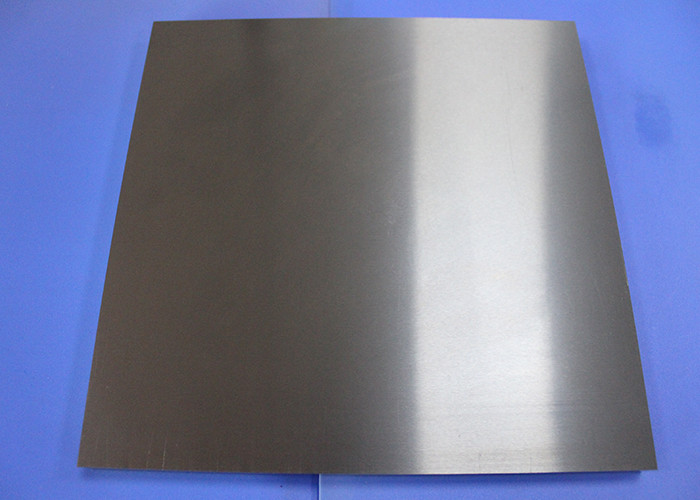

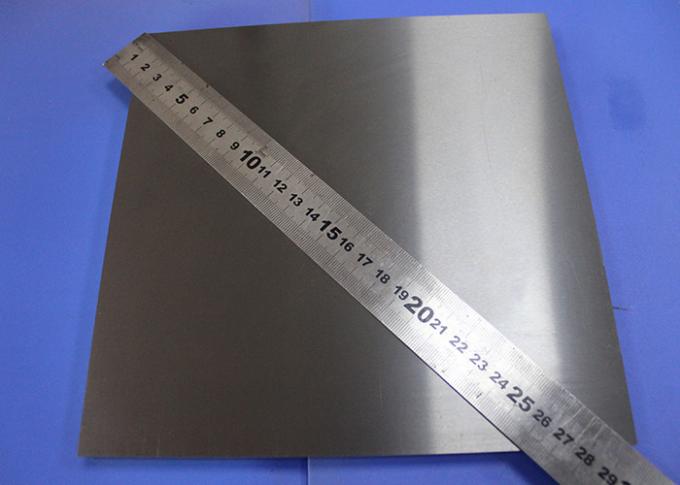

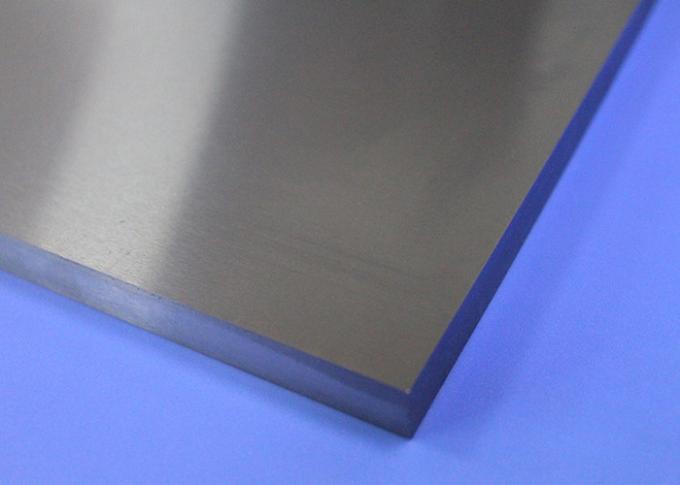

Customized Tungsten Sheet W90NiFe4 Tungsten Steel SheetIntroduction of Tungsten Sheet W90NiFe4

