior Wear Resistance

Tungsten carbide parts are extremely resilient, making them suitable for dealing with abrasion, erosion, and other intense wear levels. This allows them to be used in harsh environments where traditional materials may not suffice.

Extended Tool Life

Products manufactured with tungsten carbide enjoy an extended life cycle, cutting down the need for frequent replacements which in turn increases overall productivity.

Corrosion Resistance

Tungsten carbide is highly resistant to corrosion, making it a great choice for areas exposed to harsh chemicals. Protection against corrosion is essential in such environments.

High Temperature Resistance

Tungsten carbide is capable of withstanding extremely high temperatures whilst still retaining its strength and hardness. It does not experience any deformation, ensuring effective performance in the long run.

Excellent Thermal Conductivity

The thermal conductivity of tungsten carbide enables efficient dissipation of heat without risking thermal damage to the tool or workpiece.

Precision Machining

Precise machining allows complex shapes and tight tolerances to be achieved with tungsten carbide, ensuring accuracy and consistency in the finished result.

Versatile Applications

Due to the exceptional properties of tungsten carbide processing, it find uses in various industries such as metalworking, mining, automotive, aerospace, and more.

Cost-Effective Solution

Although it may seem like a more expensive option at first, tungsten carbide is the better cost-effective choice in the long run. Reduced downtime, extended tool life, and increased productivity make it a wise investment.

Technical Parameters:

| Property | Specification |

|---|

| Corrosion Resistance | Excellent |

| Tolerance | ±0.01mm |

| Shape | Round, Square, Rectangular |

| Flexibility | Excellent |

| Impact Resistance | Excellent |

| Processing Method | Cutting, Grinding, Polishing |

| Product Name | Tungsten Carbide Processing |

| Density | 14.5-15.0g/cm3 |

| Hardness | HRC90-HRC95 |

| Material | Tungsten Carbide |

Applications:

Tungsten carbide is a widely used material in a variety of applications. It is known for its excellent wear resistance and its biocompatibility and mechanical strength. These qualities have allowed for several applications, such as cutting tools, wear parts, dies and molds, orthopedic implants, drill bits, wind turbine components, exploration equipment, abrasives, and jewelry industry components.

Cutting tools, like drills, end mills, taps, and reamers, will often incorporate tungsten carbide for its hardness. This also makes it ideal for applications like bulldozer blades, excavator teeth, conveyor skip plates, and chute liners. In addition, it is often used to make forming and stamping dies that are used to shape metals and plastics, and it is incorporated into joints replacement components such as knee and hip prosthetics.

Tungsten carbide is also common for drill bits used by oil and gas drilling operations, as well as for optimizing wind turbine components like gear systems and blade pitch mechanisms. Further, it is used for downhole drilling tools such as coring bits, undereamers, and industrial core drills. Abrasive particles and grains also take advantage of tungsten carbide's hardness. Finally, its density and color properties makes it a great choice for decorative components in the jewelry industry.

Support and Services:

Tungsten Carbide Processing Technical Support and Services

Our team provides technical support and services for the processing of tungsten carbide products. We have a comprehensive range of expertise and experience that enables us to provide you with the best quality products and services.

Our services include:

- Design and engineering assistance

- Processing and machining

- Heat treatment and brazing

- Casting and finishing

- Quality control and testing

We use the latest technology and techniques to ensure that our products meet the highest standards. We also provide technical support and advice to help you make the most of your tungsten carbide processing needs.

Packing and Shipping:

Packaging and Shipping

Tungsten Carbide Processing products are packaged in sturdy boxes and sealed to ensure that they reach their destination safely. Packaging materials used include bubble wrap, foam, bubble bags, cardboard, and other appropriate materials. All of our products are shipped via FedEx, UPS, or USPS.