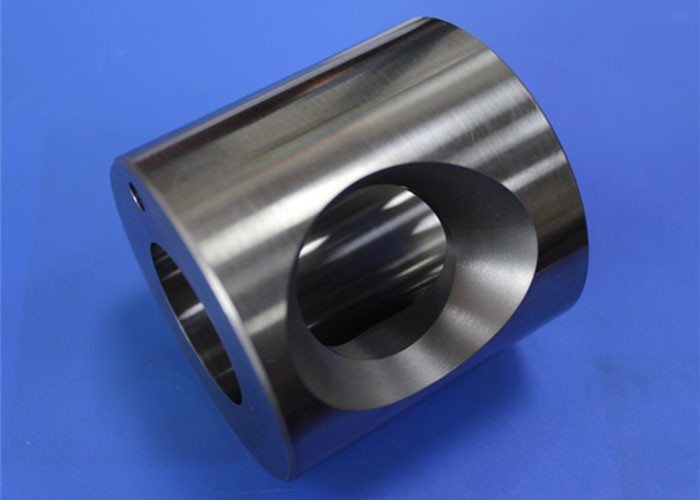

High Precision Tungsten Carbide Processing Valve Seat Power Tool Parts

Specification:

1. High strength, high wear resistance, high precision, good temperature resistance and good corrosion resistance.

2. Mainly used for the sealing of valves of oil pumps in petroleum industry`s containing wells, viscous oil wells, sea oil wells and high pressure sulfur resistant oil wells, etc.

3. Balls and seats are used with compatible cemented carbide valve seats.

4. The finished surface, tolerance standard have reached the standards of the machine industry: G5, G10, G16, G40 and G100 of JB/T 9145-1999.

5. Precision machined cemented carbide balls of other grades and specifications are also available based on customers` demands.

6. Compatible high precision valve seats can also be made.

Carbide die is a high-end die commonly used in the hardware machining industry because the advantages of high hardness, good toughness, high and low temperature wear resistance, low adhesion, good corrosion resistance, high thermal conductivity, low friction coefficient, anti-acid, alkali corrosion resistance, no rust, and easy maintenance. Due to its good toughness, high temperature resistance and high wear resistance, the cemented carbide die has a service life of 10 to 50 times that of a general metal die. Carbide dies are commonly used to make cemented carbide stamping dies, carbide grading dies, powder pressing dies, battery shell stamping dies, stainless steel mobile phone shell stamping dies, bicycle shaft bushings and shaft bowl stamping dies, shaped carbide dies, carbide shrinkage die, carbide wire drawing die, carbide extrusion die, cold die of bolt and nut, frame stamping die, etc.

According to the different actual usage of mechanical equipment dies, we provide a variety of material selection for the cemented carbide dies. The physical parameters of common cemented carbide large- diameter cavity materials are as follows:

1. Grain size (um): 1.0 ~ 2.0

2. Cobalt content (Co%): 8.0 ~ 10

3. Density (g / cm³): 14.41- ~ 14.95

4. Hardness (HRA): 89.5 ~ 93

5. Bending strength (Mpa): 3200 ~ 4500

6. Young's modulus (Gpa): 570 ~ 620

7. Compressive strength (Mpa): 4700

If the customers have special requirements for the cemented carbide dies, we can adjust according to the relevant physical parameters, such as non-magnetic cemented carbide dies have special requirements for materials.

The detailed drawings of the tungsten steel large-diameter cavity are as follows