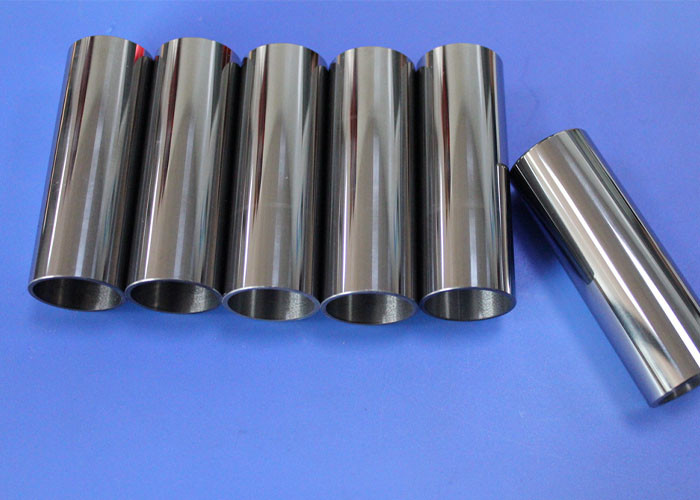

High Hardness Tungsten Carbide Seat / Cutting Tungsten Carbide Tools

Tungsten Carbide Seat Introduction:

Product Name | High Hardness Tungsten Carbide Seat / Cutting Tungsten Carbide Tools |

Status | stress release,HIP treated |

Product status | nickel white,tungsten black |

Standard | OEM |

Grade | YG6, YG6X, YG8, YG8x, YG8A, YG8N, YG10, YG13X, YG13, YG15X, YG15, YG18X, YG18, YG20, YG20C, YG25, YG25C, YN7, YN9, YN13, YN15, YN18, YN20,YN25 |

Specification | customized |

Surface treatment | blank,ground,polished&as requirement |

Feature | Hard hardness,wear resistance,corrosion resistance,toughness,shock resistance |

Tungsten Carbide Seat Technical parameters:

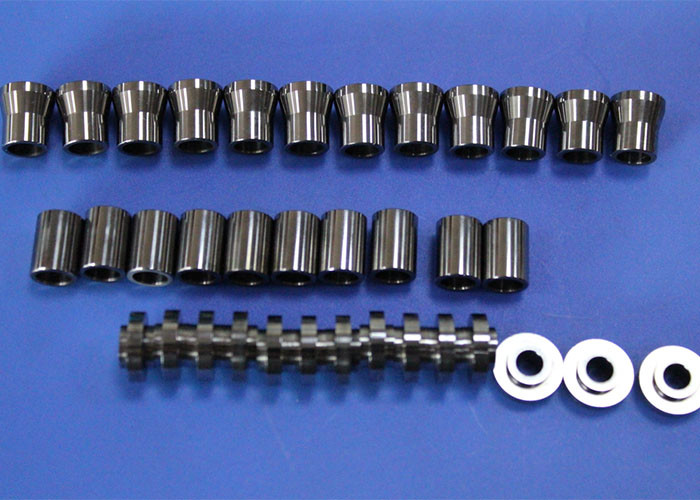

The bending and punching die assembly is mainly composed by bending and punching, bending and punching slider, bending and punching entering, etc. It requires CNC equipment,by wire cutting, grinding, electric spark and such procedures to achieve the dimensional requirements.

Tungsten Carbide Seat Configuration advantage:

We can produce tungsten steel non-standard die, especially can meet the special requirements of internal thread precision machining operations. The high wear resistance is the basic requirement of tungsten steel products. The tungsten steel die material is durable even in the cooperative operation of the progressive die, the combined die and the multi-station die. As a tool material, cemented carbide is a good choice for mold products due to its high hardness, high strength and high wear resistance. We provide non-standard tungsten steel die according to the actual operation requirements, taking the customer's specific drawing as the accuracy tolerance standard.

After-sales service:

The processing procedures of bending and punching die components is not only to master every detail of the machining process, but also to strictly control the finished product inspection to ensure the dimensional tolerance accuracy according to the drawing parameter. This is not only the need to exquisite and perfect production and processing experience, but also the need for advanced and high-quality testing equipment and rich experience. The precision work involving tungsten steel processing and cemented carbide production takes a long time, and the risk of scrapping rate is high. For this reason, customers with the need of precision tungsten steel parts need to contact us in advance to avoid delaying normal production operations.