There are many kinds of cemented carbide blades, including: cut legs blade, v-cut knife, CNC blade, corrugated paper cutting blade, etc. The hard alloy itself has high hardness, wear resistance, strength and toughness, and heat resistance corrosion resistance a series of excellent properties, especially its high hardness and wear resistance, which remain basically unchanged even at a temperature of 500 ° C, and still have a high hardness at 1000 ° C. Carbide inserts accumulate all the characteristics of cemented carbide, so that the carbide insert has the characteristics of being hard to be worn and extremely hard during use.

Corrugated slitting cutters also have many other advantages. At the same time, the cutting blade has a very high requirement on the angle of the cutting edge. While ensuring the sharpness and sharpness of the cutting edge, it is necessary to ensure the strength of the cutting edge. These requirements seem very strict, but they also have very significant significance. of. Only after this heat treatment, the hardness of the slitting blade reaches a very satisfactory effect, which not only reduces its internal stress, but also ensures that deformation does not occur at all during use.

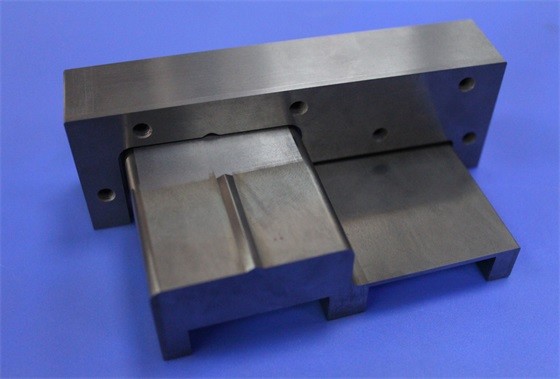

Carbide inserts are one of the categories of carbide tools. Based on metal cutting tool materials, they are widely used as super-hard tools, especially for cutting metal materials. Carbide inserts with excellent performance become the most powerful tool in manufacturing. Carbide inserts are used in a wide range of cutting in the manufacturing industry. They are used in the electronics industry for blades, woodworking tools, CNC tools, welding knives, machine-clamping blades and non-standard shaped tools to meet the production and processing requirements of different industries mainly used in mechanical production and processing. Along with the requirements of economic and social development, coupled with the guidance of the “Twelfth Five - Year Plan” for the high end development of the equipment manufacturing industry, high performance, high addition and high value used carbide inserts have also become the direction of development and application in new fields.

Technical Parameters

1. Ф200×Ф122×1.3 (no hole)

2. Ф210×Ф110×1.4 (no hole)

3. Ф210×Ф122×1.4 (no hole)

4. Φ230×Φ110×1.4 (no hole)

5. φ230×φ130×1.4 (no hole)

6. Φ250×Φ105×1.4-6×Φ, etc.

There are many specifications for slitting blades, which are confirmed in detail according to the specific use. Welcome customers and friends who need to contact

Configuration advantage

Tungsten steel blade professional production and processing factory - Zhuzhou Sanxin Cemented Carbide Production Co., Ltd., based on Zhuzhou cemented carbide production technology, rich experience and professional production equipment, specializing in the production of tungsten steel slitting blades from professional materials according to the customer's requirements. The engineer selects the superfine granules of the applicable grade formula, and the grades are prepared for different uses to meet your different requirements. The internal metallographic products of the rough products are pressed and sintered by high-quality equipment and unique processes. The organization is compact. High hardness, high flexural strength, good impact toughness and corrosion resistance, high chemical inertness, no chipping and curling; high wear resistance, long service life of one machine (5 to 10 times that of general alloy tools) ), greatly reducing the number of frequent tool changes due to the use of general alloy slitting machine blades, thereby greatly improving your production efficiency and reducing your production costs; 3 times cutting edge scientific treatment of fine grinding mirror edge, sharp,the surface of the processing surface is high, the cutting resistance is small, and it is not easy to be damaged. No burrs, rolls, can significantly improve the grade of processed products.