Introduction:

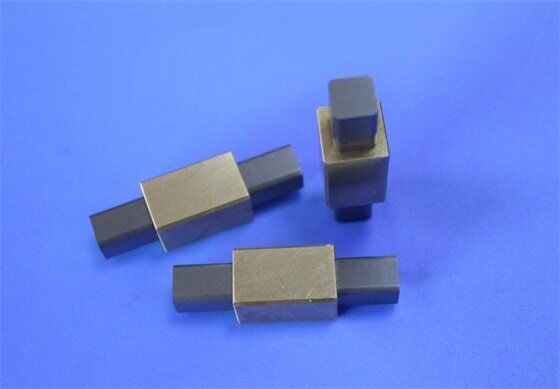

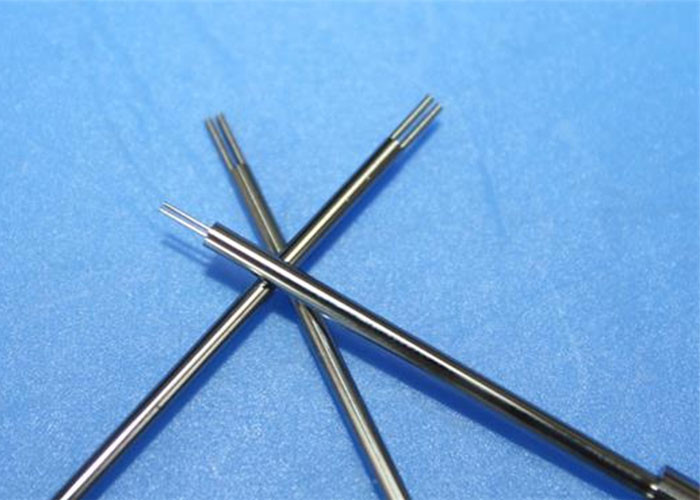

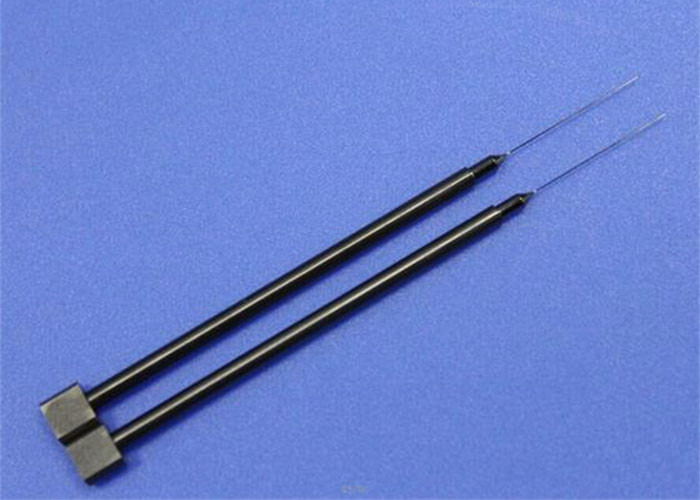

We produce cemented carbide punches, cemented carbide punching needles, cemented carbide non-standard wear-resistant parts series. And we produce twin-column high-speed punch punches for Gree electrical appliances.

As a cemented carbide manufacturer, we have been committed to providing high-performance, high-precision tungsten steel punch series products. We can make different shaped punches, such as tungsten steel punches, cemented carbide punching needles, punching rods, carbide punches in stamping dies, etc. according to different needs of products, especially in progressive die production process. The stamping dies designed according to different stamping materials are different, basically through a plurality of steps of stamping processing to complete a product or semi-finished products. Tungsten steel punches required for different steps have different shapes and specifications, which involves the production of shaped punches for matching stamping dies.

Technical parameters:

We can produce stator and rotor of double-row high-speed groove punching die for the Gree electric appliance 95×64 stator and rotor JM00052 parts drawings. It uses CF-H40S hard alloy material according to the tolerance required.

Advantage:

Materials are the basic requirements to increase production efficiency. As wear-resistant tools for the manufacturing industry, the performance of the carbide punch is excellent, especially for the core working parts of precision machining. The requirement of the carbide punch is higher. As a cemented carbide punch used in precision dies, product consistency is a key factor that directly affects the service life and the dimensional accuracy. The precision requirements for cemented carbide parts are precision. This requires strong technology, rich experience with advanced production equipment and deep processing system to meet the μ precision tolerance.