Water Resistance Tungsten Carbide Mold For Fully Automatic COG Equipment

Introduction:

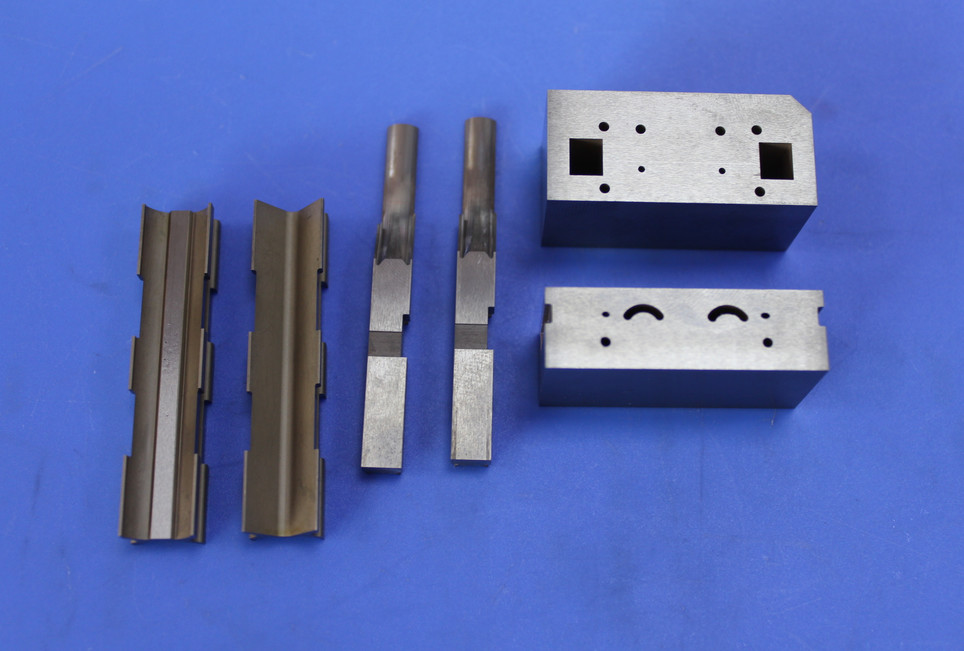

Carbide LCD module indenter, as carbide mold-making product, is hard alloy wear-resistant part. Our company provide LCD module lamination series wear parts according to the drawing requirements for LCD industry equipment. It is made up of the upper indenter and the lower indenter.

| Product Name | High Precision Piercing Carbide Mold Tube Drawing Dies OEM And ODM Service |

| Item No. | punch die |

| Material | TUNGSTEN CARBIDE |

| Size | Customized |

| MOQ | 10PCS |

| Service | OEM and ODM service |

Technical parameters:

The hard alloy LCD module indenter is tungsten steel wear part produced by hard alloy mold. It is used with the wear-resistant parts of the LCD industry. As the industrial tooth, cemented carbide is the first-choice material for wear-resistant parts with its high hardness, high strength and high density. We can provide custom-made upper and lower indenter according to the requirements of customers' drawings.

| Name: | Tungsten Carbide Mold | Pin Ceramic Nozzle: | Costum |

|---|

| Tungsten Steel Slider Insert Head: | Costum | Type: | Carbide Wear Parts |

|---|

| Model: | Carbide LCD Module Indenter | Application: | Fully Automatic COG Equipment |

|---|

Advantage:

As a cemented carbide manufacturer in Zhuzhou, we rely on the cemented carbide production technology and combine with years of production experience and advanced processing equipment to provide alloy molds, carbide wear parts, and hard alloy parts. According to the customer's specific requirements and drawings, we provide the best service to meet the needs of our customers.