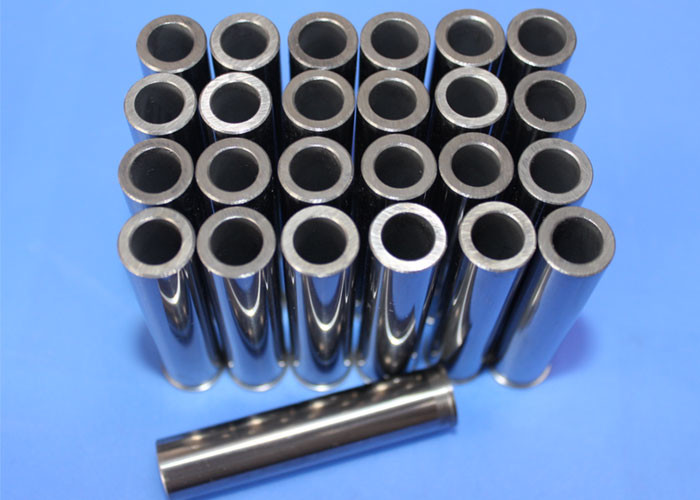

High Hardness Tungsten Carbide Sleeve For Petroleum Machinery Bearing

Tungsten Carbide Sleeve Introduction:

The Tungsten Carbide Sleeve is produced for petroleum machinery bearing pipe sleeve of wear-resistant and corrosion-resistant.

The demand for high-performance mold products in modern manufacturing has become an important method to improve production efficiency and economic development. For example, for the energy production industry, the high-quality equipment is the basic requirement for ensuring the long-term and safe operation of energy production lines. Thus, the performance requirements for mold products have become an inevitable focus. It is the high-end products of cemented carbide molds that have great promotion effects to aerospace, automotive, and downhole drilling industries. The corrosion resistance, high temperature resistance and wear resistance of carbide shaft sleeves and carbide molds are the basic requirements for the long-term operation of energy production machinery. Especially, precision petroleum mechanical alloy bushings with high dimensional accuracy require strict and careful production and processing operations.

The demand for high-quality mold products in industrial production is an inevitable requirement for social and economic development, and it is also the demand for high-end material in the equipment manufacturing industry. The petroleum machinery equipment is developed by our customer, an equipment manufacturer. The equipment has complete management system and has obtained quality certification. Moreover, it has obtained 4 using rights of API 16A, 16C, 6A and 16D issued by American Petroleum Institute. It also has the production license for BOP and BOP control device. Its main products: complete well control equipment, complete cable/wire spray preventer, complete wellhead fracturing equipment, test equipment, and complete set of non-pressure wells. There are seven series and many products are at the domestic leading level.

| Name: | Tungsten Carbide Sleeve | Pin Ceramic Nozzle: | Costum |

|---|

| Tungsten Steel Slider Insert Head: | Costum | Type: | Petroleum Alloy Sleeve |

|---|

| Model: | Carbide Bushing | Application: | Petroleum Machinery Bearing |

|---|

Tungsten Carbide Sleeve Technical parameters:

Mold is a major industrial equipment. As an important means in the industrial production and as the direction of technological development, the mold manufacturing industry depend to a large extent on the development of modern industries and the improvement of the technical level. As an auxiliary equipment for the petroleum industry, our company also provides high-quality tool products for oil drilling of Bohai Oilfield. The key component of the product must have acid and alkali corrosion resistance, high wear resistance and high impact characteristic. These requirements are to meet the demand of drilling engineering. Carbide bushings is a good choice of the petroleum machinery wear-resistant mold series for its excellent performance. The cemented carbide bushings are produced and processed according to the requirements of petroleum machinery equipment customers. The finished product size is φ73.03×φ57.15× 200

Advantages:

We can provide hard alloy sleeve, hard alloy pipe, carbide liner and other products. we can also provide custom-made processing and non-standard carbide sleeve processing according to customer specific drawings. Conventional carbide casing, carbide pipe and other size specifications are as follows:

1. Large outer diameter: φ74mm

2. Small outer diameter: φ5mm

3. The large inner diameter: φ68mm

4. The small inner diameter: φ0.1mm

5. The length of carbide pipe: 360mm