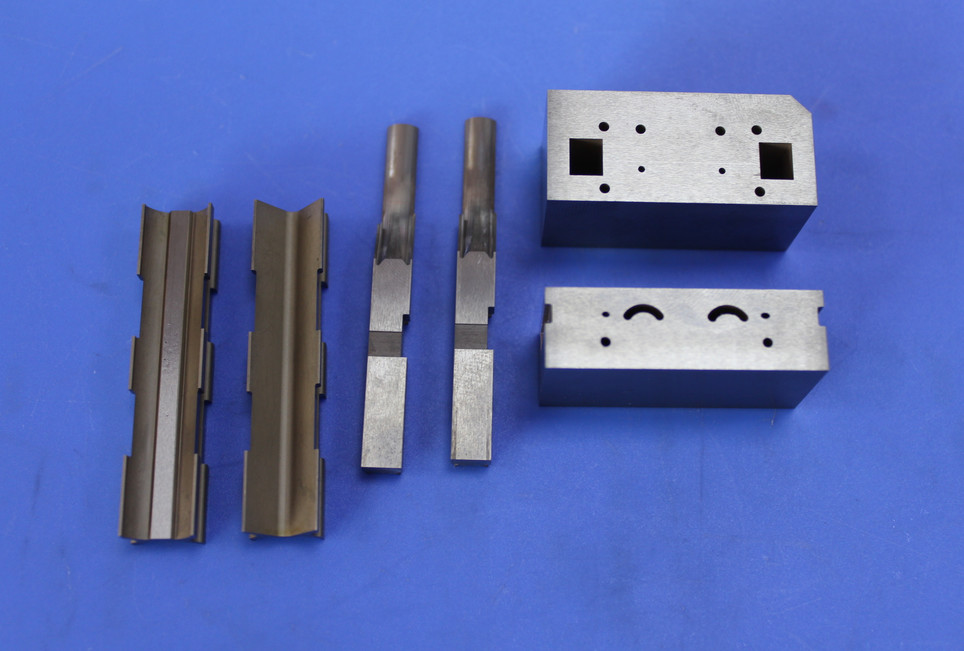

High Hardness Tungsten Carbide Punch , Long Tungsten Carbide Tools

Tungsten Carbide Punch Introduction:

Our company locate in Zhuzhou, Hunan Province, which is known as the hometown of hard alloys. We not only have strong technical research and development capabilities, but also have advanced cemented carbide production lines. We have precipitated in the research of military alloy technology and carbide mold materials for over 60 years. We can undertake the finishing and machining of various carbide molds.

Tungsten Carbide Punch Technical parameters:

Technical parameters of cemented carbide drawing die

| Grade | Density: g/cm³ | Bending strength: TRS | Hardness: HRA or HV | Porosity | Performance and application |

| SXL03 | 14.95~15.11

15.15~15.35 | 1130~1300 | 91.5 | | with good wear resistance, mainly used to make small-sized drawing molds. |

| SXL06 | 14.88~15.04

14.85~15.05

14.0~14.95 | 1530~1550

1580 | 89.5 | 2.0~1.6 | With good wear resistance, used for drawing molds of steel with drawing diameter of 20mm or less, and of carbide, non-ferrous metals and carbide wires or bars under 35mm. |

| SXL08 | 14.65~14.85 14.65~14.85 | 1840~2100 | 89.0 | 2.0~1.6 | With good toughness and wear resistance, used for drawing molds of steel with drawing diameter of 50mm or less, and of carbide, non-ferrous metals and carbide wires or bars under 30mm. |

| SXL30 | 14.29~14.49 | 1910 | HV:1210 | | With excellent strength and toughness, mainly used for drawing molds for workpiece pipes and rods. |

| SXL50 | 13.86~14.06 13.95~14.15 | 2060~2220 | 86.5 | | With excellent strength and toughness, mainly used for drawing molds for workpiece pipes, rods and plates. |

Tungsten Carbide Punch Advantages:

The professional material engineer selects the material grade and superfine particle raw powder according to your requirements.

Advanced precision processing equipment + unique process.

High wear resistance, long service life, greatly reducing the frequency of edge grinding and maintenance.