Introduction:

The concept of cemented carbide: A composite material consisting of refractory metal compound (hard phase) and binder metal (bonded phase) produced by powder metallurgy.

Basic characteristics of cemented carbide:

1. High hardness and high wear resistance

2. High modulus of elasticity

3. High compressive strength

4. Good chemical stability (acid and alkali resistance, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient, thermal conductivity, electrical conductivity and similar to iron and its alloys

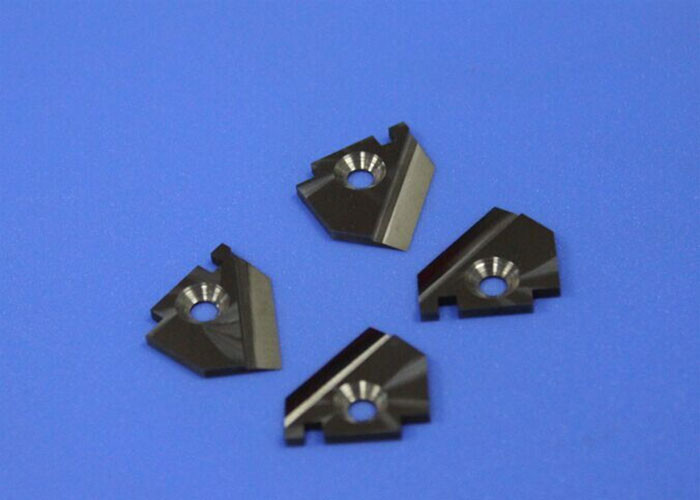

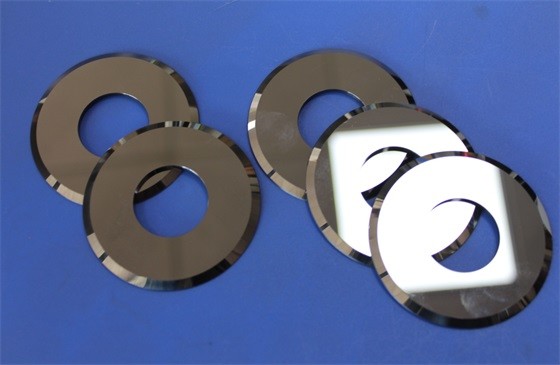

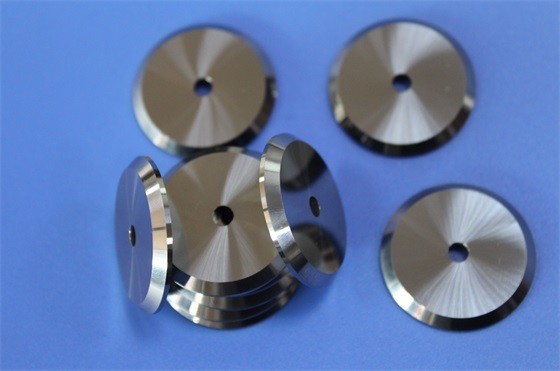

Application of cemented carbide: modern tool materials, wear resistant materials, high temperature and corrosion resistant materials.

Advantages:

Our company can customize all kinds of hard alloy (tungsten steel) non-standard shaped parts according to the drawings or samples provided .

The concept of cemented carbide: A composite material consisting of refractory metal compound (hard phase) and binder metal (bonded phase) produced by powder metallurgy.

Basic characteristics of cemented carbide:

1. High hardness and high wear resistance

2. High modulus of elasticity

3. High compressive strength

4. Good chemical stability (acid and alkali resistance, high temperature oxidation)

5. Low impact toughness

6. Low expansion coefficient, thermal conductivity, electrical conductivity and similar to iron and its alloys

Application of cemented carbide: modern tool materials, wear resistant materials, high temperature and corrosion resistant materials.