It’s hundreds of years that Diamond has been used in machining as a superhard tool material. From the end of the 19th century to the beginning of the 20th century, the tool material was mainly represented by high speed steel. In the 1950s, synthetic diamonds were synthesized in Sweden and the United States, and the cutting tools were stepped into the period represented by superhard materials. In the 1970s, people used high pressure synthesis technology to synthesize polycrystalline diamond PCD, which solved the problem of the rare and expensive natural diamonds, and expanded the application range of diamond tools to aerospace, automotive, electronics, stone, woodworking and other fields.

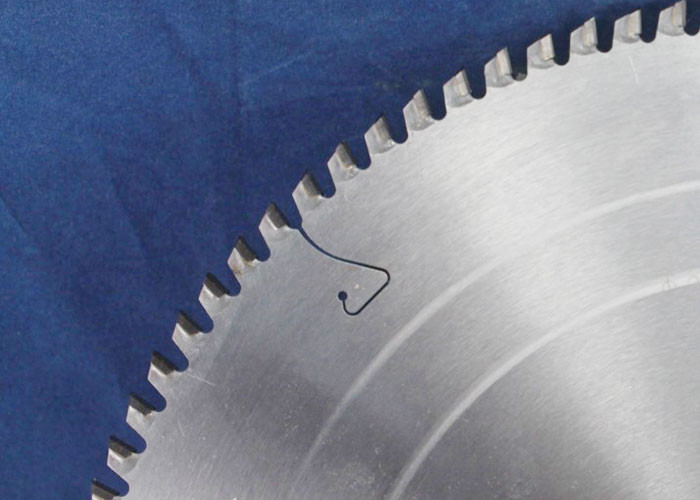

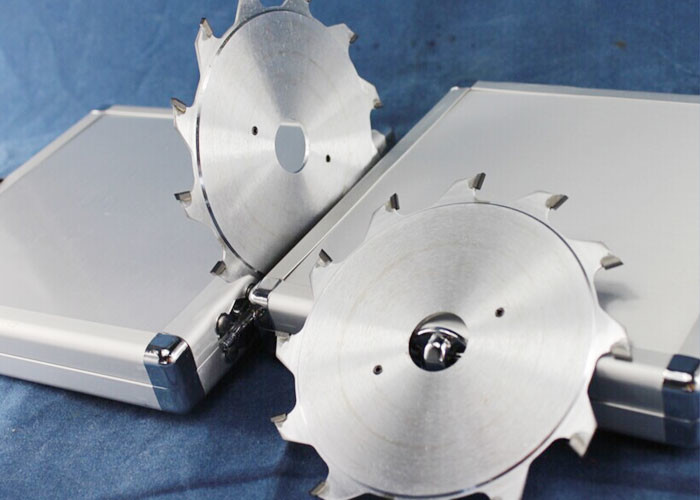

Diamond saw blades have high hardness, high flexural strength, good thermal conductivity and wear resistance, high precision cutting can achieve high precision and processing efficiency. The above characteristics of the diamond saw blade are determined by the state of the diamond crystal. The domestic PCD saw blade market is expanding continuously. At present, the PCD tool processing is extended to stone processing and wood processing. Especially in the wood industry, diamond saw blades have become an indispensable cutting tool, mainly for particle board, MDF, ecological board, melamine board, etc. The diamond saw blade is mainly composed of two parts; the base and the cutter head. The base body is the main support part of the bonding cutter head, and the cutter head is the part which is cut during use. The cutter head is continuously consumed in use, and the base body does not. The cutter head can cut is because it contains diamond, which is the hardest material at present, and it rubs and cuts the object to be processed in the cutter head. The diamond particles are wrapped in metal inside the cutter head.

Technical Parameters

Product Name: PCD Diamond Saw Blade

Product specifications: φ300 × φ30 × 3.2 × 96T × 11 °

Product specifications: φ350 × φ30 × 3.5 × 96T × 11 °

Product specifications: φ380 × φ60 × 4.4 × 72T × 11 °

Product hardness: 10000 (HV)

Product base: high quality alloy steel

Saw blade material: PCD composite diamond

Product wear resistance durability: 50-150 times

Configuration advantage

Eco plate diamond woodworking saw blade, Zhuzhou Sanxin PCD diamond saw blade specializes in continuous and long lasting dry cutting operation of particle board. The detailed physical parameters of the diamond saw blade are as follows:

Product Name: Diamond saw blade

Diamond saw blade particleboard dry cutting, for large woodworking operations, product specifications φ300 × φ30 × 3.2 × 96T × 11 °, selected German high quality alloy steel as the base, welding high quality PCD composite diamond cutter head forming, good dynamic balance and science heat dissipation design ensures the longevity of the cutting work of wood chipboard production. The regular use period is at least one month. The test detects the service life of 50 pieces of carbide saw blades on the market.

Based on quality, focus on brand, customers’ satisfaction is the best value we pursue. Our company specialize in the production of PCD composite diamond saw blades with high quality alloy steel as the base. The welded high performance PCD composite diamond cutter head is exquisitely formed, and the whole process is mechanically standardized. It ensures the uniformity of every detail of the production process, well designed dynamic balance and Scientifically created heat dissipation ensures that the PCD composite diamond saw blade is consistent with the service life of the woodworking cutting operation and the cutting operation. It can be used for more than 300-400 hours continuously, and can be used for multiple times. It has a long service life and is perfect. Woodworking furniture cutting operations provide strong product technical support to increase production efficiency and reduce production costs.