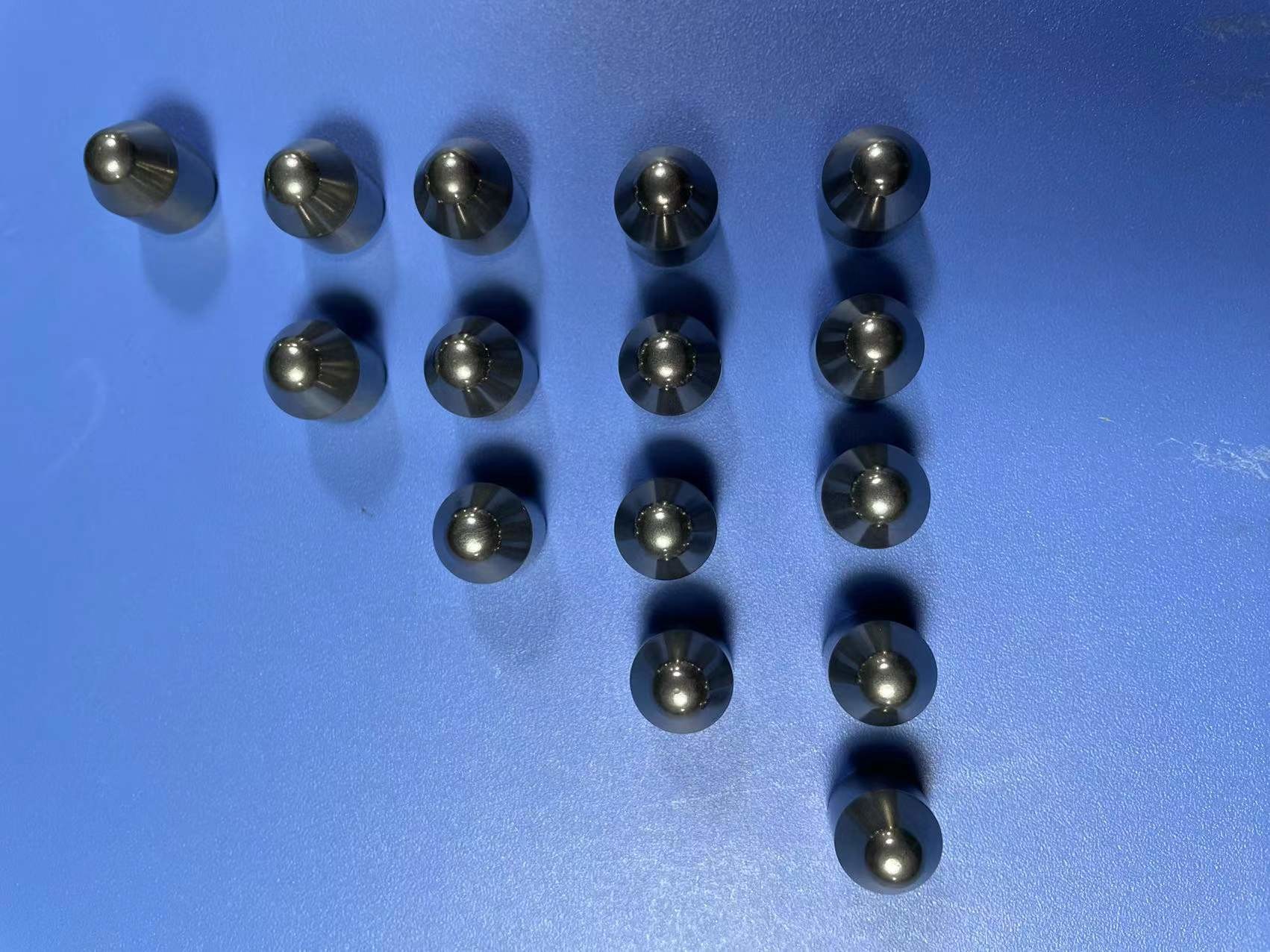

Tungsten Carbide Inserts for Shield Tunneling Boring Machine Head

Key Points:

| Size | φ18*φ16*r5*30 |

| Assembling Units | 30-40 units or more for operation |

| Assembling way | Be bolted |

| Replacement | Be replaced from the soil backroom behind the machine head |

| Requirement | Good impact resistance and wear resistance |

Tungsten Carbide inserts, carbide buttons, are experts for tough hard rock.

As industrial teeth, is a good choice for wear resistant tools. They are assembled for shield tunneling boring machine head.

Generally, a group of shield machine head loaded 30-40 units or more for operation based on the use of shield mechanical equipment. And, tungsten carbide inserts are bolted and can be replaced from the soil backroom behind the machine head.

It has complex application environment, engaged in underground tunneling, used in tunnel, subway and other projects with unclear geological components, and high-power equipment such as propulsion force and shear force, which requires the tungsten carbide inserts to have good impact resistance and wear resistance. The size specification is: φ18*φ16*r5*30

Mainly Usage:

Tunneling Boring Machine, in short, TBM is the ideal machine for tunnelling in hard rock, like building subway, railway, highway, municipal, hydropower and other tunnel projects.

And according to different geology of the "tailored" type of design and manufacturing, the reliability requirements are extremely high.