Introduction:

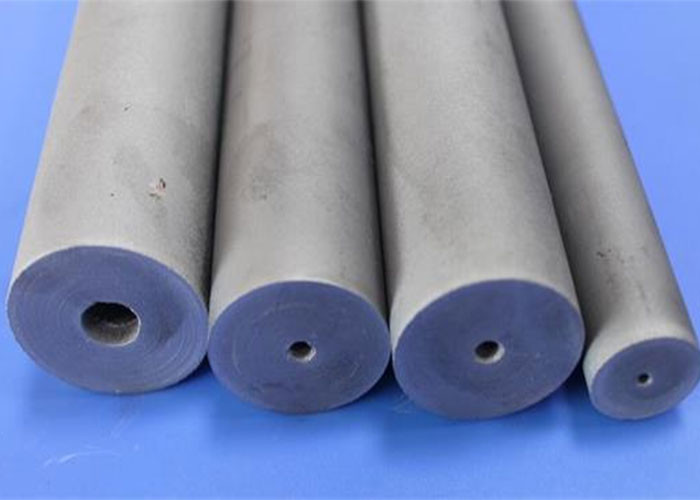

We can provide customized tungsten steel mold sleeves for the batch use of granulation equipment.

The granulation equipment is a molding machine that can manufacture materials into specific shapes. It is generally classified into roll dry granulator, rotary drum granulator and dry roll-pressing granulator. The main granulator models include rotary belt type condensing granulator, contract-tooth type powder-extrusion granulator ccand kneading type powder-extrusion granulator. To improve the performance and service life of the granulation equipment, it is a good choice to use carbide mold sleeve as the core working parts for its good physical properties.

As super-hard metal material, cemented carbide has good physical stability, especially its high hardness, high strength, high wear resistance and corrosion resistance. It is good tool for industrial mass production. With the requirements of wear resistance, the finished product produced by the hard alloy mold sleeve can reflect its good performance.

Technical parameters:

The wear-resistant hard alloy mold sleeves are custom-made according to the drawings of the granulation equipment manufacturer. The specification is φ14*1*φ13*φ9*60.

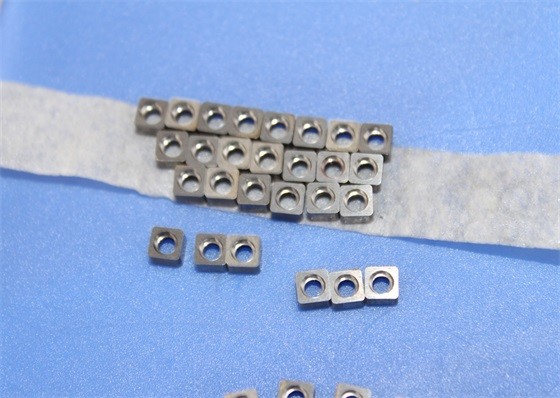

The 1mm cemented carbide sleeve is mainly used for assembly. Because of the high hardness of the cemented carbide and the relatively flimsy hanging table, the transportation requires special attention to avoid the impact deficiency of assembly. A granulation equipment needs 250 pieces of wear-resistant cemented carbide molds, with the requirements of uniform dimension and good physical stability.

Advantages:

The machining tolerance of cemented carbide processing is ±0.002. Carbide die sets are customized for production and processing. According to the specific requirements of customers, it is customized for specific series of corrosion resistance, high temperature resistance, wear resistance, acid and alkali resistance. Relying on the complete cemented carbide processing industrial systems and technology in Zhuzhou, we can provide high-quality wear-resistant parts, tungsten carbide alloy bushings, carbide die sets, carbide shafts, carbide bushings, carbide sleeves, etc.