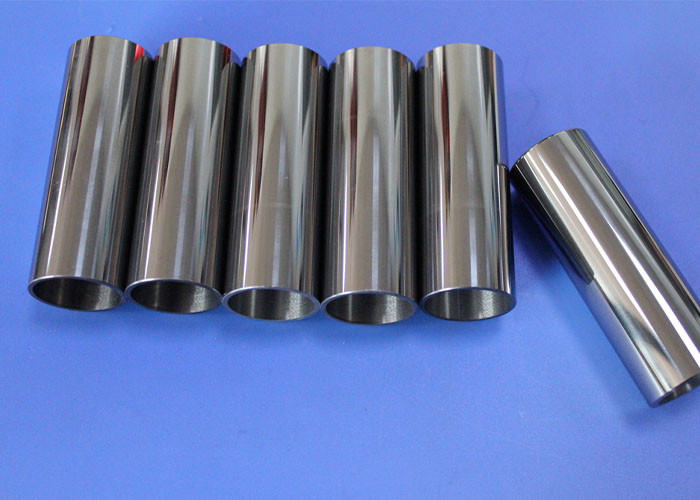

Product Description:

Tungsten Carbide Processing is a superior machining material with excellent wear resistance, high density, and heat resistance. It features a density of 14.5-15.0g/cm3 and a tolerance of ±0.01mm, so you can be sure that you will get the perfect parts you need. The HVOF tungsten carbide is designed for wear-resistant applications and provides high-efficiency machining and long-lasting performance. As such, it is ideal for a wide range of industries, including automotive, aerospace, and medical.

Tungsten Carbide Processing is the superior choice for high-performance machining, offering excellent wear resistance and heat resistance up to 900℃. Its unique properties make it suitable for a wide variety of applications, including cutting, drilling, tapping, and milling. With our advanced HVOF process, you can expect reliable performance, precision, and accuracy.

For the highest quality and performance, Tungsten Carbide Processing is the ideal solution for all your machining needs. With its excellent wear resistance, high density, and heat resistance, it is the ideal choice for machining tungsten carbide. For reliable and consistent performance, choose Tungsten Carbide Processing.

Features:

Tungsten carbide is exceptionally hard, ranking among the toughest materials available, making it perfect for applications that involve abrasion, erosion, and high-intensity wear conditions. It excels in heavy loads and harsh environments due to its immense strength. Additionally, it offers good corrosion resistance, making it perfect for use in chemical-heavy conditions. Being able to survive at high temperatures, it provides for efficient heat dissipation, which prevents thermal damage in the tool or workpiece.

Tungsten carbide provides excellent precision machining and a longer tool life. Furthermore, it is very versatile and can be used in many industries, such as metalworking, mining, oil and gas, automotive, aerospace, and cutting tools. Despite its higher cost, it offers a cost-effective solution in the long run due to its robustness, minimal downtime, and increased productivity.

Technical Parameters:

| Property | Tungsten Carbide Processing |

| Size | Customized |

| Density | 14.5-15.0g/cm3 |

| Impact Resistance | Excellent |

| Heat Resistance | ≤900℃ |

| Material | Tungsten Carbide |

| Hardness | HRC90-HRC95 |

| Shape | Round, Square, Rectangular |

| Wear Resistance | Excellent |

| Flexibility | Excellent |

| Lifespan | Long |

| Processing | HVOF, Machining, Coating |

Applications:

Tungsten Carbide in Manufacturing

Tungsten carbide is widely used in a variety of industrial applications ranging from cutting tools, wear parts, dies and molds, orthopedic implants, drill bits, wind turbine components, exploration equipment, abrasives to jewelry industry.

Cutting Tools

Tungsten carbide is used for making hardened tips and cutting edges for drills, end mills, taps, reamers and other tooling used in material removal processes.

Wear Parts

Applications like bulldozer blades, excavator teeth, conveyor skip plates and chute liners which require excellent wear resistance utilize tungsten carbide extensively.

Dies and Molds

Tungsten carbide is commonly used forming and stamping dies which are used to shape metals and plastics. Its strength and durability are necessary for withstanding the high pressures and repetitive use.

Orthopedic Implants

Joint replacement components such as knee and hip prosthetics contain tungsten carbide due to its biocompatibility and mechanical strength.

Drill Bits

Oil and gas drilling operations require robust tungsten carbide bits to efficiently drill through the hard rock formations underwater.

Wind Turbine Components

Tungsten carbide coating or inserts are used to cover the wear surfaces in the gear systems and blade pitch mechanisms of wind turbines.

Exploration Equipment

Coring bits, underreamers, and industrial core drills in exploration operations take advantage of the hardness of tungsten carbide.

Abrasives

Tungsten carbide is processed into particles and grains for coating andbonded abrasives which are used for polishing and grinding in various industries.

Jewelry Industry

Various decorative components for jewelry such as rings, cufflinks and pendants are made of tungsten carbide because of its high density and color properties.

Support and Services:

Tungsten Carbide Processing Technical Support and Service

We offer technical support and service for Tungsten Carbide Processing. Our team of experts is available to provide advice and guidance on a range of topics including:

- Processing methods

- Production optimization

- Material selection

- Troubleshooting

- Repair and maintenance

- Environmental and safety compliance

We also provide specialized software and equipment for Tungsten Carbide Processing. Our experts can work with you to customize a solution to meet your specific needs and requirements.

Packing and Shipping:

Packaging and Shipping

Tungsten Carbide Processing is packaged and shipped in accordance with international regulations and standards. All products come in sealed containers and are packed in a secure manner to ensure their safe arrival. All shipments are tracked and monitored throughout the entire shipping process.

We use the most reliable international couriers and freight companies to ensure that our products are delivered on time. We also provide our customers with real-time tracking information for their shipments.