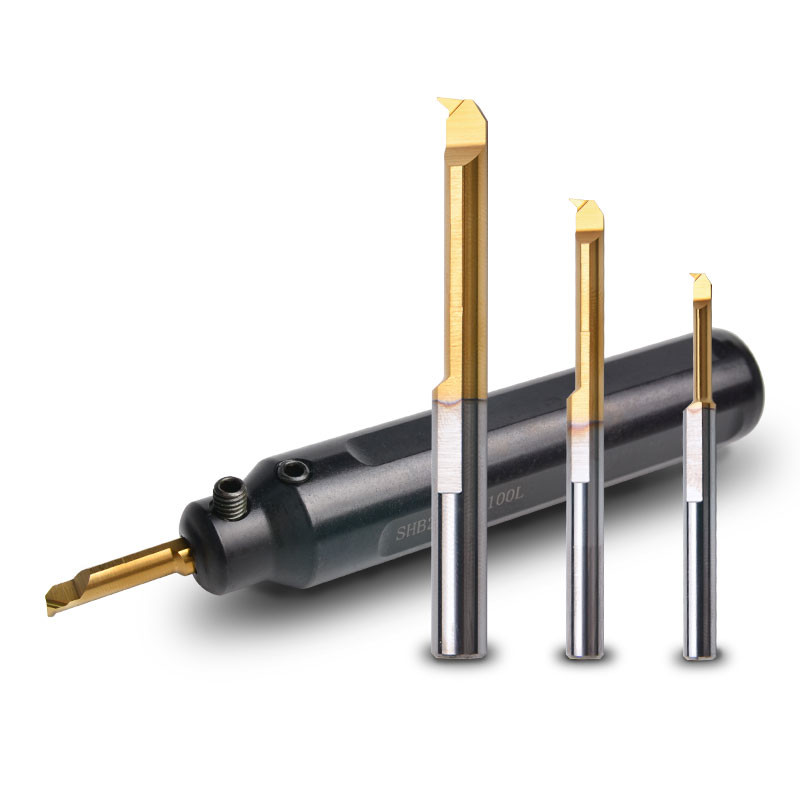

Inner Hole Boring Tools MQR,Tiny Profiling Tools for Grooving Stainless Steel etc

Drow_Carbide_Boring_Tools_EN.pdfDrow_Carbide_Boring_Tools_MD_EN.pdfApplication Field:

MQR is an internal boring and turning tool , widely used for profiling and grooving finishing in Mini Turning Lathe. Mainly suitable for machine tools like CNC lathes, centering machines and so on. It is ideal for semi-finishing&finishing turning of a wide range of materials, particularly stainless steels and various alloys etc.With advanced nanometer coating on ultrafine carbide, this tool offers high wear and buildup resistance, gives you a smoothy and efficiency machining experience.

Product Details---Profiling Tool MPR- Tool Material : 100% virgin tungsten carbide.

- Usage: For inner hole turning,grooving and profiling finishing.Suitable for Mini CNC lathe and so on.

- Tool production : Our strong R&D power and high-end equipment can always meet your requirement.

- Hardness: HRA91~93.5

- Accuracy: ±0.005mm

- Coating : PVD or TIN+TIALSIN or to be defined per your application. Smooth fine surface of PVD coated carbide provides good surface finish. Achieved high reliability in the unstable processing field of stainless steel.

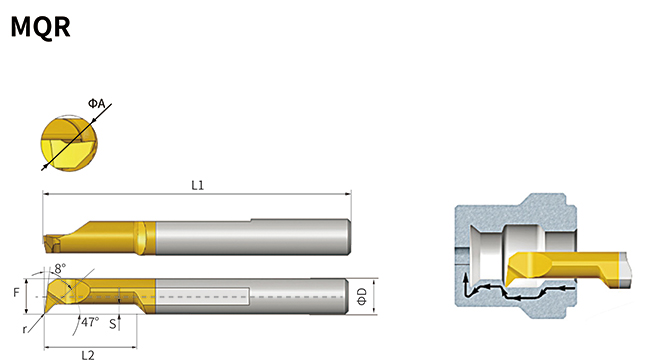

- Mainly Difference to MPR: Bigger tips dip angle(47°) than MPR( 22°).

