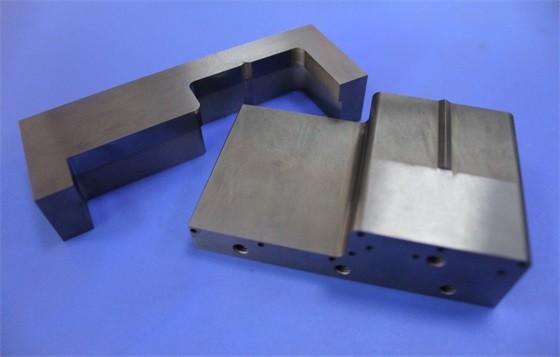

As industrial teeth, the excellent properties of tungsten steel mainly include high hardness, good wear resistance, high strength and toughness, heat resistance, corrosion resistance, etc., especially its high hardness and wear resistance, it is widely used for impact and pulling and stretching operation. Tungsten steel tools are widely used in the manufacturing industry, such as V-CUT blades, cut legs blades, turning tools, milling cutters, planers, drills, boring tools, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and ordinary steel, it can also be used to cut difficult processing material such as heat resistant steel, stainless steel, high manganese steel and tool steel. As a well-known brand in the industry, Zhuzhou Tungsten Steel Tool leads the cutting tool market.

Tungsten steel tools with integral tungsten steel as the base material are also used as one of the superhard tools. They are also called carbide tools. They are commonly called tungsten steel tools in coastal areas and Taiwan. The excellent performance makes cutting tool widely used in manufacturing. It is also a powerful cutting aid for modern industry.

Zhuzhou tungsten steel tools started early and developed rapidly. The complete tungsten steel tool industry chain cluster has been gradually improved to meet the needs of the current economic and social development of manufacturing of metal cutting tools. Zhuzhou Sanxin Tungsten Steel Tool has many years of experience in the production of Zhuzhou tungsten steel tools for customers who have demand.

Technical Parameters

Tungsten steel tools, ie hard alloy tools, are super hard tools that are machined from the edge of the whole tungsten steel material by precision machining. They are widely used in the production and machining of cutting tools with their excellent performance.

The technical characteristics of tungsten steel cutters are mainly:

1. Cutting sharp, high hardness, high wear resistance,

2. High modulus of elasticity

3. High compressive strength

4. Good chemical stability (acid, alkali, high temperature oxidation)

5. Low impact toughness

6. The expansion coefficient is low, and the heat conduction and electricity conduction are similar to those of iron and its alloy.

Tungsten steel cutting tools are widely used in the manufacturing industry. They are used in the electronics industry for cutting tools, woodworking tools, CNC tools, welding knives, machine clamping tools and non-standard shaped tools to meet the production and processing requirements of different industries. Along with the economic and social development requirements, coupled with the guidance of the “Twelfth Five Year Plan” for the high end development of the equipment manufacturing industry, high performance, high addition and high use tungsten steel tools have also become the direction of development and application in new fields.

Zhuzhou Tungsten Steel Tools is based on quality, focusing on the brand, providing wealth cutting tools for high-quality tungsten steel tools for manufacturing and processing.

Configuration advantage

Zhuzhou Sanxin tungsten steel cutter is based on Zhuzhou tungsten steel production technology, solid backed by Zhuzhou tungsten steel industry, focusing on tungsten steel cutting products.it is guided by market demand, taking customer satisfaction as the test standard. Professional knife, there must be a trick, the tungsten steel cutters produced by our company can be customized according to the specific requirements of customers and drawings.

After sales service

Based on quality, focusing on the brand, Zhuzhou Sanxin tungsten steel tools focuses on every detail of the tungsten steel tool production process and promises to solve the metal cutting quality program for customers and friends. Choose the most suitable tungsten steel tool grade for the use of tungsten steel tools for different cutting operations.