composition:W90NiFe4

Application of Tungsten Sheet W90NiFe4:for making tools

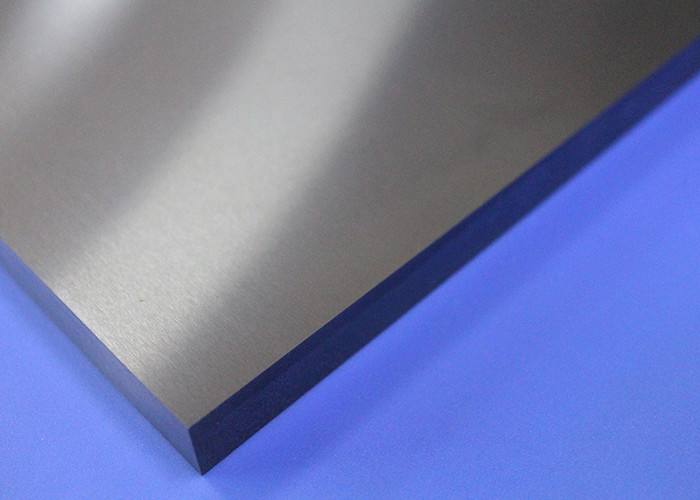

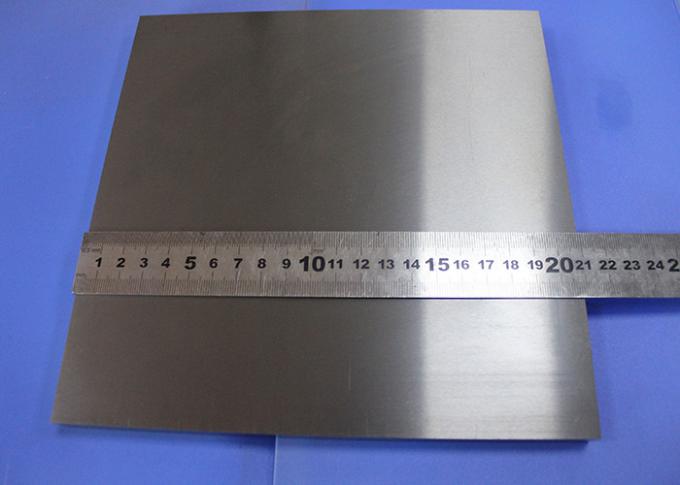

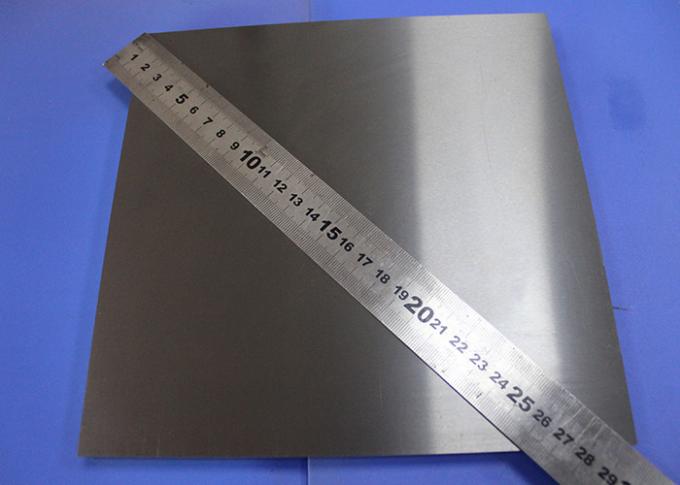

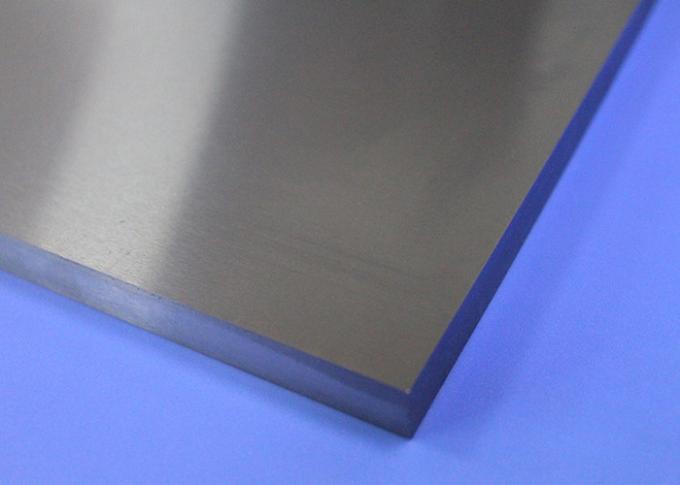

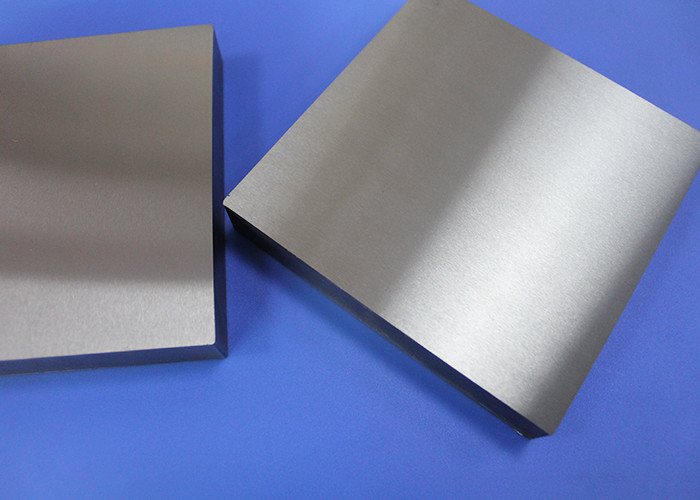

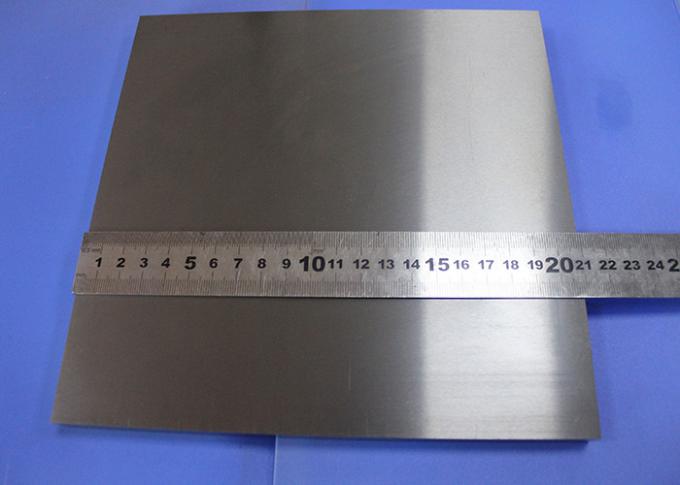

Surface:polished or as customers' requirement

Size:10~30mm or customized

Specific gravity: the general specific gravity is 16.5-18.75g/cm3;

High strength: tensile strength is 700-1000Mpa;

Strong ability to absorb rays: 30-40% higher than lead;

High thermal conductivity: the thermal conductivity of tungsten alloy is 5 times that of die steel;

Small thermal expansion coefficient: only 1/2-1/3 of iron or steel;

Good electrical conductivity; widely used in lighting and welding industries because of its good electrical conductivity;

Has good weldability and workability.

Technical parameters:

From raw material production to finished product processing, the hard alloy insert pins of our company are complete and perfect. The whole project is based on the cemented carbide production process. The ingredients are mixed thoroughly → pulverized → dried → sieved, then added to the forming agent → re-dried → sifted to obtain the mixture → pressing the mixed granulation → forming → low-pressure sintering → sintered blank → inspection (non-destructive ultrasonic testing) → blank dimensional accuracy inspection → EDM (or wire cutting) → rough grinding → fine grinding → polishing → inspection → marking → packaging. Mass production of carbide insert pin requires product consistency, which directly affects production efficiency. Carbide punching pins produced by our company, whether it is custom-made or mass-produced, always controls each processing procedure to ensure the consistency of the carbide insert pins.

The carbide insert pins of our company use high-quality grade alloy materials. The physical parameters are as follows:

1. CO content: 10% ~ 12%

2. Density (g/cm³): 14.0 ~ 14.5

3. Hardness: 89 ~ 92.0 HRA

4. Grain size: 0.6 ~ 1.2 um

5. Bending strength: 4000MPa

6. Modulus of elasticity (GPa): 490.

7. Thermal expansion coefficient 10-6/0C: 5.4.

8. The dimensions and specifications of the carbide insert pins are customized according to the drawings, and the precision requirements can be ±0.001.

Advantages:

Our company is specializing in producing and manufacturing hard alloy insert pins for precision mold customers. It is used with electronic ceramic injection molds. The precision requirements are very high, and the perfect consistency of products is the primary standard of this set of products. The tungsten carbide punching pin equipped in electronic ceramic precision mold is used in large number, and each insert pin is required to maintain good consistency. This requires that the finishing process must strictly control each processing procedure. Our company can produce the hard alloy insert pins according to the requirements of the precision mold manufacturer. The consistency of the products can be guaranteed, and the tolerance requirements are +0.002. The finish of the punch needles is required to be 0.2, which meets the highest requirements of applications in electronic ceramic injection molds.