As for finished product of MPR , specific product information as below:

| Brand Name: | Drow |

| Model Number: | MQR Profiling tool |

| Customized support: | OEM, ODM, OBM. |

| Standard: | ISO |

| Product type: | Solid carbide boring tiny tool |

| Material: | 100% virgin tungsten carbide |

| Coating: | To be defined, with or without coating, Nano coating |

| Hardness: | HRA 91~93 |

| Flute length: | 10~30mm |

| Flute color: | Gold |

| Precision: | ±0.005mm |

| Shank diameter: | 4.0~8.0mm |

| Shank type: | round shank |

| Tip arc: | R0.10-R0.20 |

| Sample Order: | Accepted |

| Usage: | Internal turning,grooving and profiling for finishing |

| Workpiece Material: | Steel,Stainless steel,Cast iron and so on |

| Machining type: | Semi-Finishing/Finishing |

Product Features:

1. Smooth chip evacuation and efficient machining

2. The boring tool is integrally formed

3. Imported machine tool precision grinding

4. Nano coating is wear-resistant and durable

5. Round shank design, tightly bonded, with internal coolant of Drow tool sleeve, improve efficiency and service life, reduce times of tool changes

Product Specification:

| Model | Minimum diameter of machining hole(mm)ΦA | ΦD | r | L1 | L2 | F | S |

|---|

| MQR3R0.1L10 | 3.1 | 4 | 0.10 | 40 | 10 | 2.8 | 0.60 |

|---|

| MQR3R0.1L15 | 3.1 | 4 | 0.10 | 46 | 15 | 2.8 | 0.60 |

|---|

| MQR4R0.1L12 | 4.1 | 4 | 0.10 | 46 | 12 | 3.8 | 0.80 |

|---|

| MQR4R0.1L20 | 4.1 | 4 | 0.10 | 50 | 20 | 3.8 | 0.80 |

|---|

| MQR5R0.15L15 | 5.1 | 5 | 0.15 | 50 | 15 | 4.8 | 1.00 |

|---|

| MQR5R0.15L25 | 5.1 | 5 | 0.15 | 60 | 25 | 4.8 | 1.00 |

|---|

| MQR6R0.15L20 | 6.1 | 6 | 0.15 | 50 | 20 | 5.8 | 1.20 |

|---|

| MQR6R0.15L30 | 6.1 | 6 | 0.15 | 60 | 30 | 5.8 | 1.20 |

|---|

| MQR8R0.2L30 | 8.1 | 8 | 0.20 | 65 | 30 | 7.8 | 1.50 |

|---|

Our Advantages:

1. High quality and higher tool life

2. Reply timely

3. Comprehensive Service

4. OEM/ODM/OBM support

5. Competitive price

Quality Inspection

1.Projector detection

2.ZOLLER detection

3.Swis edging

4.German forging difference process detection

5.Edge passivation detection

6.Coreless grinding

FAQ

Q1:Do you produce special cutting tools?

A: Yes,we specialize in customized cutter fabricate and translate the most complex cutting idea into reality, tools manufactured by us are designed and customized for various demanding applications and variety materials!

Q2:why should you buy from us not from other suppliers?

A: We Drow devote ourselves in research and development of tungsten carbide, cutting tools, cutting inserts, and new materials, specializing in the design and production of boring tools, carbide turning inserts , indexable inserts, CNC inserts etc.

Q3:If we want to cooperate with you, is it possible to get confidentiality?

A: Sure, all your information including company info, drawings, PO details will be kept confidential, we can signed NDA if you want (non disclosure agreement).

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q5: what can you buy from us?

A: Carbide insert,carbide end mill,carbide drill,carbide boring,cutting tools&customized carbide precision molds.