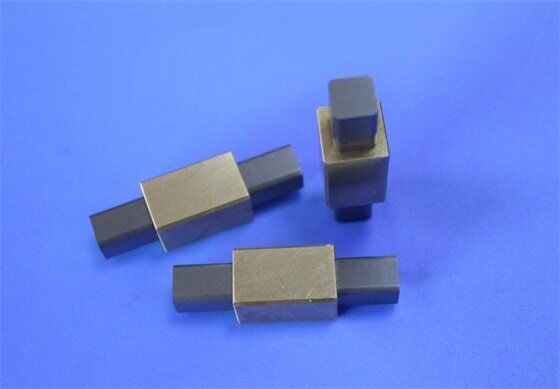

High Density Tungsten Carbide Mold Parts , Custom Tungsten Carbide Pins

Tungsten Carbide Mold Parts Introduction:

We can process precision tungsten steel punching needles, tungsten steel punches, tungsten steel forming needles, tungsten steel inserts, t tungsten steel core needles and other series of hard alloy round rods.

Using good materials is a good way to improve the production efficiency. Cemented carbide produced by powder metallurgy is what we usually said tungsten steel. With high hardness, high strength and good toughness, tungsten steel is a good choice for wear parts and high-quality punch needles. As the core parts of stamping die, tungsten steel punching needle is widely used for its excellent physical properties. It belongs to high-end precision tools. For continuous operation, especially for progressive stamping production with requirements of long service life and high accuracy, the performance of the carbide needle is greatly beyond other materials. Tungsten steel precision parts products used in precision molds and equipment require good physical stability as the basis, especially the durability and wear resistance are undoubtedly the key points, which can fully meet the requirements for tungsten steel materials.

Tungsten Carbide Mold Parts Technical parameters:

We can provide nonstandard custom-made punching needle tungsten steel. For special applications, especially the tungsten steel processing products that require the internal thread precision machining operations, we can provide high standard tungsten steel. The high wear resistance is the basic requirement of tungsten steel products. Under the actual production operation of the progressive die, the combined die and the multi-station die, the tungsten steel die material is durable. According to the actual production operation requirements and customer specific drawings requirements as the accuracy tolerance requirements, the physical parameters of conventional tungsten steel non-standard production materials can be referred to as follows:

1. Grain size (um): 0.8 ~ 2.0

2. Cobalt content (Co%): 6 ~ 10

3. Density (g/cm³):14.45

4. Hardness HRA: 88 ~ 92

5. Bending strength (Mpa): 3200 ~ 3800

6. Young's modulus (Gpa): 570

7. Compressive strength (Mpa): 4700

If the customer has special requirements, we can provide tungsten steel products for production and processing according to the specific situation.

| Name: | Tungsten Carbide Mold Parts | Feature: | High Density |

|---|

| High: | Costum | Type: | Tungsten Steel Punch Processing |

|---|

| Model: | Carbide Punching Needle Production | Tungsten Steel Pin: | Double-hole Insert Head |

|---|